PE Geomembrane Liners with the Biggest liner factory in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geomembrane

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

Geomembrane specifications

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

HDPE geomenbrane Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

HDPE Geomembrane Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

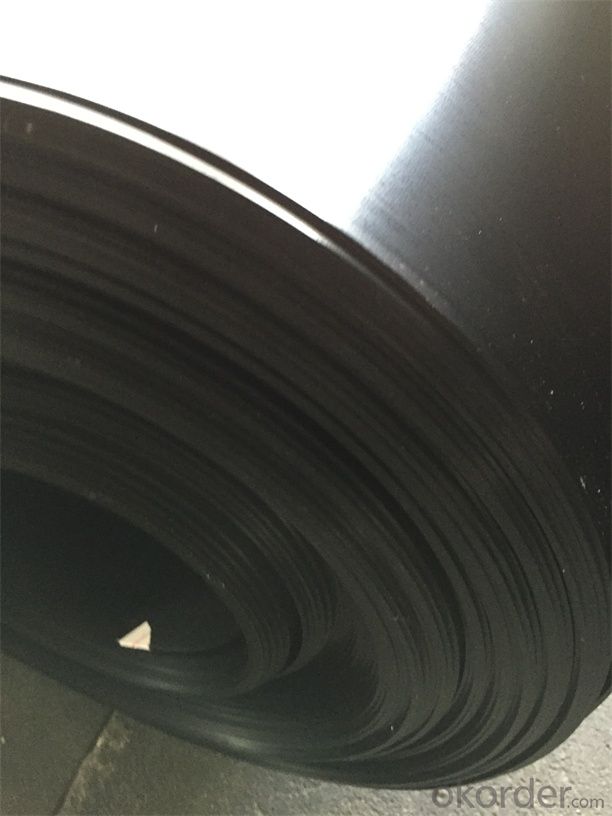

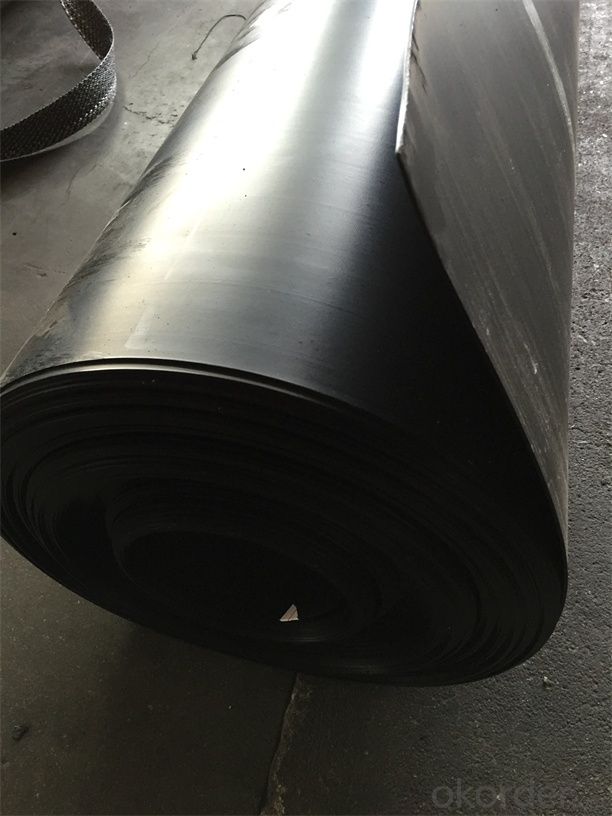

Gemembrane Show:

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:What types of work does geomembrane welding belong to?

- Excavator

- Q:which one is good , Matte stick membrane or high permeability stick membrane

- High permeable membrane: Strong light transmission. But when touching screen the operation is blocked, poor hand?feeling. Fingerprint, oil pollution is obvious, it is recommended to take lens cleaner. Composite membrane: when touching the screen the operation is smooth, good hand?feeling, and it can hidden fingerprints and oil pollution at a certain degree. Matte film: when touching the screen the hand?feeling is the best, but the light transmission is not ideal. hand?feeling difference: The high permeability film is a smooth plane, so the hand?feeling is usually similar to the screen. But in fact, due to the difference of the packaging film substrate, even if it is the same as high permeable membrane, different materials have a lot of difference in hand?feeling. A lot of people think that the touch surface must be very rough surface, in fact, the film is only a little bit resistance than high permeable membrane. Feeling a more straightforward, operation is not clear-cut. The reason why most users choose the matte membrane is because it "has a little resistance" feel, and this is another kind of operation experience. Overview: The high permeable packaging film has the advantage of high transmittance, the surface of the packaging film is smooth, and the hand?feeling is fluent. But it is easy to leave fingerprints, and once stained with fingerprints it is difficult to clean up. matte packaging film, as the name, the surface has a matte texture, the advantage is effective to against fingerprint, and easy to clean up. it has a slight impact on the display effect, unique hand?feeling, giving users a different operating experience. specifically which kind is good. it depends on personal needs.

- Q:What is the carbon resister

- The carbon resister is made by heating polymerization, which uses an organic adhesive to make a suspension liquid by the carbon ink, graphite and the filling material and then be coated on the insulating substrate. Gaseous hydrocarbons are decomposed in high temperature and vacuum, the carbon is deposited on a ceramic rod or a ceramic tube to form a layer of crystalline carbon film.

- Q:what's the function of paving composite geo-membrane in fishpond?

- seepage-proof and water conservation

- Q:How do geomembranes contribute to erosion control in coastal and shoreline protection?

- Geomembranes contribute to erosion control in coastal and shoreline protection by acting as barriers that prevent the erosion of soil and the loss of sediment. They are installed along the shoreline to provide a protective layer that minimizes the impact of waves, tides, and currents. These impermeable membranes help to stabilize the shoreline by reducing the erosion caused by the forces of nature, thereby safeguarding coastal areas and mitigating the negative effects of erosion.

- Q:Can geomembranes be used in reservoir lining?

- Yes, geomembranes can be used in reservoir lining.

- Q:What is the typical thickness of a geomembrane in a pond liner application?

- The typical thickness of a geomembrane in a pond liner application can vary depending on factors such as the size and type of the pond, as well as the specific requirements for containment and durability. However, in general, geomembranes used in pond liner applications are often between 0.5 to 2 millimeters thick.

- Q:What exactly is the geomembrane? What are the applications?

- At the same time, alkali and salt corrosion, long service life; and non-woven fabric is also a kind of high-molecule short fiber chemical material. Geomembrane construction site its main mechanism is to use imperviousness of plastic film to cut off earth dam leakage passage, not only increases the tensile strength and anti-puncture ability of plastic film. They have good corrosion resistance to bacteria and chemical action, which is conducive to the stability of composite geomembrane and protective layer, with high tensile strength and extensibility, bearing the hydraulic?pressure and adapting to dam deformation with its large tensile strength and ductility, increasing the friction coefficient of the contact surface. And due to the roughness of the non-woven surface, geomembrane construction site its main mechanism is to use imperviousness of plastic film to cut off earth dam leakage passage; and non-woven fabric is also a kind of high-molecule short fiber chemical material, bearing the hydraulic?pressure and adapting to dam deformation with its large tensile strength and ductility, through needle punching or hot sticking forming, it is combined with plastic film, used in the dark place, not afraid of acid

- Q:Is it safty to use the infrared electrothermal?film floor heating?

- Product itself has no problem, but now as the country does not have the construction atlas, it lacks an authoritative guidance to the construction, the construction?technology of construction units is not different, some small construction team can not grasp the key working procedure, it will appear tripping after make it

- Q:Concrete and reinforced concrete construction program

- (1) template design, process design based on fair-faced concrete wall height of 13m, the length of 34.6m, a thickness of 0.5m, the design of the wall cicada seam topstitching requirements, using the wall template with a thickness of 12 mm, 1220 × 2440mm of Plywood covered were assembled, smooth bamboo has high strength, good toughness, smooth surface, wide-format, less patchwork, easy mold release characteristics. (2) On the basis of template installation concrete pouring is completed, the base elevation of the top of the concrete to be strictly controlled to ensure that the level on the wall template. Control template verticality is the key step, each template before fixing must be strictly controlled. Template vertical transport of scaffolding on the use of hand hoist, horizontal transport using manual handling. Templates in the handling process to the use of surface protection, to ensure that will not be damaged. To ensure that does not leak between the template and the template pulp, cracks in the template posted double-sided adhesive to ensure continuous tightly between two templates. Before template installation to wipe clean the surface evenly coated with a release agent. (3) the template of bolt and bolt arrangement using reinforced through the wall sleeve to add plug positioned to ensure that the position of the perforations through the wall tight to prevent leakage of plasma, wall bushing strength sufficient to locate the template spacing, resistance to new concrete pouring liquid pressure without generating the template gap is too large, plasma leakage phenomenon.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE Geomembrane Liners with the Biggest liner factory in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords