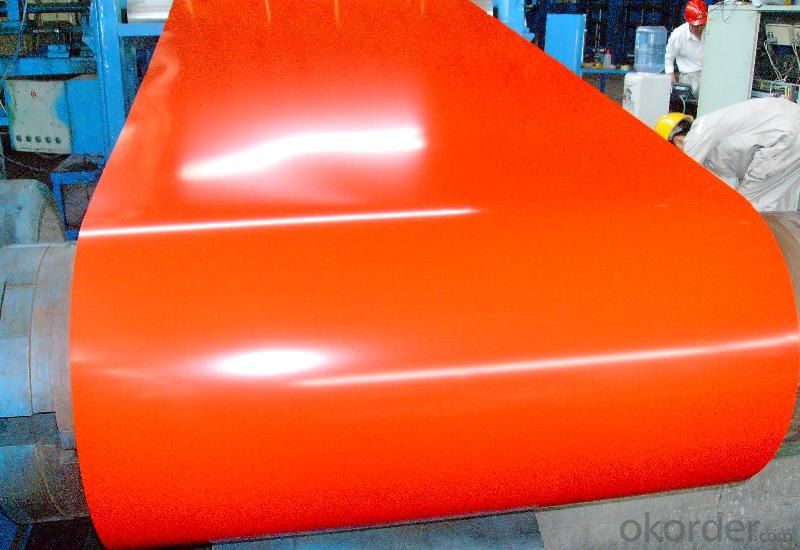

Orange Color Pre-Painted Galvanized/Aluzinc Steel Sheet in Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:What are the common packaging defects in steel coils?

- Steel coils can have various packaging defects. These include edge damage, rust or corrosion, coil slippage, coil damage during handling, inadequate protection against impacts, improper coil strapping or banding, and insufficient labeling or identification. When the edges of the steel coil are not properly protected or wrapped, it can lead to dents, scratches, or deformities. This compromises the coil's integrity and can result in reduced performance or structural issues. If steel coils are not adequately protected during packaging, they can be prone to rust or corrosion. Moisture or harsh environmental conditions can cause oxidation, resulting in rust spots or widespread corrosion. This weakens the steel and makes it less suitable for its intended use. Improper packaging can cause the coils to shift or slip within the packaging material during handling or transportation. This can lead to misalignment, deformation, or interlocking, making it difficult to separate or use the coils effectively. Rough handling, improper lifting techniques, or inadequate support can cause mechanical damage to the steel coils. This can result in dents, scratches, or more severe structural damage, impacting their functionality or performance. Steel coils need sufficient protection against impacts during transportation or storage. Insufficient padding or cushioning can lead to deformities, dents, or fractures in the coil due to impacts or collisions. If the strapping or banding used to secure the steel coils is not properly applied or tightened, it can cause coil slippage or even complete unraveling of the packaging. This creates a tangled mess of steel coils, making them difficult to handle, transport, or use. Proper labeling and identification are crucial for efficient handling, storage, and tracking of steel coils. Inadequate or incorrect labeling can cause confusion, delays, or even loss of the coils during transportation or storage. To prevent these packaging defects, it is important to follow proper guidelines, use appropriate materials, provide adequate protection, and ensure proper labeling and identification of steel coils. Regular inspections and quality checks throughout the packaging process can help identify and rectify any defects before shipping or use.

- Q:What are the different coil slitting methods used for steel coils?

- There are several coil slitting methods commonly used for steel coils. These methods are employed to cut larger steel coils into smaller, narrower coils that are suitable for specific applications. 1. Blade Slitting: This is the most common method used for coil slitting. It involves using circular knives or blades to cut the steel coil into narrower strips. The blades are set at predetermined distances and are usually mounted on a rotating shaft. The coil is passed through the blades, and the circular motion of the blades slices through the coil, creating the desired narrower strips. 2. Rotary Shear Slitting: In this method, two sets of rotary shear knives are used to cut the steel coil. The upper and lower sets of knives rotate in opposite directions, creating a scissor-like cutting action. The coil is passed through the shearing blades, and the sharp edges of the knives slice through the coil, producing the desired narrower strips. 3. Sliding Shear Slitting: Sliding shear slitting is another method used for coil slitting. In this method, a stationary upper knife and a moving lower knife are used to cut the coil. The lower knife moves back and forth across the coil, while the upper knife remains stationary. The coil is passed through the moving knife, which cuts it into narrower strips. 4. Crush Slitting: Crush slitting is a less common method used for coil slitting. In this method, the steel coil is passed through a set of rollers equipped with blades. The blades are not sharp, but the pressure exerted by the rollers crushes and fractures the coil, creating the desired narrower strips. 5. Laser Slitting: Laser slitting is a modern and precise method used for coil slitting. It involves using a laser beam to cut through the steel coil. The laser beam is directed onto the coil, and its high intensity melts and vaporizes the steel, creating a narrow slit. Laser slitting offers high accuracy and a clean cut, making it suitable for specialized applications. Each of these coil slitting methods has its advantages and limitations, and the choice of method depends on factors such as the type of steel, desired strip width, production volume, and required precision. Manufacturers select the most appropriate method based on their specific requirements and the properties of the steel coils they are processing.

- Q:How are steel coils used in the production of agricultural equipment?

- Steel coils are used in the production of agricultural equipment as they serve as the primary material for manufacturing various components such as frames, brackets, and structural supports. These coils are shaped, cut, and welded to create the required parts, which are then assembled to form agricultural machinery like tractors, plows, and harvesters. The strength and durability of steel make it an ideal choice for withstanding the demanding conditions and heavy workloads typically associated with agricultural equipment.

- Q:What are the common coil surface finish standards?

- Some common coil surface finish standards include mill finish, brushed finish, polished finish, and coated finish.

- Q:What are the different types of steel coil packaging materials used during processing?

- There are several different types of steel coil packaging materials used during processing, including steel strapping, plastic strapping, stretch film, corner protectors, edge protectors, and wooden crates.

- Q:How do steel coils contribute to sustainable construction?

- Steel coils contribute to sustainable construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures made from steel coils have a longer lifespan and require less maintenance and replacement over time. This reduces the amount of waste generated and resources consumed in the construction industry. Additionally, steel is a recyclable material, so steel coils can be easily recycled and reused, reducing the demand for new steel production and minimizing the environmental impact. Steel is also a lightweight material, which allows for more efficient transportation and installation, reducing energy consumption and greenhouse gas emissions. Finally, steel coils offer excellent structural strength, enabling the design of more sustainable and energy-efficient buildings with reduced material usage, increased energy efficiency, and improved safety. Overall, steel coils play a crucial role in promoting sustainability in construction through their durability, recyclability, lightweight nature, and structural benefits.

- Q:melting point, as compare to stainless steel

- Be *real cautious* using HCL round stainless. A lowering acid like HCL will wreck down the oxide layer on the stainless, and corrosion will proceed. So far as i do know, there is not any scale down level at which HCL will not attack the skin oxide, however at very low concentrations maybe somewhat rust/pitting/corrosion is not going to be a main issue. Oxidizing acids like nitric, and to a couple measure sulfuric, will passivate stainless under the right conditions. But on simple, mild steels, corrosion will proceed to form FeCl and FeSO4 corrosion merchandise. The corrosion will haven't any outcomes on tensile, hardness or affect until ample fabric has been eliminated via corrosion to make a measurable change. Hydrogen embrittlement is a likelihood if there's constant anxiety, and hydrogen is advanced in corrosion. Whether or not it is a challenge would rely on the drawback.

- Q:Whats the difference in composition? When LTCS is used generally?Whats the temperature range, that these materials can be used? Is there any relation between Killed carbon steel, LTCS, stainless steel, carbon steel(normal)? How to categorise/classify these?Thankyou very much in advance..

- This Site Might Help You. RE: What is the difference between LTCS and Carbon steel? Whats the difference in composition? When LTCS is used generally? Whats the temperature range, that these materials can be used? Is there any relation between Killed carbon steel, LTCS, stainless steel, carbon steel(normal)? How to categorise/classify these? Thankyou very much in advance..

- Q:Steel, Sturm, and Kitiara are in a series called the Dragonlance Chronicles.

- Steel Brightblade

- Q:How are steel coils used in the production of automotive frames?

- Steel coils are used in the production of automotive frames as they provide the necessary strength and durability. These coils are typically formed into specific shapes and sizes, which are then welded together to create the frame structure. The high tensile strength of steel coils ensures that the automotive frame can withstand the various stresses and strains experienced during vehicle operation, ensuring safety and stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Orange Color Pre-Painted Galvanized/Aluzinc Steel Sheet in Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords