PE Prepainted Aluminium Coil for Gutters

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of PE Prepainted Aluminium Coil for Gutters

PE Prepainted Aluminium Coil for Outdoor Gutters is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PE Prepainted Aluminium Coil for Gutters

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of PE Prepainted Aluminium Coil for Gutters

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PE Prepainted Aluminium Coil for Gutters

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PE Prepainted Aluminium Coil for Gutters

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

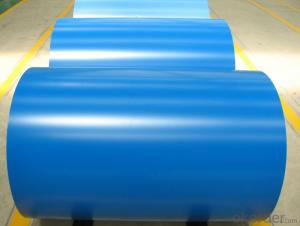

6. Image of PE Prepainted Aluminium Coil for Gutters

7. Package and shipping of PE Prepainted Aluminium Coil for Gutters

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be used in automotive body panels?

- Yes, aluminum coils can be used in automotive body panels. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for automotive applications. The use of aluminum coils in body panels offers several advantages, including improved fuel efficiency due to the reduced weight of the vehicle, better handling and maneuverability, and enhanced durability. Additionally, aluminum is highly recyclable, making it an environmentally friendly option for automotive manufacturing. Many automakers have already started incorporating aluminum coils in their vehicles, and this trend is expected to continue as the industry strives for lighter and more sustainable vehicles.

- Q:Never put oil in the water. Oil keeps the pasta from absorbing the sauce. Also add a little of the pasta water 3 Tbs. to the sauce. This helps sauce to adhere to pasta. The best remedy for pasta sticking. Use an aluminum stock pot. (tall pan). I don't know why but this works. I have using this stock pot for pasta for 40 years. I've tried stainless, non-stick, etc. they all stick. Except for the Aluminum.1 lb. of pasta, 4 qts. of water. 1Tbs. saltTurn burner to high,keep it therebring to boil then boil for 3 minutes, add 1 TBS salt, add pasta. Stir slowly 2 minutes, until the water boils. Cook tender enough for a fork to cut through but still a little firm

- Cooking in aluminum is not good! It leaches into the foods, you absorb it and it causes brain damage similar to parkinsons. I don't own any aluminum and I never will.

- Q:How many atoms are there in a piece of aluminum foil, 7.3 inches in length and 12.0 inches in width, and 0.141 mm thick? According to this problem, aluminum foil is a flat-rolled product, rectangular in cross section, of thickness from 0.006(0.15mm) to 0.00025(0.006mm). The density of Al is 2.699 g/cm3.

- the nice and cozy button is Avogadro' sort that's 6.0226 x 10^23 atoms consistent with mole So if the cost of the Al roll is $2.fifty two for one lb Then proceed as follows: a million lb = 454 gms At Wt Al = 26.ninety 8 gms consistent with mole Moles of Al in a million lb = 454/26.ninety 8 = sixteen.80 two moles sort of atms of Al = sixteen.80 two x 6.0226 x 10^23 = a million.013 x 10^25 cost consistent with atom = $2.fifty two / a million.013 x 10^25 = $2.2847 x 10^-25 consistent with atom or 0.0000000000000000000000228 cents consistent with atom. BTW, you probably did no longer finished specify the situation - how thick is teh Al foil? In any journey Al atoms are enormously inexpensive. desire this helps

- Q:I am planning on calling an electrician before we move in. I was just wondering about some ballpark estimates to rewire a home with aluminum wiring (appx. 1900 sq feet).

- Sarah: I can't answer your question, but I plead with you and your husband to not purchase a house with that wiring if you value your life. In my locale there have been so many homes that have burned down causing loss of life as a result of aluminum wiring. Unless you COMPLETELY exchange all the wiring for copper wire, you will never FEEL SAFE. Rely on history. It is far greater to be SAFE NOW than to be SORRY LATER. NO house is worth that RISK!

- Q:Can aluminum coils be used in high-radiation environments?

- Yes, aluminum coils can be used in high-radiation environments. Aluminum has good radiation resistance and can withstand high levels of radiation without significant degradation or damage. It is commonly used in applications such as nuclear power plants and aerospace industries, where radiation exposure is a concern.

- Q:What is the maximum width-to-thickness ratio for aluminum coils?

- The maximum width-to-thickness ratio for aluminum coils is influenced by various factors, including the specific alloy, temper, and intended application. Industries like construction, automotive, and packaging commonly employ aluminum coils, which may necessitate different width-to-thickness ratios. Typically, the width-to-thickness ratio for aluminum coils ranges from 100:1 to 200:1. However, it is crucial to recognize that this range can fluctuate depending on the specific alloy and temper. Thicker coils generally possess a lower width-to-thickness ratio, while thinner coils may have a higher ratio. High-strength alloys, particularly those utilized in aerospace applications, typically exhibit lower width-to-thickness ratios due to their heightened strength requirements. Conversely, coils used in less demanding applications might have higher width-to-thickness ratios. To determine the appropriate width-to-thickness ratio for a specific aluminum coil, it is essential to consult relevant industry standards, specifications, or manufacturer guidelines. These guidelines take into account the intended use, mechanical properties, and performance requirements, ensuring that the coil is suitable for its intended application while maintaining structural integrity and functionality.

- Q:How are aluminum coils used in the production of musical instruments?

- Aluminum coils are commonly used in the production of musical instruments, particularly in wind instruments like saxophones and trumpets. These coils are shaped into a specific design and attached to the instrument to create the desired sound. The aluminum material allows for a lightweight and durable construction, enhancing the instrument's playability and resonance.

- Q:When aluminum metal is heated with an element from group VIA of the periodic table, an ionic compound forms. When the experiment is performed with an unknown croup VIA element, the product is 18.56% Al by mass. What is the formula of the compound and what is its name?

- Al2Se3 aluminum selenide

- Q:Can aluminum coils be used in the production of solar reflectors?

- Yes, aluminum coils can be used in the production of solar reflectors. Aluminum is a commonly used material in the manufacturing of solar reflectors due to its high reflectivity and durability. The coils can be processed and shaped into the desired form for the reflector, allowing for efficient reflection of sunlight onto the solar panels. Additionally, aluminum is lightweight, making it easier to handle and install in solar reflector systems.

- Q:Can aluminum coils be used in the production of aluminum sunshades?

- Aluminum sunshades can indeed incorporate aluminum coils. In the manufacturing process of these sunshades, aluminum coils serve as the initial material. These coils are crafted from top-notch aluminum, renowned for its lightweight and resilient properties. They are subsequently formed and molded into the desired shape for the sunshade, whether it is slats, louvers, or a solid panel. The corrosion resistance and ability to withstand diverse weather conditions are among the reasons why aluminum is a favored choice for sunshades. It is worth noting that aluminum is easily recyclable, rendering it an environmentally friendly material for sunshade production. All in all, aluminum coils are indispensable elements in the creation of aluminum sunshades, contributing to their strength, durability, and aesthetic allure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Prepainted Aluminium Coil for Gutters

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords