PC Steel Bar Complete Induction Heating Equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 25 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application Scope

Steel Bar for Pre-stressed Concrete

Production and processing of PC steel bar (Steel Bar for Pre-stressed Concrete), quenching and tempering heat treatment of metal wire.

Function Structure

PC steel bar production line is complete automatic control: several sets of medium frequency/super audio frequency power supply accomplish pre heating, heating, quenching and tempering of steel bar online. Realize synchronization control of production line by several sets of inverters driving the mechanism.

There are totally four sets of heating power supply of PC steel bar production line, the power and frequency of which are designed to be: 600kW/8kHz, 200kW/30kHz, 200kW/50kHz, 300kW/8kHz. The power supply adopts parallel IGBT induction heating power supply. It is just because of online heating that there’re strict requirements concerning working status and synchronization control of the power supply.

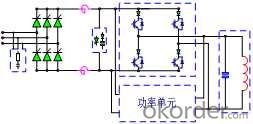

The parallel IGBT induction heating power supply adopts AC-DC-AC variable frequency power supply structure. The rectifier of the power supply adopts 3-phase thyristor rectifying or diode and IGBT chopper mode. The inverter adopts high voltage large power IGBT module and large power fast recovery diode to form inverter power unit. The resonant tank circuit adopts parallel resonance.

The whole unit of equipment is composed of four sets of induction heating equipment, water cooling system, console, automatic control system and mechanism system.

product picture

Technical features

Excellent heating power supply design

1. Power supply cabinet and heating tank circuit adopt independent design with compact structure and small size which is convenient for site layout.

2. The heating inductor is characterized by high heating efficiency of whole line and stable heating technics by optimization design.

3.The power supply selects DC chopper mode to ensure the grid side power coefficient≥0.92 and a relative lower harmonic content.

4.Adopt CPLD full digital control system, automatic fixed angle, high precision of phase-lock and wide scope of phase-lock. Perfect protection function, reliable working and low failure rate.

5.High standard power supply electromagnetism compatibility design and closed cabinet design to meet the strict requirements at site.

Ø perfect automatic control of whole line

1. Adopt Siemens S7-300 PLC and colorful touch screen to form whole line automatic control center, which is flexible and high cost performance.

2. Having speed-power automatic matching function, which can realize full scope automatic control to different PC steel bar specification and heating speed.

3. Adopt Siemens for transducer (or specified by the user) and US Raytek for pyrometer.

4. Friendly HMI and fault diagnosis system, which is convenient for operation and maintenance.

Main Technical Parameter

| Model | AC input | Power coefficient | Rated DC voltage | Rated DC current | Frequency scope | Heating mode |

| GZP-600/8 | 3AC380V 50/60Hz | Thyristor rectifying 0.92 | 500V | 1200A | 6- 10 kHz | Pre-heating |

| IGBT chopper 0.95 | ||||||

| GCYP-200/30k | 3AC380V 50/60Hz | Thyristor rectifying 0.86 | 450V | 450A | 25~ 30 kHz | heating |

| IGBT chopper 0.95 | ||||||

| GCYP-200/50k | 3AC380V 50/60Hz | Thyristor rectifying 0.86 | 450V | 450A | 40~ 50 kHz | Quenching |

| IGBT chopper 0.95 | ||||||

| GZP-300/8 | 3AC380V 50/60Hz | Thyristor rectifying 0.92 | 500V | 600A | 6- 8 kHz | Tempering |

| IGBT chopper 0.95 |

Can be customized as per user’s grid and heat treatment technics.

Operation parameter

Steel No. 30MnSi

| Specification | 7.1 mm | 9.0mm | 10.7mm | 12.6mm |

| Linear speed | 60~110m/min | 40~100m/min | 30~90m/min | 20~60m/min |

| Quenching temperature | 860℃~960℃ | 860℃~960℃ | 860℃~960℃ | 860℃~960℃ |

| Tempering Temperature | 360℃~460℃ | 360℃~460℃ | 360℃~460℃ | 360℃~460℃ |

| Power consumption per ton | ≤375kW.h /T | ≤370kW.h /T | ≤370kW.h /T | ≤370kW.h /T |

| Tensile strength | >1420Mpa | >1420Mpa | >1420Mpa | >1420Mpa |

| Elongation | >5% | >5% | >5% | >5% |

- Q:What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q:What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q:What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q:How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q:Why does the burner of industrial furnace burn occasionally?

- The basic structure of the complete ignition system is the ignition device and flameout protection device. The ignition burner includes an ignition electrode and an igniter (equipped with some external type transformer, voltage transformer) through the above 10kV, the ignition electrode spark ignition of high voltage discharge to ignite gas column.

- Q:What are the companies in the world that are currently engaged in metallurgical furnaces?

- Basically, no industrial furnace manufacturer can do all types of stoves.Often associated with the industry is very large,so your ranking is basically meaningless.

- Q:Brief introduction to repair of industrial furnace

- Compared with other equipment, industrial furnace repair has many characteristics: more repair times, more maintenance costs, more non-standard equipment and unsafe factors.

- Q:Selection of heat preservation material for industrial furnace

- Ceramic fiber blanket can be used.Ceramic fiber blanket color white, regular size, set fire, heat insulation, insulation in one. Free from any binding agent.

- Q:What is industrial furnace masonry?

- Before masonry construction, the pre process and parts that may affect the quality of masonry work shall be re tested,masonry construction shall be carried out according to the datum central line and the datum elevation.

- Q:How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PC Steel Bar Complete Induction Heating Equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 25 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords