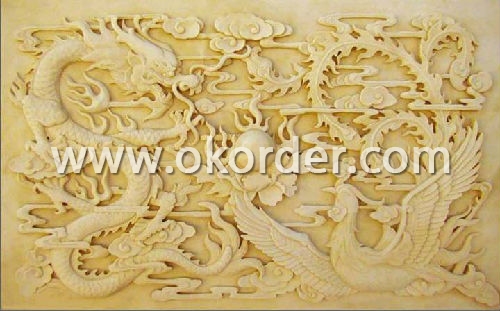

Pediment Ornament Mould For Wall Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction Of Pediment Ornament Mould For Wall Decoration:

GRC material has excellent constructive performance in history of building construction. With high strength and good nature, it is fireproof, mildew and worm resistant, moisture proof, and sound and heat insulated. It can be processed by nailing, adhering and patching, thus it is easy and convenient in construction.

Description Of Pediment Ornament Mould For Wall Decoration:

High strengh

Corrosion resistance, anti-frost and waterproof

Natural and hand crafted

Durable

Component Of Pediment Ornament Mould For Wall Decoration:

Glass Fibre Reinforced Cement(Cement, Alkali Resistant Glass Fibre / protofilament), short for GRC/GFRC

Advantage Of Pediment Ornament Mould For Wall Decoration:

Strong, Tensile-strength: 1800 Mpa, twice to triple as much as that of steel fibre.

S. G.: 2.7

Durability: Over 10 years

High heat-resistant: Its softening point is about 860

Anti-frost, waterproof&fireproof, mildew&worm and corrosion resistance

UV-protection&environment friendly

Maintenance free

Customer designs are available. Our products are very popular with domestic and abroad market. We have built a steady and long-term cooperation relationships with Chinese top 20 real estate companies and our products are exported to the Middle East, Western Europe, North America, South Africa and other countries and regions.

- Q:if so, are there any special steps i need to do?

- I would highly highly (double to really emphasize it) not recommend doing it. Either buy/find rocks or use sand a substrate to replace it.

- Q:Building materials distribution business projects can increase the cement products and steel it?

- Definition of cement: powdered hydraulic inorganic cementitious material

- Q:YES, AND FEET TOO. IVE HEARD THAT SOME quot;CONTRIBUTIONquot; IS INVOLVED, IN OTHER WORDS WANNA BE CELEBS CAN BUY WHAT MAY HAVE ONCE BEEN A GENUINE HONOR. WHO DECIDES AND WHO DOES GET THEIR PLACE IN CEMENT?

- Hollywood Walk Of Fame Criteria

- Q:I was planning on using Hardie Backer, but the instruction state that Hardie Backer is not designed for use over concrete. I need to raise the finished floor height about one inch to match an existing floor. If I can use cement backer board, do I use thin set to attach the backer board to the concrete? If I can't use it, what are my options?

- No .. The only way to build it up to even think about it is to use a thin set under a cement board,and using that much thinset it doesn t have the compression strength . And you cannot properly attach a cement board to cement. Best way to achieve this is to use a mud which is basically using cement to make another floor. You ll need lathe , portland cement and sand . The sand and cement in the proper ratio and mixed to a special dry consistency is then used to make another floor over your slab. Special tricks and method to do this. Care must be taken when doing this over a slab. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:I was walking my dog and there was wet cement on the sidewalk. I was really tempted to write in it, like I see on other sidewalks. I wrote an MC for the town we libe in. Then I immediately regretted it and tried to smooth it out but it looked even worse! I dont know what to do and feel EXTREMELY BAD. If I turn myself in, Im afraid I wount be able to pay the charges. What do I do?!?!?!

- Your fingerprints are etched in cement.

- Q:I want to determine the percentage of Chloride present in any cement. Then can any one tell mePl., the standard method of determination of percentage of chloride in any type of cement.

- figure out what the cement is made of in terms of chemical formula. use Cl5S2 as a rhetorical example *by the way, thats way off, divide the number of chlorine by the the total number of atoms in the formula. so in the example, its 5/ (5+2), which is about 0.714, so in the example there is 71.4% chlorine/ chloride

- Q:When installing fence posts for a 6 foot high privacy fence, I have gotten a few different inputs reference cement. Specifically, should what would you recommend and why: 1) dry pack cement into the hole and don't add water (let nature do it over time; does this jeopardize the plum of the posts initially); 2) dry pack cement into the hole and then add some water; 3) premix and then add to the hole; or 4) use quick drying cement.

- Home Depot Fence Post

- Q:I have an adjustable basketball hoop with a base that you fill with sand. I would like to cement this in the ground instead. Does anyone know if you can buy post extensions for installing it in the ground?

- I would remove the plastic base and cement the post in the ground instead. Just get a longer piece of pipe that fits over/inside the original one to give it the proper length. I believe there is a rule-of-thumb that says for every inch of diameter the pipe has you dig the hole that amount of feet. So, for a 4 diameter pipe you dig a 4' hole. As it is a basketball hoop (which will be moving) I would go larger and deeper.

- Q:I've tried to make the cement (on Whuddle World) and it always says that i'm unable to make it.WHY!?!

- to mix a cement, u need this : 1 bag full of cement a bottle of water ( u need oil to pump water. for oil, just go to gadget n gizmos, enter the 1st lab, click oil can near pink tube) sand ( get it free at playground (NE ww) bucket ( talk to farmer noggin, then search it by clicking around a pile of hay in farmer barn.. keep clicking till you find it) a trowel ( go to hickory hardware n woodworks, click a garden spade which is hanging on the wall. just keep clicking around it till u'll receive msg that wud kraft let u borrowed his trowel) now only u can mix it by clicking ur bucket in ur omnimbus. click use bucket and u now can start mixing it by dragging the items in correct order. 1. bucket, 2. cement. 3. water. 4. sand now u just mix the cement and make sure u carry the it. go to charlie fountain and click the statue. n dont forget to talk to chelsea to receive your awards.. hope this help all whuddles.. cheer up!!!

- Q:Need' to get 20 cement blocks home. How many [weight wise] can I put in the back of a PT Cruiser.? About how much does a 'Nellis' type cement block weight?

- ABOUT 800 lbs. per load !

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2006 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Pediment Ornament Mould For Wall Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords