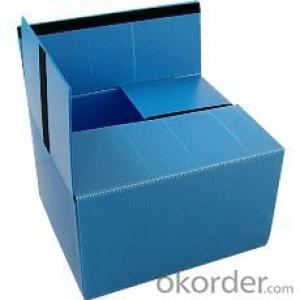

Package Box Hard for Different Products with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Package Box

Package Box are made of hard paper coated with acrylic adhesive on both sides.

Application of Package Box

1. Industrial box parking

2. general purpose repair

3. gift wrapping &decoration

4. outside electronics product packing with safety material

5. bundling &strapping

6. stationery purpose

Advantage of Package Box

1.superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of Package Box

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100pcs/carton(according to different specifications)

carton size : any carton size as your request

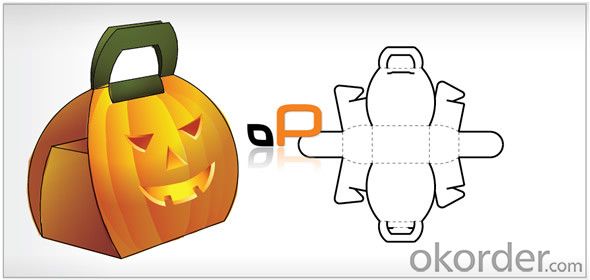

Pictures of Package Box

Specification of Package Box

| Material | PVC, PET, APET, PETG, PP,paper |

| Size/Shape | Customized |

| Thickness | 0.25mm-0.8mm |

| Variety of Products | Folding boxes, Tubes, Thermoformed, Die-cut products |

| Printing Options | UV offset printing, silkscreen printing, foil stamping, special effects printing |

| Full color comps of receipt of artwork time | Within a week |

| Packaging | Single packed, shrink film packed, depend on customer’s request |

Remarks of Package Box:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your package box have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q:How about a carpenter's packing case?

- The vertical direction of the core plate (the difference between the core and the material) is poor, but the lateral flexural strength is higher. Both nail grip and water repellency are availableBetter than MDF and chipboard. The surface is generally rough and needs finishing (paint or decorative panels etc.). Simply speaking,A large piece of carpentry that must be nailed at home usually requires a large core board.But the large board itself uses a lot of glue, and a lot of glue or paint will be used in the finish, and the core boardPollutants are in open volatile state, so, home improvement must strictly control the use of large core board.

- Q:What are the requirements for product packaging?

- Non packaged products should be stored in rainproof, ventilated and dry places. And the product pad, in order to prevent moisture damage.The product must be inspected by the quality inspection department and accompanied by a product qualification certificate. The products must be inspected by the packing inspector before packing.Before packing, the dust and other dirt on the product must be removed. The whole packing process must be cleaned so as to ensure the quality of packing. Explosion proof electric products and power transmission control device should be covered with plastic bags and then put into the packing box. The outer packing is made of simple packing and should be packed in plastic bags first.

- Q:How to calculate the cost of producing the packing box?

- The production of corrugated cardboard cartons enterprises generally use varieties of costing, according to industry varieties open cost sheet.The direct materials need distribution, workshop production to issue requisitions, is the number into the number of the cost. Direct materials include a variety of paper and adhesives (corn flour or water glass), if they are flat nails and can be incorporated into supplementary material.

- Q:What enterprises need wooden packing box?

- Material classification1. Wooden packing box: packing container made of wood and bamboo.2. No fumigation packing box: packing container made of composite material.3, strong safety: plastic packaging container for patent engineering plastics made by special technology.4, corrugated packaging box: it is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q:What are the L and R stands for steel cord packages?

- If the direction of the take-up is not correct, the spindle room worker will need to turn a single body to push the spool into the spool to increase the workload of the spindle room worker.

- Q:How can the packing box be mounted onto the board?

- There are two kinds of steel box: one is a steel belt with a tray, and two is a wooden box without a tray. Compared with the traditional wooden case, its characteristic is: it is easy to disassembly, reliable connection: products can be folded after storage, and the use of steel edge connection, greatly reducing the transportation cost, effectively saving storage space. It is a good choice for long-term transportation and long-term storage. It is suitable for packing articles under the weight of 2 tons. Usually, the box can be split into six pieces (S type) or three (P), which is easy to transport and assemble when used. The length is usually around 300mm - 2000mm.

- Q:Can the express company provide the computer's packing box?

- When mailing an item, the courier company may provide a package service for the sender, but there is no requirementProvide the packaging with the goods needed by the sender.Solution: if you send a computer, you can communicate with the courier in advance,The package needed for the purchase of the package must be carried by the sender

- Q:How do I distinguish between package types?

- Packaging container shape classification: can be divided into packaging boxes, packaging barrels, packaging bags, packaging bags, packaging baskets, packaging bundles, packaging jars, packaging cans, packaging tanks, bottles and so on.

- Q:What are the requirements for export packing?

- To adapt to the characteristics of the goods, to prevent damage to the goods, deterioration, pollution and other losses occurred.

- Q:What's the maximum size of the export packing box? What's the maximum size?

- 0262-93 described in this way: Carton support molding, the adjacent angle of 90 degrees, with an internal diameter of the tongue in the tongue, from the box mouth50mm don't take long and the amount of punishment box to box width, box bottom and top two in the distance between the roll cover box. But in the amount taken before a step must be made: one end of the swing cover together and support the carton forming, adjacent surface angle 90 degrees to gauge, the inner box with plate cover close to the box top outside shake cover open, the wooden ruler level

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Package Box Hard for Different Products with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords