PET Preform Mould PET Preform Injection Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

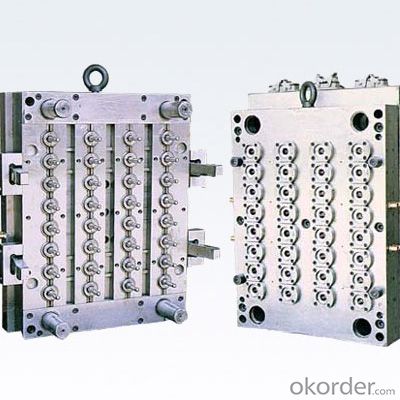

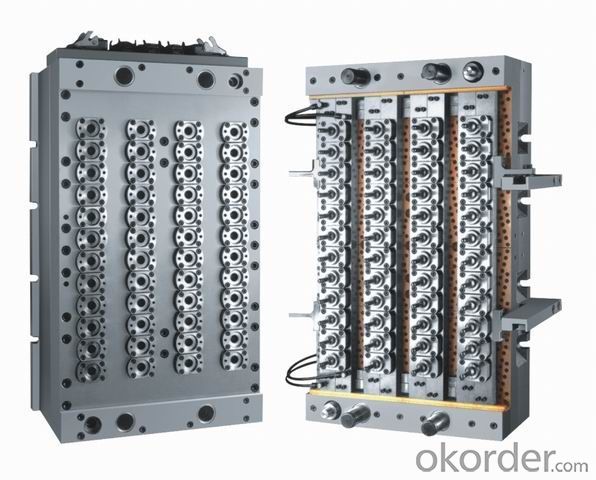

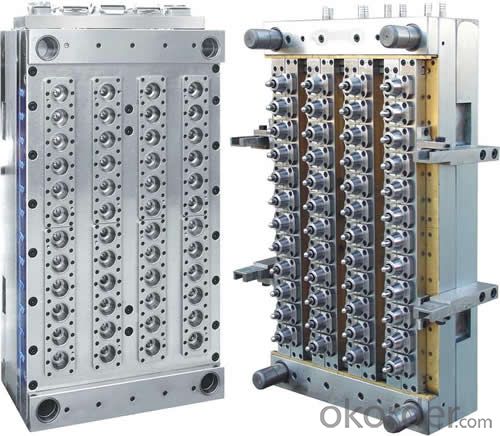

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Design to production of mold, 100% made in Taiwan.

. The SGS RoHS Certification Mark demonstrates our commitment to quality and achieving consistent production.

. Excellent in interchangeable cores molds design.

. Surface finish with high gloss polishing.

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

. Can supply with both Mold & Molded parts

. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q:The stamping dies at the Angle of 90 degrees, the Angle is big or small how to repair.

- The recommended answer is quite different. Bending 90 degrees is supposed to have both internal and external conditions. The inside is less than 90 degrees, and the outside is greater than 90 degrees. This is the question of the gap and the rebound. This is in the normal model domain. General modulators and mold engineers know how to handle it. R and not R also affect this. In the case of the block under zero, the probability of a general Angle is reduced. But absolute zero is bad, can cause product scratches serious. Typically, the master moduler will be a little bit more angular, and if you do a zero, he will also get around R0.2. The solution to this problem is one packet of R processing. Adjust the bending clearance. 3 below the forming block. The moulding male is left straight after two to 3 degrees. Adjust bending clearance and so on. This is the basic problem of stamping die! I didn't elaborate on what to do, but if you were doing molds, according to the ones I was talking about, it would be easy enough to fix the problem. There are several other forms of prototyping. Each has its own merits. You know, it's not a good idea.

- Q:What is a mold, and what is a mold

- Under external force, the material is made into a special shape and dimension. Widely used in cutting, forging, cold heading, extrusion, powder metallurgy parts suppression, pressure casting, as well as engineering plastics, rubber, ceramics and other products of the molding or injection forming. The mold has a certain contour or inner cavity shape, and the shape of the blade can be separated by the shape of the outline. The inner cavity shape can be used to obtain the corresponding solid shape. The mould usually includes two parts: the moving model and the mold (or the punch and the concave), which can be divided into two parts. When apart, take out the pieces and put them into the mold cavity forming. Mold is a precision tool, complex shape, bear the expansion force of billet, the structural strength, stiffness, surface hardness, surface roughness and machining accuracy have higher request, the development level of mold production is one of the important symbol of the levels of mechanical manufacturing. There are many kinds of molds, according to the processing object and the processing technique can be divided into: the mould of processing the metal. The mould of non-metal and powder metallurgy. Including plastic mold (such as injection mould, die mold and extrusion die), rubber mould and powder metallurgy mold etc. According to the structural characteristics, the mould can be divided into flat blanking modes and spatial modes. The mould is usually single, small batch production.

- Q:What is the difference between mould injection and blow molding?

- Injection molding is used to make the mold and then inject the plastic into the mould. Blow molding is used to make a good plastic moulds after heating softening in the embryo, the embryo within the join high pressure air, thinning of the tensile softening of the embryo, formation and mould the same products. Injection molding can make a very complex plastic product, and you can say what shape you want to make. Blow molding can only make hollow products, such as drink bottles and some tool boxes. The moulds are very expensive and the processing is more expensive. Blow molding and processing are cheaper

- Q:What does the mold slow wire do

- Is walking wire edm wire cutting is a kind of English abbreviations (WEDM LS) is the use of continuous moving fine wire electrode (called wire electrode), pulsed spark discharge of artifact removal in metal, cutting shape. It is mainly used for processing of complex shape and small precision of workpiece, according to different wire electrode material (one is molybdenum wire, one is the copper wire), wire cutting machine tool is usually divided into two kinds: one kind is walking wire (wire electrode is copper wire), wire electrode for low-speed one-way movement, the general wire walking speed is lower than 0.2 m/s, the accuracy of 0.001 mm, and close to grinding surface quality level. The electrode filament is not used after discharge, the job is smooth, uniform, jitter and the quality of processing is better. Moreover, advanced power technology is adopted to achieve high speed processing, with maximum productivity of 350mm2 / min

- Q:How many types of molds? Please help me out!

- The mold can be divided into metal mould and non-metallic mould according to the material that is formed. The metal mould is divided into: casting mould (non-ferrous metal casting, steel casting) and forging die etc. Non-metallic mold is also divided into: plastic mould and inorganic non-metallic mould. And according to the material of the mould itself, the mold can be divided into: sand mold, metal mould, vacuum mold, paraffin mold and so on. With the rapid development of polymer plastics, plastic mould is closely related to people's life. Plastic mould can be divided into: injection molding mold, extrusion molding mold, gas auxiliary molding mould and so on.

- Q:The characteristics of cold making die steel

- High hardness, high wear resistance, high malleability, high yield strength

- Q:Do machine parts need to be moulds?

- Not all of them have to be moulds. Look at your parts.I hope my answer will help you

- Q:Why is the mold selected for quenching?

- This is mainly due to the steel in the range of the solid as the change of heating temperature and cooling speed, organization structure change, so the use of different heating temperature and cooling rate to control or change the organization structure steel, can get different performance. (a) prepare heat treatment, annealing, normalizing heat the steel to the phase transition point above a certain temperature, heat preservation time, and then slowly along with the furnace cooled to 500 'C below, after cooling in the air. So you get an approximate equilibrium organization, and it's called annealing. The so-called positive fire is to heat a piece of steel to a certain temperature above the point of phase change and then remove it from the furnace and cool it in the air. Annealing or normalizing and technical requirements of the parts service condition has no direct relation, but simply brought by the procedure in order to improve the defects, and organization prepare for the next procedure, make the grain refinement, eliminate the internal stress of normalizing, annealing, etc. When the fire is hot, it cools quickly; Slow down when annealing. Annealing reduces the hardness of the material; Positive fire can improve the hardness of the material. After normalizing steel hardness is larger than that of annealing steel hardness is high, so in order to facilitate machining, the carbon content of high carbon tool steel materials such as using the annealing treatment. In order to reduce the hardness.

- Q:The wall thickness of the die is affected by the plastic parts

- Different plastic minimum wall thickness is different, small yu this wall, even if the uniformity also cannot be done The thin wall is difficult for the top, the layout of the thimble, the big and big.

- Q:What is the difference between the mold and the numerical control? The difference is?

- Numerical control is for mould service. Numerical control general index control lathe and CNC milling machine, the basic processing of die is done by numerical control, such as shape and the basic shape of product area. Processing of the details by the molder.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PET Preform Mould PET Preform Injection Moulding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords