Packing film PVC Stretch Film made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

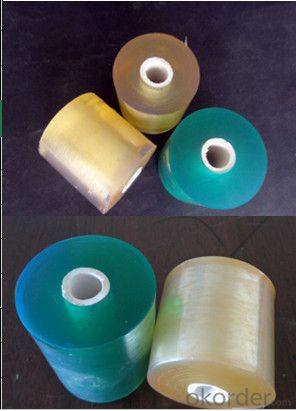

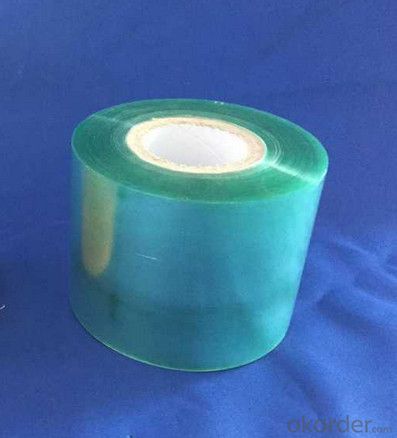

PVC Stretch Film

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q:Building floor pouring why plastic film underneath?

- This is a relatively old waterproof and moistureproof way, the effect is good, and now waterproof materials are multifarious, most of the materials are less than the effect of doing so

- Q:Is plastic film the same as glass cloth?

- The material is different, not to mention the process

- Q:What are the plastic film types and scope of use?

- LDPE films are usually made of two kinds of blow molding and tape casting. Cast PE films are of uniform thickness, but are widely used because of their high cost and low cost. LDPE film is a semi transparent, glossy and soft film with excellent chemical stability, heat sealing property, water resistance and moisture resistance. It can be frozen and boiled. The main drawback is that the oxygen barrier property is poor, the inner membrane is commonly used in soft packing materials, and is currently the most widely used, one of the largest amount of plastic packaging film, accounting for more than 40% of the consumption of plastic packaging film.Due to the polar group containing polyethylene molecules, and high crystallinity, low surface free energy, therefore, the poor performance of the film printing, ink and adhesive adhesion is poor, so the surface treatment in printing and composite before.

- Q:Early spring seedlings using light blue plastic film or white plastic film?

- The blue film absorbs light, which is converted to carbohydrates by chlorophyll, and is covered with white film. The light is too strong and the seedlings die easily. Therefore, we should pay attention to the use of choice, so that the healthy growth of seedlings.

- Q:Method for removing stainless steel plastic film

- Because of their environmental protection characteristics, many water-soluble films have attracted extensive attention in developed countries all over the world. Abroad are Japan, the United States and France etc. the production and sales of such products, such as the United States W.T.P company, C.C.L.P company, GRENSOL company in France and Japan synthetic chemical company and so on, the user is also some well-known large companies, such as Bayet (Bai Er), Henkel (Henkel), Shell (Shell) etc..

- Q:Is there any material in the strong film made of plastic material which is resistant to high temperature, piercing, and has high tensile properties and can not tear off the film?

- High temperature resistance, piercing resistance, and high tensile properties, tear, all these properties of the film should be LLDE film.

- Q:Is the foundation covered with film or damp proof powder?

- And moisture-proof powder is similar to desiccant, moisture can only be, but if the humidity is relatively large or too much water, then the performance is not as good as the film. So it is better to use film to prevent moisture on foundation, but don't damage it during construction.

- Q:PVC and PE plastic film, which can be used as food preservative film?

- PE plastic wrap can be used to wrap food. Because PE made of plastic film is harmless to human body.

- Q:Can electrostatic generator adsorb plastic film?

- An electrostatic generator can be used to adsorb plastic films;ESD (electrostatic discharge generator) is mainly applied to the ESD test of human body metal model for system level electronic equipment, such as mobile phone and computer, including electrostatic generator and electrostatic discharge gun;

- Q:Keyboard circuit board, film paper and rubber strip, how is it installed?

- In the side of the conductive thin film circuit and the circuit board finger contact.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Packing film PVC Stretch Film made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products