Office Furniture Commerical Desk/Table Solid Wood CMAX-BG054

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Office Furniture – Solid Wood Commercial Desk CMAX-BG054

Description of Office Furniture Commerical Desk/Table CMAX-BG054:

Type: | Office Furniture | Use: | Office Desk | Style: | Commercial Desk |

Material: | MDF/MFC, Melamine | Folding: | No | Color: | All Colors Available |

Volume: | 0.18 m³ | Customization: | Yes | Model: | CMAX-BG054 |

MOQ: | 20 Sets | Warranty: | 2 years | Use: | Commercial Furniture, office desk, office furniture |

We specialized in office desks and office seating. Our factory has been engaged in office furniture for more than 10 years and our factory is well-known for the high quality and competitive prices of our products. Our factory is well-known for the high quality and competitive prices of our products. We have won the praise of customers.

There are many types and colors to choose from. Our goods are easy and simple to handle and durable in use. Whether you need an office chair or modular furniture, we offer the service, experience and attention you deserve – no matter how big or small the job. Your satisfaction is our goal, that's why we only supply furniture from top brands! From workstations to cubicles, we have them all.

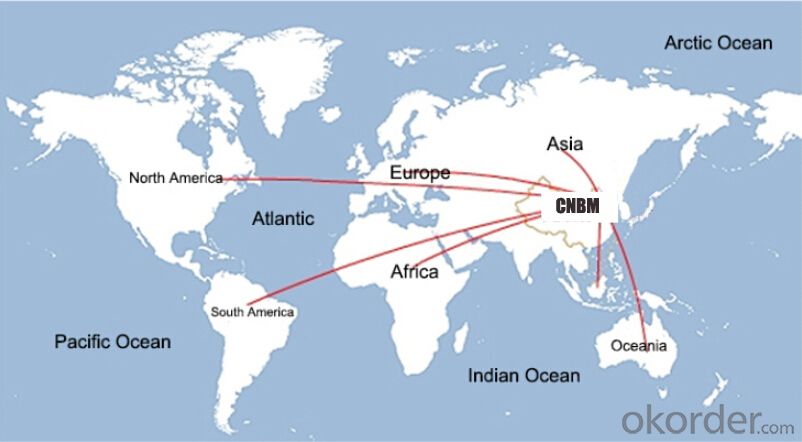

CNBM have a team of friendly and knowledgeable office Furniture and industrial furniture specialists who cater to our clientele looking for complete office fit outs.

We welcome any questions!

CMAX-BG054

1. Features of Office Furniture Commerical Desk/Table CMAX-BG054

1) Material: PU, PVC and fabric available

2) Height is adjustable

3) Rotation to 360°

4) Slide freely with wheels

5) Designs and patterns available upon request

6) Different colors are available

7) Elegant design, excellent workmanship

8) Height of seat and backrest adjustable

9) Seat pad thickness and backrest adequate

2. Quality Control of Office Furniture Commerical Desk/Table CMAX-BG054

1) Each product is checked & cleaned before packaging

2) We do our best to resolve problems when they occur

3) Every step of production is carefully inspected by our professional QC team to ensure the quality of our products

CMAX-BG054

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG059

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG062

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG057

1800*1900*760

2000*2000*760

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30%T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

- Q:Do you make furniture, carpentry or plywood? Which one is more expensive?

- The plywood formaldehyde wood board is more than 2, but has the best technology on the plywood formaldehyde, make the effect, especially the edge look good, and not to brush paint, short time limit, you do when manufacturers custom-made hydropower, hydropower well directly on-site installation of furniture, save a long time this woodworking process. If high, better paint what.

- Q:Please master, simple and easy to tell me what is: plywood, composite board, the kind of wood powder pressed into what the board? What are their characteristics, please?

- The composite board is bonded with several boards, including plywood + MDF, plywood + decorative panel, MDF + melamine board, MDF + MDF and so on

- Q:What is bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material.

- Q:What is plywood?

- Usually with phenolic resin, urea formaldehyde resin and melamine adhesive. Plywood can be used instead of boards, because plywood has a strong resistance to rupture, shrinkage, distortion and high strength. And plywood and solid wood compared to have larger size range, higher utilization rate and lower cost, so in building, decoration, furniture, shipbuilding and so on, there are many applications.

- Q:What is the difference between building formwork and bamboo plywood?

- There are many kinds of building formwork: wooden formwork, steel template and so on. Bamboo plywood can be used as a building membrane. It is just one of the building blocks

- Q:Excuse me: is there a rubber board in the building material market that can replace glass instead of glass?

- You can use the PC boardPC board is a kind of high quality sheet made of polycarbonate, which is made of CO extrusion technology CO-EXTRUSION. Because of its surface covered with a high concentration of UV absorbers, in addition to anti UV characteristics, and can maintain long-term weather resistance, never fade. The PC board connection can be connected by special glue and effectively leak proof. The PC board generally refers to the PC sun board, the PC endurance board and the PC diffuser board, the PC lighting board. Product series are: PC plastic sheet, PC special plate, PC injection molding products, PC plastic bending forming, PC equipment cover, PC electronic and electrical enclosures, PC taxi protection column, PC explosion-proof shield, PC advertising board and so on.

- Q:What are the common thickness of bamboo plywood?

- Because of the high hardness, bending resistance and compressive resistance of bamboo plywood, steel formwork has been replaced in many use areas. Because bamboo is easy to cultivate, quick forest trees, three to five years will be cut down, can replace wood, therefore, the State Forestry Department policy supports the development of wood-based panels with bamboo as the main materials, has replaced the use of wood plates in a lot of places

- Q:What are the common quality defects of plywood?

- The warpage of plywood is due to the internal stress of plywood. The reason is that the moisture content of the back surface of the sheet is inconsistent, the single board collocation of different tree species is not reasonable, the single plate has twisted grain, the temperature of the individual hot pressing plate is not enough, and the stacking of the plates is unequal.

- Q:Is the wardrobe made of rubber strong?

- The plywood is logs into veneer or by wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.Advantage:According to the weight, light, clear lines, insulation, strength, not easy to deformation.It is convenient to construct and should not be warped and warped. The tensile strength of the transverse stripes is good.Shortcoming:In accordance with the general high cost.

- Q:Do you need a composite board or a splint for the new wardrobe?

- Plywood, also known as plywood, the line is commonly known as fine core board. Made of three or more layers of a single sheet of a millimeter thick veneer or glued. Handmade furniture is the most commonly used materials. A metal splint is commonly used on railroad tracks, commonly known as the fish plate, also known as the plywood.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG054

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords