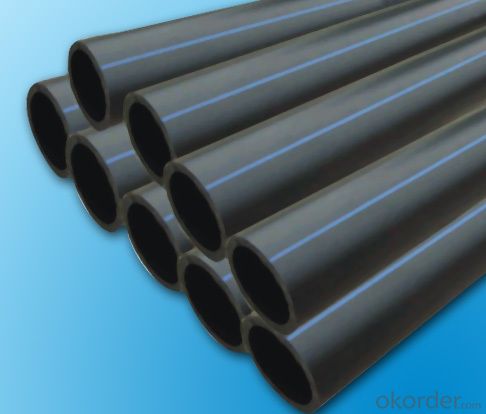

PE gas pipe manufacture B 311

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. PE gas pipe manufacture (GB/T 15558-2003)

Quick Details

· Place of Origin: China (Mainland)

· Material: PE

· Specification: 20-630mm

· Length: 5.9/11.8M

· Standard: GB/T15558-2003

Packaging & Delivery

Packaging Details: | bundle or as your required |

Delivery Detail: | within 15 days after downpayment |

Specifications

PE gas pipe manufacture (GB/T 15558-2003)

1. OD:20-630mm

2. Standard: GB/T15558-2003

3. Quality with competitive price

PE GAS PIPE

Material: PE 100

Specification: 20mm-630mm

Length: 5.8m 11.8m per length

Thickness: 2.3mm~57.3mm

Standard: GB/15558, ISO4437

Color: black, yellow or black with yellow stripe or others

Feature:

**Long service life: PE pipe can be used safety for more than 50 years

**Excellent resistance to corrosion capability: It can endure the erosion of various kinds of chemical media, no electrochemical corrosion.

**Excellent transportation capability: the inner side of the PE pipe is smooth and has litter abrasion and resistance. The absolute roughness k=1.01mm and “k” will not change with time.

**Reliable joint capability: the intensity of the welded joint of PE pipes is above the pipe itself. The interface will not disconnect because of the moving of soil or the live load.

**Reliable safety capability: PE pipe has strong capability of anti-cracking and is not prone to crack.

**Better resistance to concussion capability: PE pipe possesses high toughness and can endure strong impact. Pressure of heavy things will not cause the pipe to break.

**Strong toughness: PE pipe is a kind of pipe that possesses high toughness whose breaking elongation rate generally exceeds 500% and has strong ability to adapt to the uneven settlement of the pipe bending.

**Excellent flexibility: PE pipe can be easy to change in accordance with the construction requirements. Small-diameter pipe is available to be supplied in coils.

**Installation cost lower: light weight, easy handling and installing, simple welding technique and exemption of being embalmed result in low construction cost.

Application:

gas distribution, environmental protection, and chemical industry etc.

2. PE PIPE MANUFACTURE (ISO 4427)

Quick Details

· Type: Other Plastic Building Materials

· Place of Origin: China (Mainland)

· Size: 16-1600mm

· Color: Black, blue

Packaging & Delivery

Packaging Details: | plastic bags or as your request |

Delivery Detail: | Within 25 days after receiving the payment |

Specifications

PE PIPE MANUFACTURE (ISO 4427)

A. Material: High quality PE80 or PE100

B. Diameter: 16 to 1600mm

C. Pressure:0.6-1.6Mpa

PE PIPE MANUFACTURE (ISO 4427)

Features:

**Sizes: 16 to 1600mm

**Pressure Rating: 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, 1.6MPa

**Colors: blue, black or other colors on request

**Connection: socket fusion joint, butt fusion joint, electro fusion joint, flanged joint

**Standard: GB/T 13663, ISO 4427

**Certification: ISO9001, ISO14001

**Packaging: coils in plastic bag or as your request

Advantages:

**Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

**Corrosion Resistant: resist chemical matters or electron chemical corrosion

**Lower Installation Costs: light weight and ease of installation can reduce installation costs by

as much as 50% over metal piping system

**Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume

than metal pipe

**Longevity: more than 50 years under proper use

**Recycled and Environment-friendly

Application

water pipe network system, industrial liquids transportation, Agricultural irrigation pipe and sewage treatment

- Q:Method for connecting glass tube and rubber tube

- Wet the connection with water first. Just turn it clockwise

- Q:How to make sure the rubber hose will not be worn off?

- This depends on experience, not carefully measured out of the value is also a great error

- Q:What do you mean by "DN" on hydraulic hose?

- DN stands for nominal diameter. The standard diameter after standardization, the midpoint between the inner diameter and the outer diameter, in units mm.

- Q:Why should the water stop strip be joined by heat instead of superposition?

- Thermal connection is the safest and most reliable method of joint treatment, but it has certain requirements for technology.

- Q:What material is used in the gas pipeline to reduce the wastage?

- The inner layer and the outer layer plastic tube is a kind of special polyethylene material, non-toxic environmental protection and quality of light, the nature "is very suitable for application can take temporary setbacks" in the home decoration. But as aluminum pipe of indoor gas pipe, can withstand the pressure of work, but also because the pipeline can be extended for a long distance, need the joint is less, so the gas permeability is almost close to zero. Using aluminum pipe owners as household gas transportation route is safe and reliable, but be careful to avoid buy inferior aluminum-plastic, because the market inferior aluminum pipe by the collision, easy bending, deformation, or even rupture, threatening the safety of life and property owners.

- Q:The small hose attached to the grease gun is coarse or fine at the joint

- The joint on the grease gun is made of fine thread. The characteristics of fine thread are small pitch, small spiral angle, good self-locking, and not easy to loosen.

- Q:How can the rubber pipe leaking from the cold water inlet of the electric water heater do?

- Estimation is inside the pipe aging cracking due to Water Leakage, no maintenance necessary, unless it is a joint sealing ring in aging can replace the sealing ring of new or with rubber or other flexible items I cut a replacement.

- Q:What does rubber soft joint "KDTF" mean?

- KDFT flexible single ball rubber joints of rubber joints, rubber flexible connector is made of fabric reinforced rubber parts and flat joint, loose metal flange or threaded pipe flange, joint for pipe vibration noise reduction, displacement compensation.

- Q:Plastic coated metal hose flexible conduit joint what treatment

- Joints are generally zinc alloy material, the surface can be plated hard chromium treatment, plastic pipes and many types of joints can match

- Q:What are the methods of sterilizing rubber hoses and Perspex?

- Plexiglass products, we are placed on super clean bench, UV irradiation above 30min. Sometimes it takes time to wipe with 60% alcohol cotton ball.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE gas pipe manufacture B 311

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords