PE 500*750 Jaw Crusher-Primary Crushing Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

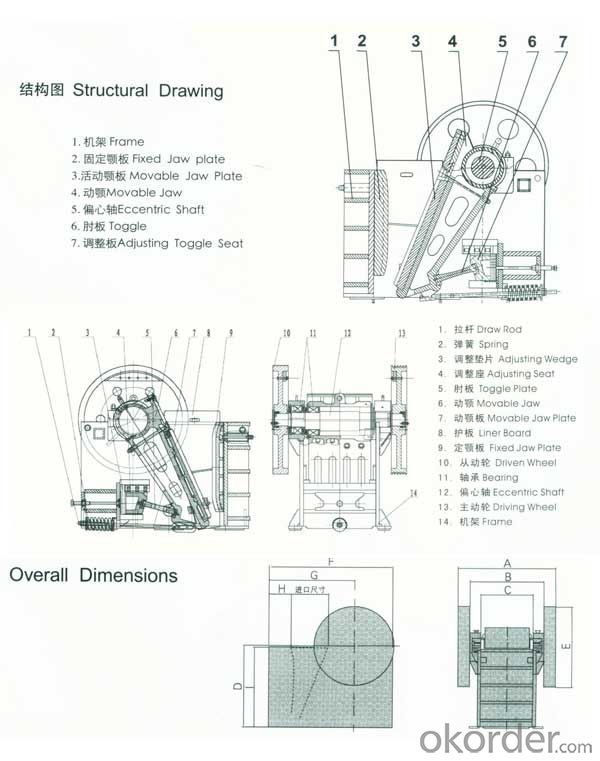

Jaw Crusher Introduction :

Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA. Jaw Crusher is of high crushing ratio, larger capacity, well-distributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc. It is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

Features of Jaw Crusher:

1,High crushing ratio, well-distributed final product size.

2,Discharge opening of the jaw crusher is adjustable reliably within a wide range through the stuffing of shim, thus it is capable to meet various requirements of customers

3,lubrication system of it is safe and reliable, which boasts an easy and convenient maintenance

4,simple structure, reliable performance, low maintenance cost

5,little dust and low noise

Parameter of Jaw Crusher

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging Range size(mm) | Capacity (m3/h) | Motor power(kw) | Weight (t) |

| PE-250*400 | 250*400 | 210 | 20-60 | 3-13 | 15 | 2.8 |

| PE-400*600 | 400*600 | 340 | 40-100 | 10-35 | 30 | 6.5 |

| PE-500*750 | 500*750 | 425 | 50-100 | 25-60 | 55 | 10.6 |

| PE-600*900 | 600*900 | 500 | 65-180 | 30-85 | 55-75 | 15.5 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 72-150 | 90-110 | 28 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 85-143 | 90-110 | 30 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 145-235 | 90-110 | 30.5 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 170-250 | 90-110 | 31 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 100-240 | 110-132 | 49 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 190-275 | 110-132 | 51 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 250-500 | 160 | 100.9 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 5-16 | 15 | 3.5 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 8-22 | 22 | 4.9 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 10-32 | 30-37 | 6.5 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 13-38 | 37 | 7.7 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 10-65 | 75 | 11 |

Reference Photos

- Q:what year was the first hydraulic car crusher invented?

- Car Crusher Machine

- Q:When you do skull crushers are your elbows supposed to hurt afterwards?

- That's the problem with tricep isolation exercises. They can be tough on the elbow joint. Some folks can tolerate them without any apparent trouble, but not everyone and you don't want to mess up your elbows. I've never had trouble with the lying tricep press (skullcrusher)but tricep pushdowns are murder on my elbows. I suggest you experiment with other tricep moves. Dips are great. If seated or standing overhead tricep presses also cause you discomfort, try using one solid dumbbell held with both hands and let your elbows point out to the sides instead of forward. Close grip bench presses are another good tricep movement. Protect your elbows. You'll need them for a long time.

- Q:Who has the best and worst nickname in boxing??

- Worst : The Greatest First of all what kind of nickname is this?The only reason so many people think he is/was the greatest is because of the psychological phenomenon that when you say a lie enough times, it becomes the truth. The Black Rhino, White Buffalo, Brown Bomber are pretty bad too. I just think that making your nickname racial is tasteless. I don't really like The Golden Boy because at some point DLH needs to grow up. How long until it changes to The Olden Man? Same thing goes for Pretty Boy Floyd Mayweather. Buster is aweful. Who wants to be a buster? Sugar is a great nickname, but should only be used on Hall of Fame boxers. Iron is a good one because its so original. The Executioner is good too. The all-time greatest nickname has got to be Butterbean Who doesn't love the name Butterbean? That name is so good that virtually nobody knows that his real name is Eric Esch.

- Q:Does anyone know what it is called? The thing that a pharmacist used to crush pills, the old fashion way. It is like a thick glass bowl with a glass thing thats used to stir and crush pills?

- a mortar and pestle.

- Q:what equipment do you need to start a small winery?

- Crusher, press, vats. Read the books Vines into Wines and Grapes into Wine to get an idea.

- Q:anyone ever heard of Advantage alarm systems? I am wondering if it is better than ADT.

- Good keep going.Havent done skulls in a long time.Last time i did 80s of 8 reps i think.Now i do close grip bench for skulls works better for me.185 of 5s as of last time.

- Q:A match that will never take place.But I am curious of the responses.Rick and Scott Steiner vs the Crusher and the Bruiser

- giant haystacks i think?

- Q:I own a 2007 mazda 3. I need to replace my lock actuator in the driver side door. I have a key less remote access. Does anyone know the part number for the lock assembly actuator that I need?

- This is a long article and no pix the descriptions good look on the net ++ How to Make a Cat Cage Out of PVC Pipe ++of the be sure that you weave the seams of the enclosure wire screen on the outside of the cage so, kitty doesn't get snagged this is a good idea and the pvc pipe will not rot and should be easy to work with galvanized screen in a 1/2 inch open squares pattern will last a long time and plastic zip-ties are easy to work with.. .. enjoy just make a diagram of what you want lay out what is needed in the pipe and figure the screen cloth when done with the frame a good PVC pipe cutter is worth that expense to make cutting precise and easy daub the glue and twist the PVC into the fittings and corners - some hardware stores have better selections of the fittings you need assemble PVC frame parts fittings and then you can start cutting the frame .

- Q:i am a girl(i know i spelled it wrong)

- AKG and Sennheiser win HANDS DOWN. Skullcandy breaks WAY too easily and its sound is RUBBISH. Other equally reputable manufacturers besides AKG include Sennheiser, Shure, Grado, Denon, Bowers Wilkins, Bang Olufsen, Etymotic, Beyerdynamic and Audio-Technica.

- Q:I have a 2003 impala. It has keyless entry but when I read through the handbook i found out only certain ones came with the alarm feature. The book told me how to check and see what I have and after I looked through I discovered it doesnt have the alarm feature. (what a waste to have keyless entry without an alarm) But it uses the same kind of remote that a car with the alarm feature would use. So my question is, Is there anyway to have the alarm feature added without buying a completely different keyless entry system with its own alarm? It would be more convient to have an aalrm added to the system I already have. (they would also have to unistall what I already have which would cost alot) Thanks in advance!!

- Fire extinguishers are meant to be checked by a professional extinguisher company after each use, some are one time use and can't be refilled. Extinguishers must be emptied, cleaned refilled with new chemical and pressurized so that they can sit for a long time and then you are certain that they will perform when called upon. You wouldn't like it if you are confronting a fire and the extinguisher doesn't work. Get it checked, or get a new one. Your life and the lives of the ones you love depend on it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE 500*750 Jaw Crusher-Primary Crushing Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords