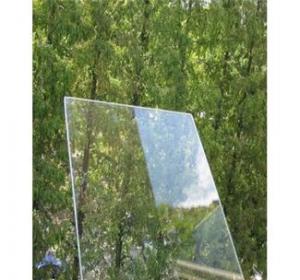

Offline Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low-E Glass is coated with low-E material-Silver, other low-E materials and metallic compound film over the surface of the glass, making the glass emissivity reducing from 0.84 to below 0.15. It not only has excellent energy efficiency, but also has decorative effects because of colors,and meanwhile has good processability(easy to be tempered, heat-strengthened,bent,insulating,laminated, etc.), thus becoming the first choice of architectural design. Theory for Energy Efficiency: By decreasing the U-value of glass and selectively lower the shading coefficient (Sc),It enables us to enhance the energy efficiency all sidedly.

In winter, silver coatings will reflect heat back to the interior of the building to prevent heat loss; In summer, silver coatings will reduce the re-radiation of heat to make the interior of the building cooler.

solid coatings will unite with glass into one.

the same lifetime of silver coatings with glass, stable properties, long storage

easy to process, dispose and store

natural color

no need of special treatment as the layers of insulating glass

biggest size: 3660*2440mm/3660*2134mm (size is subject to customization)

thickness: 4mm,5mm,6mm,8mm

conforming to the standard of GB T 18915.2-2008

- Q:Aluminum alloy window glass tape, how fast loading?

- The outer mounting method is that the operator stands on the scaffold or basket to carry out the glass installation of the aluminum alloy glass window. Fix the sealing strip first, fix the glass, then fix the outer side, and inject sealant into the cavity to fix the joint. This is a mix of dry and wet two materials.

- Q:Chemical materials and additives needed for the production of glass

- Production process of 1.3.1 glass1. Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) grinding, so that dry wet raw materialsDry, iron containing raw materials for iron removal, in order to ensure the quality of glass.2, batch preparation. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..3, melting. The glass mixture is heated in a bath or crucible furnace at a high temperature (1550-1600 degrees) to form a liquid glass that is uniform, free of bubbles and conforms to the molding requirements.

- Q:What are the construction principles and raw materials of tempered glass?

- Tempered glass, also called toughened glass, is a kind of prestressed glass. It uses physical or chemical methods to form a compressive stress layer on the surface of glass. The glass itself has a higher compressive strength and will not cause damage. When the glass is subjected to external force, the pressure layer may be part of the tensile stress offset, avoid broken glass, although tempered glass is in large internal stress state, but the glass no internal defects, without causing damage, so as to achieve the purpose of improving the strength of glass. It is well known that microcracks on the surface of materials are the main causes of material rupture. Because the microcrack will expand gradually under the action of tension, and finally crack along the crack. And because of the large compressive stress on the surface of the glass, the microcracks on the glass surface become more fine and even heal under the action of extrusion".

- Q:Not man-made destruction, why toughened glass suddenly broken?

- There are a variety of predisposing factors 2. tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q:List and characteristics of chimney glass flake cement

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale made of C- glass has excellent chemical durability.

- Q:What chemicals added to the PVB resin powder can be diluted into a transparent liquid?

- PVB film is a translucent film, the plasticized polyvinyl butyral resin by a polymer material plasticizing agent for extrusion molding. The appearance of translucent film, no impurities, smooth surface, there is a certain roughness and good softness, cohesion and good for inorganic glass with a transparent, heat resistance, cold resistance wet, high mechanical strength, is currently the world's best manufacturing adhesive material layer, safety glass, while building curtain wall, window, tent, recruit bank counter, prison has a wide application window, screen of steel furnace and various bullet proof glass construction field.

- Q:Cement / glass raw materials, equipment, principle, composition, characteristics, uses and types

- This is a useful feature because it prevents edges from becoming rounded, loss of tooth shape, and disappearance of surface imprinting, which is conducive to a vivid appearance. Kaolin hydrated aluminum silicate (Al2O3 2SiO2 2H2O), plays the role of adhesive to improve the forming ability of non sintered ceramic. Because of its opacity, the content is minimal. Although many repair ceramics contain free crystalline phases of quartz, they should be described as glass; rather, high melting ceramics can be called feldspathic glass". In the production of medium and low melting ceramics, the manufacturers mix various ingredients to melt them and then quench them in water. Quenching causes internal stresses, causing large cracks and fractures throughout the glass. This process is called the heating of glass material, and the product is called glass material. The brittle structure thus formed can easily be ground into powder for use by the porcelain artist. During the pre melting of ceramics, thermochemical reactions occur between the components, and the shrinkage associated with this reaction occurs. In subsequent chamber sintering, powders are fused together to form restorations. The melting temperature depends on the composition of the glass and must be carefully controlled to minimize thermoplastic flow. Potash (potash) and sodium (soda) is a carbonate or natural minerals (such as feldspar) to be introduced in the form of.

- Q:What are the cutting and cutting of acrylic and aluminum-plastic plates?

- Acrylic comes from English Acrylic, generic name for Acrylic acrylic and methacrylic acids chemicals. Including monomers, plates, aggregates, resin and composite material, acrylic acid methyl ester by methyl monomer (MMA) polymerization, namely polymethylmethacrylate (PMMA) organic glass plate, "organic glass" from the name "Oroglas" (a PMMA), from the "Organic Glass" (organic glass).

- Q:What is the raw material of glass made of?

- The glass raw materials used for the natural ore, so the manufacture of glass, first of all to all kinds of ore crushing, processing into powder, then according to the glass component, made with the material into the glass melting furnace for melting glass forming liquid. Qualified glass flows through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q:Long plastic soft glass is a food grade raw materials?

- The normal use of the family (including the dining table) is entirely without question

1. Manufacturer Overview |

|

|---|---|

| Location | Hunan,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | Southeast Asia;Mid-East |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | 9333,333 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Offline Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords