Parallel Twin Screw Extruder For Plastic CMAX-5000

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Technical parament

| model | CMAX-20 | CMAX-30 | CMAX-50 | CMAX-65 | CMAX-72 | CMAX-92 |

| Screw Dia.(mm) | 21.7 | 30 | 50.5 | 62.4 | 71.2 | 91 |

| Rotate.speed(r/min) | 600 | 400 | 400/600 | 500/600 | 400/500 | 400/500 |

| Main Motor(kw) | 4 | 11 | 11/15 | 55/75 | 90/110 | 220/250 |

| L/D | 32-40 | 28-48 | 28-48 | 28-48 | 28-48 | 28-40 |

| Output(kg/h) | 2-10 | 5-30 | 40-80 | 100-300 | 300-600 | 600-1000 |

Application

CMAX series parallel twin screw extruder is widely used for plastic modified granulation ,wood plastic composite granulation ,PVC granulation,PET granulation ect.

Features

It is mainly composed of high torque gearbox,meshed structure screw ,blending feeding system,exhaust system ,heating and cooling system ect.

Advantages

The meshed structure screw has excellent mixing and plasticazation ,comparing with other type extruder.

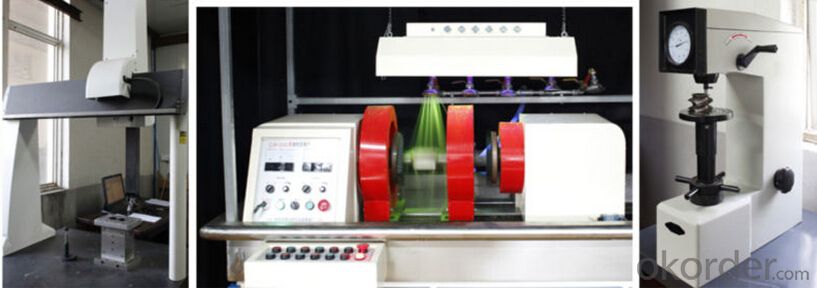

Product show

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q:the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q:Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q:Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q:Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q:What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q:Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part. Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q:Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q:How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

- Q:What are the components of an extruder?

- An extruder in which an air vent is disposed at the center of an exhaust extruder to allow removal of air and volatiles from the processed plastic. The main machine of plastic extruder is plastic extruderIt consists of an extrusion system, a drive system and a heating and cooling system. 1. extrusion system extrusion system includes screw, cylinder extrusion die head, extrusion die head, molding parts of the extruder. Also known as extrusion die, extrusion die. The utility model has the function that the plastic melt from the extruder barrel is well distributed in the die runner so as to be extruded and formed from the die at a uniform speed. The forming action of an extrusion die is in the process of complete extrusion (see plastics processing). A plastic extruder consists of an extrusion system, a drive system and a heating and cooling system. The classification system of extrusion system includes 1. extrusion screw, barrel, hopper, head, and mould, plastic extrusion system by plasticizing evenly into the melt, the establishment of Liu Hesheng basic information name in this process and Liu Hesheng taught: - professional engineeringControl science and EngineeringJob: in gender: Male College: College of mechanical and power engineering representative paper: melt rotating twin screw extruder in conveying flow solving teaching: research direction: mainly engaged in polymer material processingLinear low density polyethylene (LLDPE) linear low density polyethylene (LLDPE) linear low density polyethylene is structurally different from the generallow density polyethylene

- Q:1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Parallel Twin Screw Extruder For Plastic CMAX-5000

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords