PDC Thrust Bearing used in downhole dynamic drilling tools

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.PDC thrust bearing is widely used in downhole dynamic drilling tools, it is with high hardness and longer life charateristics. It can be in operation at super high temperature (currently the highest temperature is 233℃)and it can hold higher axial load. One pair PDC thrust bearing includes upper ring and bottom ring,one piece PDC thrust bearing includes two part: tungsten carbide ring and PDC compact.PDC material friction coefficient is very low so that it can not be affected by chemical material.

2.PDC thrust bearing is made with standard brazing technology, its compact surface hardness is very high, the contact surface flatness of PDC compact is very low and difficult to manufacture. Few factories in China could overcome this problem.

3.With many times improvement Research and development, we use more advanced welding and grinding technology, has overcome the flatness problem of PDC compact contact surface, make the contact surface flatness less than 0.02mm so that strongly improved PDC thrust bearing service life. Our technology for manufacturing PDC thrust bearing has reached the international advanced level in the industry.

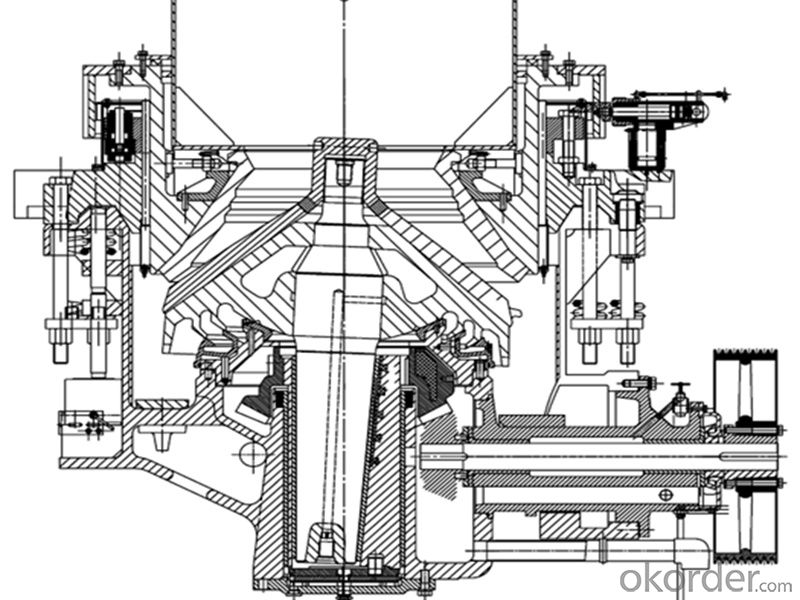

4.Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Is there any difference between plain bearings and other bearings?

- The biggest difference between the sliding bearings is linear motion, and the other bearings do circular motion.

- Q:I feel different from other factories, ah, there is no pungent smell!

- You go to Harbin axis Ji'nan company to ask, they are the factory's direct center, can solve your problem

- Q:Since what year did NSK begin to provide bearings and other related components for the aircraft industry?

- Look! How strong is our motherland! But we can't be content with that.

- Q:Yoyo how can I wash the bearings without gas?. What other materials can I use?

- Thinner, acetone, chloroform, banana water, kerosene.

- Q:why the inner ring of a knock on the broken, and other small manufacturers desperately not broken, is the material problems or other reasons? The hardness is about the same. LYC62 another 63. How can this be explained? Seek expert advice!

- You may have this bearingImitationThe hardness is not too high,High imitation is the quality of the bad ah!May not be annealed, hard, dryPay attention later

- Q:22318CA are there any other bearings that can be used instead?

- If you think the 22318 speed is not high enough, you can get a 2318 instead. But! 2318 of the load is not 22318 high, must confirm the load before changing

- Q:where can I buy other GPS drilling accessories? I have some GPS rigs.

- With so many rigs, you can buy it directly from Wuhan Jintai Geological Engineering Machinery Co., ltd.... They have all rig accessories, very, very complete. You can call them 400

- Q:In bearings, why are the flanges connecting the upper and lower cases higher than those of the other bearings?

- If it is understood as the reducer, the upper and lower box connecting the flange (bearing box outside the prominent part), the reason is to prevent the bearings in operation, gear and box friction, damage box, reduce gear life.

- Q:A one-way bearing keyway hole can connect other parts of the shaft, driven by cylindrical rotation? How much speed can I expect?

- You are not allowed to say this, with thick shaft, what types of bearings, preferably a drawing can be discussed, or that is not clear

- Q:In addition there is no other original bearing high speed bearing deposit in 50 seconds or more for the name?

- If you're looking for speed, just like speed shoes.I suggest you go to 66club, take a look at all over the country, a forum for yo yo lovers, is currently more influential domestic university skating hobby league.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PDC Thrust Bearing used in downhole dynamic drilling tools

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords