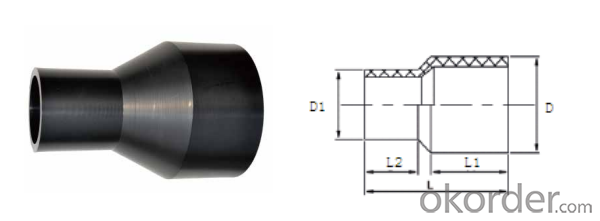

PE Reducer Plactic Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Reducer Pipe Fittings for Pipeline System

Pressure grade:

PN≤1.6MPa when DN<400MM

PN≤1.0MPa when DN≥400MM

Size: DN125MM-DN630MM

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:Are plastic pipe fittings resistant to water hammer?

- Yes, plastic pipe fittings are generally resistant to water hammer due to their flexible and durable nature, which helps absorb the shockwaves caused by sudden changes in water flow.

- Q:How do plastic pipe fittings compare to metal fittings?

- Plastic pipe fittings are generally lighter, more cost-effective, and easier to install compared to metal fittings. They are resistant to corrosion and chemical damage, making them suitable for various applications. However, metal fittings are generally stronger and more durable, offering greater longevity and withstanding higher pressures. The choice between plastic and metal fittings depends on specific needs, such as the type of pipe, application, budget, and desired lifespan.

- Q:PSP plastic steel composite pressure pipe has several ways of connecting

- (3) it can be installed without any anti-corrosion treatment, thus saving the project cost.(4) the complete steel pipe layer is the main pressure bearing layer of the pipe body, so the bearing capacity of the pipe is not affected by the change of the plastic layer.(5) it has excellent sealing performance, anti stripping, easy to install, and also has the adaptive ability of various deformation of pipes and pipelines.

- Q:How do you remove a plastic pipe fitting?

- To remove a plastic pipe fitting, you can try using a heat gun or a hairdryer to warm up the fitting, making it more pliable. Then, you can gently twist and pull the fitting while applying some force to detach it from the pipe. If this doesn't work, you can use a fitting removal tool or a pair of pliers to grip the fitting tightly and twist it counterclockwise until it loosens and can be pulled off.

- Q:Are plastic pipe fittings resistant to thermal contraction?

- Yes, plastic pipe fittings are generally resistant to thermal contraction.

- Q:Can plastic pipe fittings be used for CO2 capture systems?

- Yes, plastic pipe fittings can be used for CO2 capture systems. Plastic fittings, such as PVC or polypropylene, are commonly used in various industrial applications including CO2 capture systems. They offer several advantages such as corrosion resistance, cost-effectiveness, and ease of installation. However, it is essential to ensure that the specific plastic material and fittings chosen can withstand the pressure, temperature, and other specific requirements of the CO2 capture system.

- Q:Can plastic pipe fittings be used for underground installations?

- Yes, plastic pipe fittings can be used for underground installations. Plastic pipe fittings, such as those made from PVC or polyethylene, are commonly used in underground applications due to their durability and resistance to corrosion. These fittings are designed to withstand the soil and environmental conditions typically encountered underground, making them a suitable choice for various underground installations like water supply systems, drainage systems, and irrigation systems.

- Q:How do plastic pipe fittings handle seismic activity?

- Plastic pipe fittings are designed to withstand seismic activity by being flexible and resistant to vibrations. The material used in plastic fittings, such as PVC or HDPE, allows them to absorb shocks and movements caused by earthquakes. These fittings can flex and bend without breaking, reducing the risk of pipe damage or leakage during seismic events. Additionally, plastic fittings are lightweight and easy to install, making them a popular choice in earthquake-prone areas.

- Q:As long as the quality of plastic pipe is good Can the problem of plastic pipe connection be neglected?

- Only the performance of the pipe itself is not enough, the connection of plastic pipe is the largest local problem in pipeline system, especially the use of pipe connections, such as hot melt connection, no welding operation in accordance with the construction standard, extremely easy to cause hidden troubles due to leakage. General plastic pipe product standards are required to test the applicability of the system, can be selected according to the actual situation of the project inspection. Communicate further if you have any questions.

- Q:Are plastic pipe fittings environmentally friendly?

- Plastic pipe fittings are generally considered to be more environmentally friendly compared to other materials such as metal or concrete. They are lightweight, durable, and have a longer lifespan, reducing the need for frequent replacements. Additionally, plastic pipe fittings are resistant to corrosion and chemical damage, which can decrease the likelihood of leaks and subsequent water wastage. However, it is important to note that plastic pipe fittings can still have negative environmental impacts if not properly disposed of or recycled.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Reducer Plactic Pipe Fittings for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords