PE Woven Tarpaulin with Sun-Resistant with Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Tarpaulin

Product | |

Material | PP or PE (Inner HDPE Woven Fabric, LDPE laminated both sides ) |

Weight | 55 GSM / SQ.M ~ 300 GSM / SQ.M |

Width | 2 meter or 4 meter withou joint. Available for wider fabric by heat sealing. Or as the client's requirment |

Denier | 500 ~ 3000 Denier |

Lenght | 50 meter to 200 meter |

Density / sq.inch : | 7X6, 7X7, 8X7, 8X8, 10X8, 10X10, 12X12, 14X14, 16X16 ( 2x3m, 3x4m,3x5m, 4x5m, 4x6m, 5x8m, 6x8m, 6x10m, 2.5x3.6m, 3.6x5.4m, 5.4x7.2m, 7.2x9m, 10x50m.) |

Mesh | 8x8 9x9 10x10 11x11 12x12 14x14 |

Making | a. All edges with PP rope in hem; |

2. Fetures and Application:

sun-resistant,UV treated, lightweight, easy to fold, durable and other characteristics.

Tarpaulin is widely used for truck canopy,ship cover and cargo storage or transportation in mineral factories and ports, also can be used as tents in outside travel and calamities.The tarpaulin is to cover and protect the goods in the open air and avoid the goods get wet.

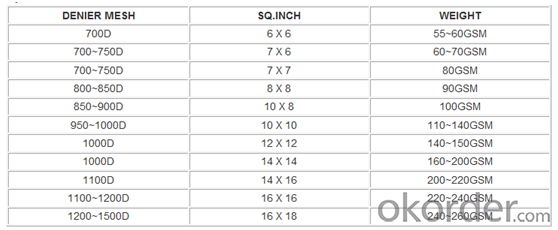

3. Specifications for Tarpaulin

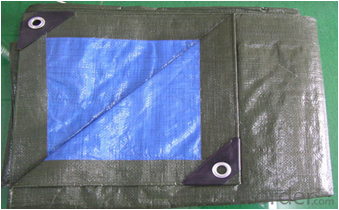

4. Photo for Tarpaulin

- Q:Why do the basics of the cushion waterproofing

- Base cushion waterproofing is not contact with the soil (Ying water) to prevent water into the cushion, but in the cushion and the base of the bottom of the contact, in fact, is the basis of the bottom of the waterproof.

- Q:Is foam concrete suitable for use as a cushion?

- And then through the foaming machine pumping system for cast-in-place construction or mold forming, the formation of natural conservation with a large number of closed pores of the new lightweight insulation materials.

- Q:Is it possible to make a waterproof layer

- 3, waterproof layer set and standard construction methods: to be painted 2 to 3 times, or should be added fiberglass cloth, and each brushing the thickness of the cured material shall not be less than 1 mm, and should be completely dry (about 5 -8 hours) and then the next construction. After brushing, but also in the paint waterproof layer to do a mortar protective layer, and finally paste the tile.

- Q:What is the relationship between the cushion and the ring beam?

- Ring beam is reinforced concrete. Is to increase the overall wall and overall stiffness, improve the side resistance performance, according to the earthquake or masonry specifications set. There may be in the ground wall, there may be in the underground wall.

- Q:What is the difference between leveling and cushion?

- Cushion, the base material is not divided into materials at the same time, the design will be described. Material is the same concrete, the greater than 20CM calculated basis, less than, equal to 20CM calculated cushion. Leveling layer refers to the original structure due to the existence of uneven or slope and the laying of the base layer, is conducive to laying the surface layer or waterproof, insulation layer. The role is to play a leveling, looking for a slope or enhanced function.

- Q:Can the cushion on the prefabricated board floor be dug?

- Surface layer without steel, do not bear the load, you can dig out But sometimes the prefabricated floor above the surface layer with steel, to bear the load, this can not be removed! To know how thick the cushion, in the local dig about In general, to do leveling layer, can not be directly laid tiles

- Q:The top floor made waterproof playing cushion layer of how to do

- 3. The first layer to do a flexible waterproof, try the valve Bai fat together with the full bricks that are roof-specific anti-aging waterproof coating.

- Q:Large area ground concrete cushion seam Why is the separation of joints generally concrete

- Second, sub-grid seam set In order to reduce the total shrinkage and temperature stress of the large area waterproof layer, avoid the leakage of the waterproof layer due to the deformation of the structural layer and the change of the temperature and humidity, the waterproof layer should be divided according to the shape, size and structure of the flat roof, Stay sewn. The waterproof layer is divided into several squares.

- Q:Do you need a cushion on the ground floor?

- In addition to wood also buy wooden side, used as the main beam, beam and pillars. The ground is also recommended to raise, raise the place also to beam and pillars The number of boards to be based on your design to determine the ground practice, roof practices will affect the number of wood

- Q:When the cushion is used, the thickness of the protective layer is not less than ()

- Not on the roof: the general waterproof layer above can be used 15 ~ 25mm cement mortar protection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Woven Tarpaulin with Sun-Resistant with Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products