PE Strip Tarpaulin

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 20 Container Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

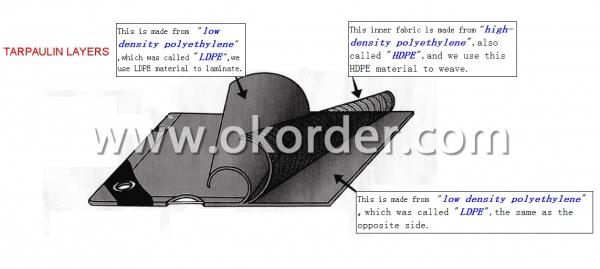

PE strip tarpaulin, made by high density polyethylene fabric and low density polyethylene coating, is characterized by good tensile strength,waterproof, dustproof etc. is an ideal and economical covering material in different fields, such as industry filed, agricultural feild etc. It's also widely used as the temporary shelter/ tents in some typhoon and earthquake stricken area.

Detailed information of PE strip tarpaulin:

|

Size |

Width:up to 100", after welded, up to16m |

|

Length: 100m/roll or as per other requirements | |

|

Color |

Customized |

|

Density |

60-300gsm |

|

Weave mesh |

5*6,7*7,8*8,10*10,12*12,14*14 |

Feature of PE strip tarpaulin

1. Tear resistant

2. Water proof

3. Mildew proof, anti-aging

4. UV blocker/stablized(optional)

Package of PE strip tarpaulin

Packed on Paper tubes;

Wraped in the same tarpaulin sheet as inner product.

Tarpaulin rolls or sheets was put into 1x20'or 1x40'HQ container.

Application of PE strip tarpaulin:

Truck/car/boat cover, cargo storage, contruction site cover, equipments covers, swimming pool cover ,container covering marine use, landscaping use, etc

Remark:Customized product is available.

- Q:What is the waterproof layer and the waterproof cushion in the tile roof?

- In the tile roof, to wait for the waterproof layer after the dry layer, or prone to the phenomenon of wall off. Waterproof layer set and standard construction methods: to be painted 2 to 3 times, or should be added fiberglass cloth, and each brushing the thickness of the cured material shall not be less than 1 mm, and should be completely dry (about 5-8 Hour) and then the next construction. After brushing, but also in the paint waterproof layer to do a mortar protective layer, and finally paste the tile.

- Q:Is foam concrete suitable for use as a cushion?

- And then through the foaming machine pumping system for cast-in-place construction or mold forming, the formation of natural conservation with a large number of closed pores of the new lightweight insulation materials.

- Q:Is it possible to make a waterproof layer

- 3, waterproof layer set and standard construction methods: to be painted 2 to 3 times, or should be added fiberglass cloth, and each brushing the thickness of the cured material shall not be less than 1 mm, and should be completely dry (about 5 -8 hours) and then the next construction. After brushing, but also in the paint waterproof layer to do a mortar protective layer, and finally paste the tile.

- Q:Foam concrete for the roof cushion generally do much bulk ah

- in recent years, the density of 160kg / m3 ultra-light foam concrete is also used in construction projects.

- Q:Basement floor mattress dry to what degree can do coil waterproof?

- Third, the membrane waterproof in the construction should first do the basement floor of the waterproof, and then the membrane along the basement floor continuous paste to the outer surface of the wall. Basement floor waterproofing first in the foundation pouring C10 concrete cushion, the thickness of about 100mm. And then paste the membrane, and then in the coil to wear 20 thick 1: 3 cement mortar, and finally pouring reinforced concrete floor. The outer surface of the wall first wip 20mm thick 1: 3 cement mortar, cold base oil, and then paste the membrane, the membrane should be stitched paste, adjacent coil lap width of not less than 100mm. The top of the coil should be higher than the maximum water level of about 500mm, the outer side of the brick wall.

- Q:What is the relationship between the cushion and the ring beam?

- Ring beam is reinforced concrete. Is to increase the overall wall and overall stiffness, improve the side resistance performance, according to the earthquake or masonry specifications set. There may be in the ground wall, there may be in the underground wall.

- Q:The top floor made waterproof playing cushion layer of how to do

- 3. The first layer to do a flexible waterproof, try the valve Bai fat together with the full bricks that are roof-specific anti-aging waterproof coating.

- Q:Do you need a cushion on the ground floor?

- As well as the time to build a wooden building with concrete pier, from the ground or contact the ground to do a good job preserving.

- Q:When the cushion is used, the thickness of the protective layer is not less than ()

- Basement roof: non-load protection layer generally use C20 fine stone concrete or reinforced concrete, the thickness of 50 ~ 80mm. The road, driving the protective layer is determined by design.

- Q:The roof cushion is waterproof on the slope roof

- and the formation of the ice dam will lead to roof water, water will find the path into the house.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2003 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | Mid East,Europe,The America,Southeast Asia Africa ,Oceania ,Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

PE Strip Tarpaulin

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 20 Container Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords