Operate Flexibly Complete Pet Bottling Line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

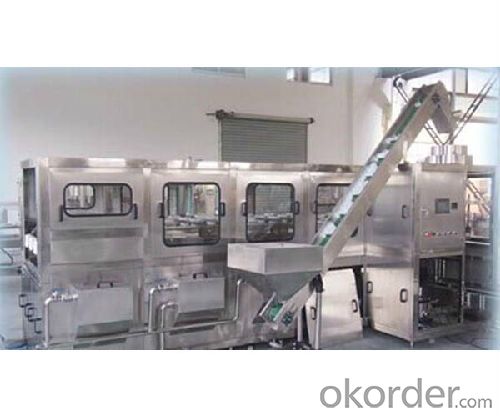

Operate Flexibly Complete Pet Bottling Line

1.Structure of Description

Water filling line/liquid filling line includes: Washing-filling-capping 3 in 1 machine, lamp inspection, label shrinking machine, inkjet printer, hot shrink film packer and conveyors. It is a full automatic production line.

The water filling line is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machinery of the same specifications.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

3. Images

4. Specifications

Type:Filling Machine

Application:Beverage

Packaging Type:Bottles

Packaging Material:Plastic

Rated Output:300 bottle/hour

Compressed Air Consumption:0.4Nm3/min

Water Consumption:7.4m3/h

Power:11.3KW

Model Number:QGF-300

Dimension(L*W*H):4080×1880×2200mm

Weight:2000KG

- Q:Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

- Q:What are the main functions of packaging machinery and equipment?

- Sealing and other major operations, and related processes before and after,

- Q:What's the best place to use the pillow type packing machine?

- In the early communication can be reflected, and sometimes non-standard customized to see the level of Technology

- Q:Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

- Q:Where is secondhand corrugated paper packaging machinery available?

- Start a small yellow cardboard box factory, they have the best business, began the purchase of machinery, plant hire.In an unfamiliar field, we should listen to the opinions of experienced people.Carton is a supporting product of consumer products, so to speak, as long as people have consumption, enterprises and products, there will be no lack of product packaging.

- Q:The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q:Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- English Name: Transparent, film, fold, wrapping, machineClassification: machinery, general machinery and equipment, >>J83 storage equipment, loading and unloading machineryICS classification: packing and conveying of goods, >>55.200 packaging machinery

- Q:Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q:What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q:Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Operate Flexibly Complete Pet Bottling Line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords