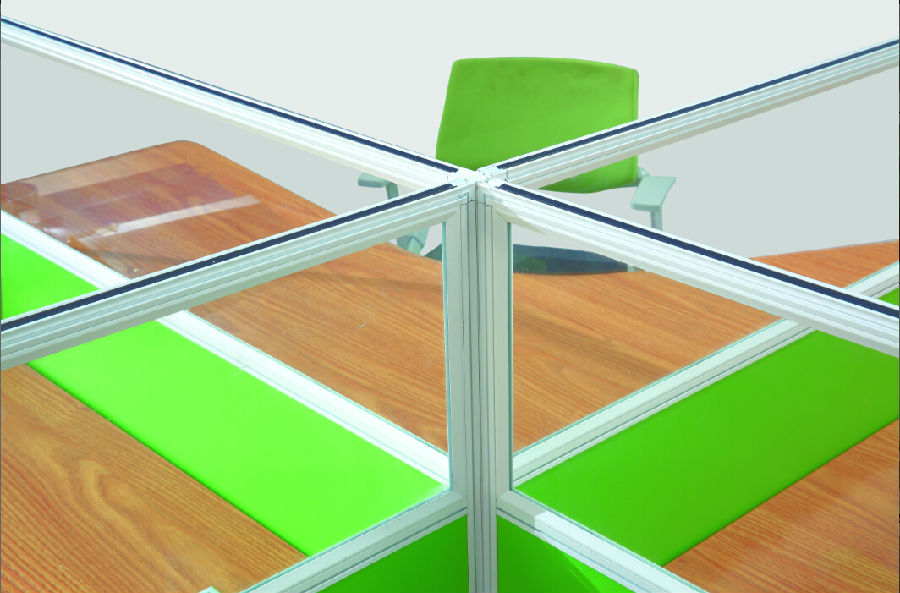

Office Table/Desk Hight Quality Wood MDF Melamine/Glass CN688 S

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Type: | Office Furniture | Specific Use: | Office Table | Wood Style: | Metal,MDF,Melamine |

| Certification | ISO9001 Quality & Enviroment | Size | 2800*2800*1050 | Advantages | Attractive Design ,Competitive Price |

| Assembling Guide | Available | customization: | Yes | Specific Uses | Office Desk ,Executive Desk |

| MOQ | 5 sets | Payment Term | T/T,L/C | Delivery Time | 15-20 days |

We specialized in office desk and office seating .Our factory has been engaged in office furniture for more than 10 years. Our factory is well-known in the high quality and competitive price of our products. Therefore, we completed in specifications and win warm praise from customers. In addition, the design of our products is deft, modern and beautiful. There are many types and colors for your selection. Our goods are easy and simple to handle and durable in use.

Welcome any questions!

- Q:What is the difference between laminated lumber (LVL) and plywood (plywood)?

- LVL is also called "forward" plywood. Generally, the wood fibers of each floor are in the opposite direction. In this case, the consequent forces are relatively large. For structural problems, there are a few layers that will be horizontal, such as the two floor.

- Q:Building engineering wood plywood can turn over several times?

- Turnover four or five times, no more problems, pay attention to brushing, release oil protection, sporadic damaged replacement.

- Q:What is plywood?

- The symmetrical structure can reduce the variation of the plate, and the grain direction of the two table plates is consistent. The veneer is coated with a high strength adhesive and pressed at a certain temperature and pressure.

- Q:What are the differences in cost between bamboo plywood and plywood and their respective uses?

- Generally speaking, bamboo plywood is expensive and has high performance. If there are more turnover in high-rise buildings, bamboo plywood will be selected

- Q:The difference between plywood and plywood

- Multilayer board is one of the common materials used in furniture processing enterprises. It is a kind of artificial board. A sheet of plywood usually glued together in a direction perpendicular to the direction of the adjacent layers of wood; usually the panels and inner panels are symmetrically arranged on either side of the center plate or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three commonly used plywood, plywood, multilayer board. Multi layer board can improve wood utilization rate, and it is a main way to save wood. It can also be used as aircraft, ship, train, automobile, building and packing box, etc..Multilayer board, also call three plywood and three plywood, the number of layers is different, the name is different. According to the thickness of 3-9 cm, you can also call 3-9 PCT plate. Its quality depends mainly on raw materials, Liu Anxin, each 1.2m.4m board price of 10-20 yuan. And peach blossom and yang wood will be cheaper.

- Q:What is a high pressure rubber sheet?

- High voltage rubber sheet is the abbreviation of insulated rubber sheet, and it has larger volume resistivity and electric breakdown resistance.

- Q:How long will it take for plywood to be free of formaldehyde?

- Plywood products emit a small amount of formaldehyde. New products produce the most formaldehyde, and the longer they use, the less they taste. But it takes years to evaporate completely.Removal of formaldehyde by ventilation:Through the circulation of indoor air, it can reduce the harmful substances in the indoor air, thus reducing the harm of such substances. In winter, people often close doors and windows, indoor and outdoor air can not flow, not only the content of formaldehyde in indoor air will increase, radon will continue to accumulate, and even reach a very high concentration.

- Q:Do you need a composite board or a splint for the new wardrobe?

- Plywood, also known as plywood, the line is commonly known as fine core board. Made of three or more layers of a single sheet of a millimeter thick veneer or glued. Handmade furniture is the most commonly used materials. A metal splint is commonly used on railroad tracks, commonly known as the fish plate, also known as the plywood.

- Q:What is the use of plywood in decoration engineering?

- Plywood is generally applied to situations where material strength and stability are relatively high. For example: Yunshan plywood is a soft Murray plywood, it can be used as houses, floors, walls and ceiling, covered with film can also be sprayed paint. The birch plywood with high hardness, film performance, can be installed directly, it can be used as concrete frame structure and floor formwork, container and other needs to do by the gravity of buildings and factory floor, scaffolding, do do LNG transportation isolation box etc..

- Q:About up to the use of modified rubber sheet!

- The price is almost the same, there is nothing particularly worthy of recommendation. Play mode, Qu Feng Tang, Shangzhi toys, roaming model, Qu Feng Tang, the KING model, they generally have a sheet, you see what love style!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Office Table/Desk Hight Quality Wood MDF Melamine/Glass CN688 S

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products