PC Series Hammer Crusher Hot Sales for Mining Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PC Series Hammer Crusher Hot Sales for Mining Industry

General Information

Hammer crusher is a crushing machine to crush medium hardness and brittle rocks and ores to smaller pieces by repeated blows of high speed rotating hammers.

Materials for used hammer crusher

Hammer crusher is suitable for grinding many kinds of medium hardness and brittle materials, such as limestone,coke, coal, calcite, marble, kaoline, gesso, barite etc.

Specification:

Type | Max Material-in Size | Material-out Size | Yield | Motor Power | Machine Weight |

2PG-400x250 | 25 | 1-8 | 5-10 | 11 | 1500 |

2PG-610x400 | 40 | 1-20 | 13-35 | 30 | 4500 |

2PG-750x500 | 40 | 2-20 | 15-40 | 37 | 12250 |

2PG-900x500 | 40 | 3-40 | 20-50 | 44 | 14000

|

Features and benefits of used hammer crusher

1.The discharging particle size is adjustable, for a certain grain size, you can get the qualified particle size just by one time crushing.

2.Carbon structural steel frame, high manganese steel bearing chock, superior alloy steel shaft.

3.Lining plates and impact plates are made of casting high manganese steel with hardening treatment.

4.Hammer rack and hammer bore are made of carburizing high manganese steel with heat treatment.

5.Hammer heads adopt new multielement composite casting high chromium manganese steel.

Working principle of roll crusher:

When the hammer crusher is working, the hammers rotate at a high speed, the materials fed into the crushing cavity are impacted to smaller parts by hammers and impact boards, the qualified particles are expelled through screens at the bottom of the crusher of a selected size, the unqualified parts will be crushed again till to the qualified size.

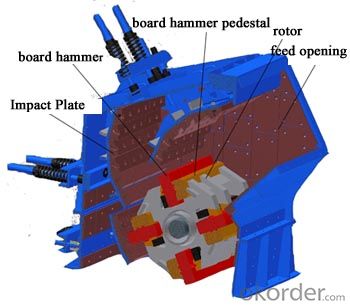

Structure of roll crusher:

Other types of Crusher:

Stone Crusher:

PE Series Jaw Crusher:

Roller Crusher:

FAQ:

1. Delivery time

We guarantee that your crusher will be ready within 45 days after receipt of your down payment.

2. Warranty

We provide one year warranty for every crusher.

3. what kinds of service can be provided to customers

Many thanks for your trust , we can provide you with proposal chart for complete production lines ,

spot inspection and operator traning according to your demands and the conditions of applied spot , we can help you

choose the right equipments ,drilling rig ,loader ,trucks ,excavators and so on .

- Q:I work at a retail store that deals cell phones, mobile broadband, etc. It is one of the Top 4 cell phone companies in the US. Anyway, the manager and the assistant manager were both lesbians. They carried on kind of a flirtatious relationship for the past yearlet's just say it was obvious they were friends. But the store constantly had chatter of sexual nature, and most of it was overly graphic. The other people in the store were sort of bothered by this, especially what they considered favoritism shown to the assistant manager by the manager, both who are lesbians. So the other day the district manager walks in. He talks to a couple employees. Then he talks to our manager. Then next thing I hear is that she's fired. My state is an 'at-will' state, but I pose the question to you guys - did he have to fire her for this conduct? Can she possibly file for wrongful termination? Could he have faced a lawsuit if the guys in my store claimed they felt sexually harassed by the sexual overtones of the conversations?

- You could do skullcrushers with a regular barbell, but I prefer the EZ-bar or dumbbells. Just think of it as a tricep extension, where you concentrate on squeezing your tris during the movement. You move it either to your face or behind it (whichever is more comfortable) and keep your elbows in.

- Q:I am interested in portable jaw crusher , is any one specialized in this aspect?

- Great okorder /

- Q:i'm doin a planning and designin lab for school and i need to test Orange juice for citric acid what do i do?

- i got the p90x about a month ago and i can tell u it does work as long as you follow through the diet and excersizes. It isn't even as easy as it seems. 1st day i could barley get done with day one. week later i finished day 1. week after that i am doing more push ups and pullups. What i do is i open up the cd thingy they mailed u the black packet of dvd's and start he first disc. that is my day 1. next day i will do the next disc that will be day 2. and so on.. once i hit day 6 after that i stop and day 7 is my resting day so i wont do p90x. then after day 7 day 8th i will continue or if i hit the end of the dvd packet i will restart at the beggining again and do that for the whole 90 days. I am currently off the p90x because i keep messing up my diet by eating junk food but come this weekend i will start it again and trust me you will feel it after the 1st 3 days you can already notice improvments if you go through the diet and excersizes you will see a bigger chest etc.. PS- the ab crusher thing is basicly after every other day like day 1 day 3 day 5. you will do th ab crusher workouts. to me i like to do it everyday for a better result and faster. you can do it too i guess but i would suggest you follow the dvd's like the 1st dvd on day 1 2nd dvd day 2 etc.. they work on certain body parts say for example day 1 works on chest and back day 2 will work on cardio/leg giving ur back and chest and arms a day off then day 3 will work on arms and somehwta chest/back again. that way you dont stress yourself.

- Q:i was just wondering how many smoke detectors are suppose to be in a 2 bedroom apartment? also what i can do for my landlord entering my apartment when i was not home. before this he sexually harrased me by smacking my butt two times. he also was saying really dirty things to me. i am afraid he may have went through my personal things. there is also regular harrasment. when ever i have a friend or family member over he stares out his window or goes to the front hall to listen to what im saying. i had 2 friends sleep over last weekend friday and saturday night, the landlord sent me a text saying 'keep in mind this is not a ymca if you want to have people sleep over we will have to talk about raising the rent' i pay my rent every week and dont think i should be harrased and embarassed like that. on top of that i pay my own utilities..electricity heat hot water. please give some advice on what to do.

- Two things really here. One and is the most important, You could be putting many other peoples lives at risk by tampering with a fire alarm system. There is absolutely no reason for you to do this.Second, call reception and tell them what is happening so it can be corrected.

- Q:how to calculate the compression for cans? because my group want to do cans crusher machine?

- The steel or aluminum for cans comes in a few standard thicknesses. The cans come in a wide variety of shapes and sizes with different types of seams. In worst case scenario, the crusher may fail to crush several cans simultaneously. You want that to happen very rarely, so the crusher should apply about 500 kilograms = 1100 pounds pressure to the cans. Neil

- Q:If you jailed me in your house, what part would I be locked up in?

- -Dollywink Liquid Eyeliner: Never tried it. -Stila Eyeliner Pen: Never tried it. I heard it was amazing, but honestly, I think if you want a -really good liquid eyeliner pen, get the L'Oreal Lineur Intense Felt Tip Eyelinerit's awesome! -Jordana Fabulin

- Q:The direction of rotation of the spindle of the hammer crusher and the distance between the hammer and the sieve

- The direction of rotation is determined by what is on the stand, facing the feed port, and at the right side of the feed port, it should be clockwiseThe distance between the hammer head and the screen is not fixed, and the thickness of the material can be adjusted according to the thickness of the material. The larger the distance is, the thicker the material is, and the smaller the material is discharged

- Q:This is a Photon Deck I posses and it currently only has 39 cards. Please tell me what the last one should be.Monsters 20Effect VeilerPhoton Lizard x2Photon Sabre Tiger x3HonestPhoton Crusher x3Photon Thrasher x2Cyber Dragon GorzBeast King Barbaros x3Galaxy-Eyes Photon Dragon x3Spells 10Dark HoleFuture FusionHeavy StormMonster RebornMystical Space Typhoon x2Photon Lead Photon SanctuaryPot of Duality Reinforcement of the ArmyTrapsBottomless Trap Hole Call of the HauntedCompulsory Evacuation DeviceDark BribeDimensional PrisonMirror ForceSakuretsu Armor Skill Drain x2

- Monsters 16 Photon Sabre Tiger x3 Honest Photon Crusher x3 Photon Thrasher x3 Beast King Barbaros x2 Thunder King Rai-Ohx23 Maxx Cx2 Spells 12 Dark Hole Monster Reborn Mystical Space Typhoonx3 Photon Tridentx3 Pot of Dualityx3 Reinforcement of the Army Traps12 Bottomless Trap Holex2 Solemn Judgment Solemn Warningx2 Dimensional Prisonx2 Torrential Tributex2 Skill Drainx3

- Q:can i disconnect the heater hose from the fire wall to stop the steam come from my the window on a 98 eldorado?

- the ONLY thing an apartment complex is required to provide is running water (and it doesn't have to be heated as it's used for the toilet, for sanitation). Landlords will not let you move in unless you've called the electric company, gotten an account in your name and paid the deposit and have electricity in your apartment.

- Q:who lives in longwood? i have a dog walking service and i need some costumers?

- for biceps do bicep curls, hammerhead curls. for triceps do skull crushers, french press, overhead extensions. try doing different styles of pushups such as narrow to wide hand placements to diamond pushups.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PC Series Hammer Crusher Hot Sales for Mining Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products