Painted Aluminum Alloy Sheets for Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Painted Aluminum Alloy Sheets for Composite Panels

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Painted Aluminum Alloy Sheets for Composite Panels

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Painted Aluminum Alloy Sheets for Composite Panels

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

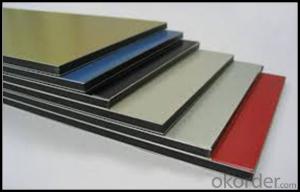

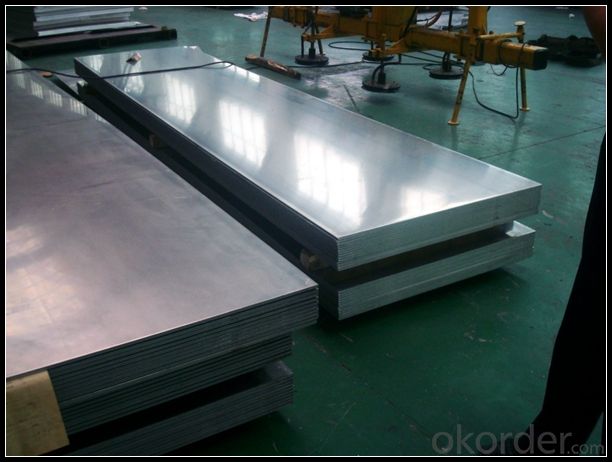

5. Image of Painted Aluminum Alloy Sheets for Composite Panels

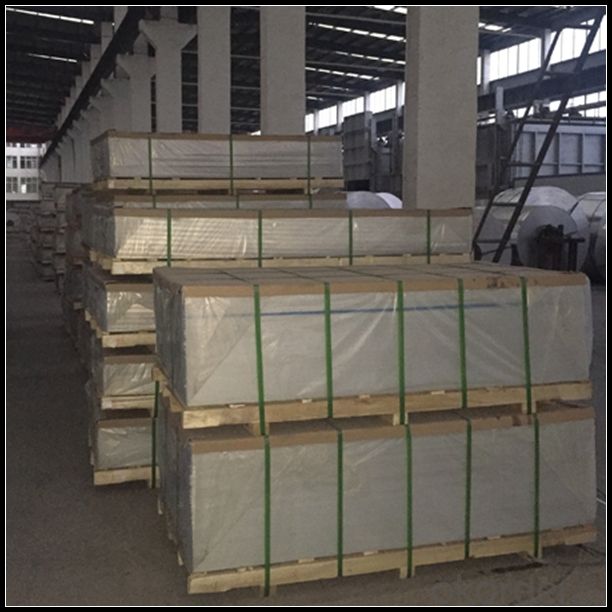

6. Package and shipping of Painted Aluminum Alloy Sheets for Composite Panels

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How much do aluminum sheets typically weigh?

- The weight of aluminum sheets ranges from 1.9 to 3.4 grams per square centimeter, and this varies depending on the sheet's thickness and size. Aluminum sheet weight can differ considerably based on its dimensions and gauge. Thinner sheets are typically lighter, while thicker ones tend to be heavier. It is worth mentioning that factors like the alloy utilized and any surface coatings or treatments can also impact the weight of aluminum sheets. Hence, it is recommended to refer to the product specifications or contact the manufacturer for precise weight details.

- Q:Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are suitable for signage applications. Aluminum is a lightweight and durable material, making it perfect for outdoor signs that need to withstand various weather conditions. It is resistant to rust and corrosion, which ensures the longevity of the sign. Aluminum sheets can be easily customized and cut into different shapes and sizes, allowing for versatile and creative signage options. Additionally, aluminum is a great material for digital printing and can provide high-quality graphics and images. Overall, aluminum sheets offer excellent durability, versatility, and aesthetic appeal, making them a popular choice for signage applications.

- Q:How do you prevent oxidation of exposed edges of aluminum sheets?

- One effective way to prevent oxidation of exposed edges of aluminum sheets is by applying a protective coating or sealant. This creates a barrier between the aluminum and the surrounding air, preventing the metal from coming into contact with oxygen and moisture, which are the main causes of oxidation. Additionally, storing the aluminum sheets in a dry and controlled environment can also help minimize the risk of oxidation.

- Q:What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot varies depending on the thickness of the sheet. On average, aluminum sheets weigh around 0.96 pounds per square foot.

- Q:as for heating coil and aluminum sheet, which one is better for heating?

- Both of them have advantage. It depends on the new product type it’s applied. Heating coil: it’s applied in some products with high temperature and large heat release, such as oven and other types.

- Q:Are 101 aluminum sheets suitable for cryogenic applications?

- Cryogenic applications are not suitable for 101 aluminum sheets. Although aluminum is generally a good choice for low-temperature environments because of its low thermal conductivity and high strength-to-weight ratio, 101 aluminum is not specifically designed to endure the extreme temperatures associated with cryogenic applications. In cryogenic applications, materials like aluminum alloys (for example, 5083 or 6061) or specialized cryogenic alloys like stainless steel or titanium are commonly used. These materials possess improved properties that allow them to handle the extreme cold temperatures without compromising their structural integrity. Therefore, it is advisable to use materials specifically designed for cryogenic applications to ensure optimal performance and safety.

- Q:How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- You can sprinkle the mix of Alkaline water,vinegar,washing powder and liquid detergent on the surface. And after a period of time, rub it with soft silk, after it being dry,sprinkle again and rub until it's clean.

- Q:What are aluminum sheets used for?

- Due to their unique properties and versatility, aluminum sheets find a wide range of uses. In the construction industry, they are commonly employed for roofing, siding, and cladding, thanks to their lightweight nature, corrosion resistance, and durability. These qualities make them ideal for such purposes. In the transportation industry, aluminum sheets are widely utilized in the manufacturing of automobiles, trains, and aircraft due to their high strength-to-weight ratio. They also serve as a lightweight yet sturdy solution for trailers, truck bodies, and shipping containers. Another significant application of aluminum sheets lies in the manufacturing of consumer products. They are used to make household appliances, cookware, and electronics, as they possess excellent thermal conductivity and resistance to rust and corrosion. Additionally, their ability to withstand various weather conditions makes them suitable for the production of signage, billboards, and displays. In the packaging industry, aluminum sheets play a crucial role in the production of cans, foils, and lids. Their impermeability to light, moisture, and oxygen helps preserve the freshness and quality of food and beverages. Moreover, aluminum sheets have various industrial applications. They are utilized in the fabrication of industrial machinery, equipment, and tools due to their excellent machinability and strength. Additionally, their thermal and electrical conductivity makes them suitable for the production of heat exchangers, solar panels, and electrical conductors. In summary, aluminum sheets find application in construction, transportation, consumer products, packaging, and various industrial sectors, owing to their lightweight, corrosion resistance, durability, thermal conductivity, and electrical conductivity.

- Q:Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Polishing aluminum sheets involves smoothing the surface and creating a reflective finish using abrasive materials or polishing compounds.

- Q:Can the aluminum sheets be used for manufacturing heat shields?

- Aluminum sheets are capable of being utilized in the production of heat shields. Renowned for its remarkable thermal conductivity and remarkable heat resistance, aluminum is extensively employed in multiple sectors, such as automotive and aerospace, for the manufacturing of heat shields. The reflective and heat dissipation properties of aluminum sheets enable them to effectively counteract heat, rendering them an optimal material for this specific purpose. Furthermore, aluminum possesses the advantages of being lightweight and corrosion-resistant, thus making it a sensible selection for heat shield production.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Painted Aluminum Alloy Sheets for Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords