PC Purline Making Machine Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PC Purline Making Machine Production Line

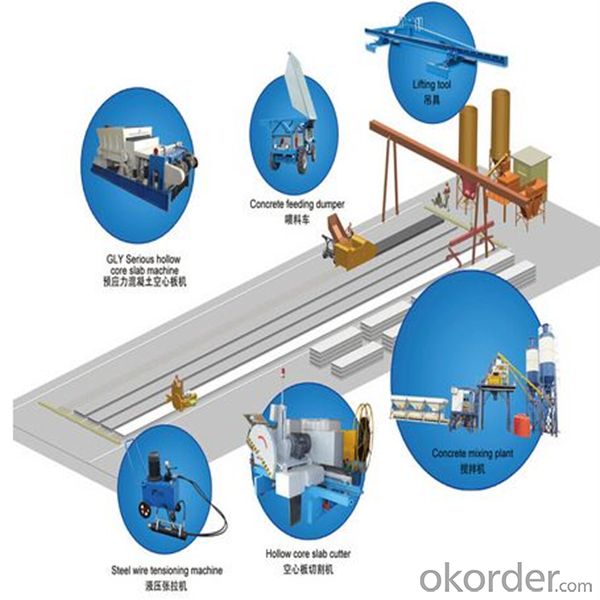

1. Structure of PC Purline Making Machine Production Line:

PC Purline Making Machine Production Line is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of PC Purline Making Machine Production Line:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. PC Purline Making Machine Production Line Images:

4. PC Purline Making Machine Production Line Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

Production Line Layout

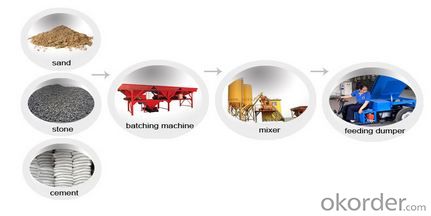

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:How long would it take a farmer to harvest crops in a 1 mile radius with out machinery?

- It doesn't matter because if the farmer started to harvest the crops when they were ripe, he or she wouldn't be able to pick them all before they started to rot in the field. The farmer would need a lot of help. The more help, the less time it would take.

- Q:Mechanical material forming cold forming and thermoforming What is the difference, the main processing of what materials

- the role of environmental gravity without stretching without deformation.

- Q:What is the processing of materials?

- It is related to the chemical composition, mechanical properties, thermal conductivity and work hardening degree of metal materials.

- Q:Or do I have to claim my business as a medium size cooperation?

- Why the hell not?! If President Bush can be an idiot, normal citizens should be able to be as well!! (I am an Australian anti-Bush person - sorry if I have offended anyone)

- Q:I want to be an engineer who works with microchips and things like that. Are there any small projects and things which I could do at home (spending less than $100-200) just to get a feel for things?

- www.okorder / first get a grip on the basics

- Q:Is machinery still being built?

- yes it is

- Q:Presented here are selected transactions for Snow Company for 2012.Jan. 1Retired a piece of machinery that was purchased on January 1, 2002. The machine cost $66,300 on that date and had a useful life of 10 years with no salvage value.June 30Sold a computer that was purchased on January 1, 2009. The computer cost $31,200 and had a useful life of 5 years with no salvage value. The computer was sold for $12,480.Dec. 31Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $53,000 and was depreciated based on an 8-year useful life with a $6,300 salvage value.Journalize all entries required on the above dates, including entries to update depreciation, where applicable, on assets disposed of. Snow Company uses straight-line depreciation. (Assume depreciation is up to date as of December 31, 2011.)

- Hey I am here for the first time. I found this question and I find the replies truly useful. I hope to offer something back to the community and assist others too.

- Q:Can you convert Auto Cad drawings not Inventor drawings to use with CAM & CNC software & Machinery?

- yes you can i took a AutoCad class and the teacher showed us how to convert AutoCad drawings to mastercam

- Q:would these include non motorized equipment used for processing?

- farm machinery, mechanical devices, including tractors and implements, used in farming to save labour. Farm machines include a great variety of devices with a wide range of complexity: from simple hand-held implements used since prehistoric times to the complex harvesters of modern mechanized agriculture.

- Q:I need to find info on this and I haven't found a thing....[if your gonna answer with stupid retarded answers then don't I'm doing a project not a plaything]

- History okorder /

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PC Purline Making Machine Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords