Package Box Made from Color Logo Design Paper Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Package Box

Package Box are made of hard paper coated with acrylic adhesive on both sides.

Application of Package Box

1. Industrial box parking

2. general purpose repair

3. gift wrapping &decoration

4. outside electronics product packing with safety material

5. bundling &strapping

6. stationery purpose

Advantage of Package Box

1.superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of Package Box

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100pcs/carton(according to different specifications)

carton size : any carton size as your request

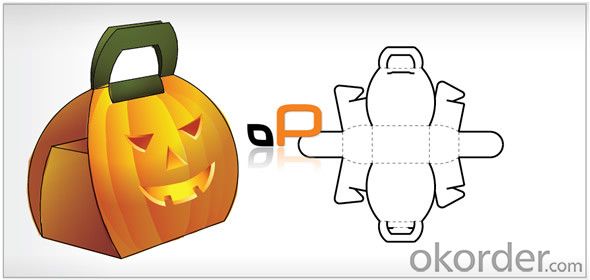

Pictures of Package Box

Specification of Package Box

| Material | PVC, PET, APET, PETG, PP,paper |

| Size/Shape | Customized |

| Thickness | 0.25mm-0.8mm |

| Variety of Products | Folding boxes, Tubes, Thermoformed, Die-cut products |

| Printing Options | UV offset printing, silkscreen printing, foil stamping, special effects printing |

| Full color comps of receipt of artwork time | Within a week |

| Packaging | Single packed, shrink film packed, depend on customer’s request |

Remarks of Package Box:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your package box have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q:What kind of wood is commonly used in wooden packing boxes?

- Wood packaging is one of the oldest packaging containers, the amount of wood packaging in packaging after the paper packaging container, and wood packaging in developing countries than in developed countries and the amount is much larger, therefore, wooden packaging container occupies a very important position in the packaging container.

- Q:What's the name of the material used in paper packing boxes?

- Honeycomb paperboard featuresThe honeycomb cardboard is made according to the principle of nature of the honeycomb structure, it is the connection of corrugated paper into numerous hollow three-dimensional hexagonal glue bonding method, form an overall stress - paper core, environmental protection and energy saving materials of a new type of sandwich structure and on the two sides of the adhesive paper. Honeycomb paperboard is mainly characterized by:(1) light quality, little material and low cost. Compared with other kinds of sheet structures, honeycomb sandwich structure has the largest strength / mass ratio, so its performance / price ratio is good, which is the key to the success of honeycomb paperboard.(2) high strength, smooth surface, not easy to deformation. Honeycomb sandwich structures are approximately isotropic, have good structural stability and are difficult to deform, and their outstanding compressive and flexural capacity are the most important characteristics required for box type packaging materials.(3) shock resistance and good cushioning. The honeycomb cardboard made of flexible paper core and made of paper, has good toughness and elasticity, honeycomb sandwich structure provides a unique buffer with excellent performance, with all the materials in the buffer unit volume of higher energy absorption value, high thickness of honeycomb paperboard can be EPS foam cushioning plastic pad has the extensive use of the alternative.(4) sound absorption and heat insulation. The interior of the honeycomb sandwich structure is a closed chamber filled with air, so the utility model has good sound insulation and heat insulation performance.(5) pollution-free, in line with the trend of modern environmental protection. The honeycomb paperboard is made entirely of recycled paper material and can be recycled and recycled in one hundred percent places after use.

- Q:Is the outer packing case and the turnover case a concept?

- Is not a concept, the outer packing box refers to the original packaging of the product, usually paper, and the turnover box refers to the product turnover packaging, there are protective products, optimize the role of storage and transportation, usually plastic.

- Q:What are the requirements for product packaging?

- Non packaged products should be stored in rainproof, ventilated and dry places. And the product pad, in order to prevent moisture damage.The product must be inspected by the quality inspection department and accompanied by a product qualification certificate. The products must be inspected by the packing inspector before packing.Before packing, the dust and other dirt on the product must be removed. The whole packing process must be cleaned so as to ensure the quality of packing. Explosion proof electric products and power transmission control device should be covered with plastic bags and then put into the packing box. The outer packing is made of simple packing and should be packed in plastic bags first.

- Q:What enterprises need wooden packing box?

- Material classification1. Wooden packing box: packing container made of wood and bamboo.2. No fumigation packing box: packing container made of composite material.3, strong safety: plastic packaging container for patent engineering plastics made by special technology.4, corrugated packaging box: it is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q:What are the standards for carton boxes?

- Six angle drum turning testPut the carton into the six corners revolving drum with the impact plate, rotate according to the specified number of revolutions and times, and then check the damage of the goods and cartons.The above dynamic experiments are destructive and improve the resistance to damage of cartons and commodities by using cushion linings, partitions or other protective measures in the packaging of goods. In addition, some cartons need to be tested for spraying, weather resistance, etc., according to the contract agreement between the two parties.

- Q:How can I remove the words from the wooden packing box?

- Rub it slowly with a corner grinder and wipe it out

- Q:Is the packing box for express delivered by ourselves or by courier company?

- Courier companies give paper boxes, but if things are loose, you should pack them first.

- Q:What are the requirements and procedures for exporting wooden packing boxes?!

- The export packing box is made of various kinds of wooden waste materials which are treated by high temperature and high pressure. The wooden box has high compressive resistance and Gao Chengzhong performance. Meanwhile, it avoids the defects of wooden knot, moth eaten, color difference and humidity in the traditional wooden case

- Q:What's the maximum size of the export packing box? What's the maximum size?

- And if the product itself is relatively large, then some of the packing box must also be very large (such as bicycles, furniture products), this category is generally used forklift loading and unloading. Then the carton will be arranged according to the actual size of the product. However, in order to achieve better packaging effect, it is better to use pallets as packaging units, so that it is not easy to use the forklift for loading and unloading.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Package Box Made from Color Logo Design Paper Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords