Office Furniture Commerical Desk/Table Solid Wood CMAX-BG044

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: | Office Furniture | Specific Use: | Office desk | Style: | Commerical Desk |

Material: | MDF/MFC,Melamine | Folded: | No | Color | All color are available |

Volume: | 0.18 m3 | customization: | Yes | Model | CMAX-BG044 |

MOQ | 20 sets | Warranty | 2 years | General Use: | Commercial Furniture,office desk,office furniture,for executives/directors/presidents |

We specialized in office desk and office seating .

Our factory has been engaged in office furnitur e for more than 10 years.

Our factory is wellknown in the high quality and competitive price of our products.

Therefore, we completed in specifications and win warm praise from customers.

In addition, the design of our products is deft, modern and beautiful.

There are many types and colors for your selection.

Our goods are easy and simple to handle and durable in use.

Whether you need 1 office chair or big modular furniture, we offer the service, experience and attention you deserve -no matter how big or small the job is.

Your satisfaction is our goal, that's why we only supply furniture from top brands!

From workstations to cubicles, we have them all.

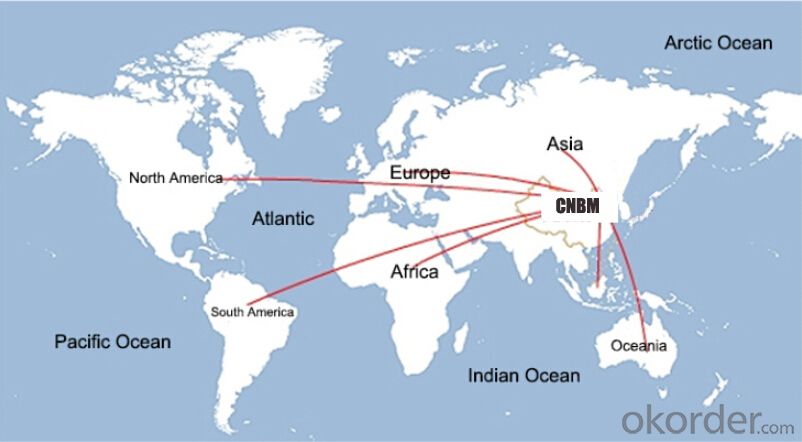

CNBM have a team of friendly and knowledgeable office Furniture and industrial furniture specialists with a specialists division who cater to our clientele who are looking for complete Office fitouts. At ROF we supply you more then just the chair or desks for your new working space, we create engaging and fresh office fitouts using our extensive range of Australia's best designs and qualities of office Furniture and industrial furniture.

Welcome any questions!

CMAX-BG044

1. Features

1) Material: PU, PVC and fabric available

2) Height is adjustable

3) Rotary max. to 360

4) Slide freely with wheels

5) Designs and Patterns available upon requests

6) Different colors are available

7) Elegant design, excellent workmanship

8) Height of the seat and backrest are suitable

9) The pad thickness of the seat and backrest are suitable

2. Quality Control

1) Every product quality will be checked & cleaned before packing

2) We will try our best to help clients when problems occurred

3) Every step of production is carefully inspected by our professional QC clerk to ensure the quality of our products

CMAX-BG065

2800*1400*1050

CMAX-BG068

2800*2800*1050

CMAX-BG044

1200*1400 (one seat)

CMAX-BG045

1200*1400 (one seat)

FAQ

Why choose us?

1, Advantage: Directly manufacturing factory with competitive price and quality control, we check all material when we start to bulk productions.

2, Professional advice to help you purchase the products you wanted/

3, Professional export service team servers in the deal.

4, Customization service is available, OEM business is appreciated.

5, We will inspect and test all products material carefully to ensure no damage and lost.

6, The success of our cooperation can be guaranteed for our company is a credible and honest partner.

How about the quality ?

1.Our normal material of MDF and MFC is with E1 standard. All oil paint we use is enviropaints. All kinds of Certification is available.Besides all the material could be customized.

How about the payment term?

1.Usually 30%T/T in Advace, the balance before shippment. L/C at sight could also be accept.

Other payment term could be discussed with specific orders.

Can you give warranty of your products?

Yes, we can supply 2 years warranty for our normal items. For the overseas orders, please provided emails with details including pictures, we will send replacements (Such as castors, screws, plastic pad of base) at our cost to repair the chairs in some coming orders.

- Q:What is the difference between laminated lumber (LVL) and plywood (plywood)?

- Plywood PLYWOOD, usually refers to the adjacent layer of wood fiber in the way of crossing, in order to tension is even.

- Q:What's the difference between a plywood press and a panel press?

- Use: laminator series machines are suitable for neutral or small man-made board furniture factory two processing factory (professional veneer), used for hot pressing adhesive plates, partition, building furniture doors and in various wood-based panels: such as plywood, blockboard, particleboard, MDF surface pressing various decorative materials, decorative paper, decorative melamine cloth, fireproof board, metal foil, artificial and natural veneer, natural wood mosaic; single version can not be used for drying leveling, leveling, setting the wood color decoration.According to the above content, you can compare.

- Q:Which is the thickness of plywood and plywood?

- Plywood, also known as plywood, is a log by cooking, softening, along the rings cut into large slices, after drying, finishing, coating, and billet, hot pressing, saw edges. The number of wood chips should be odd number, and the time of gluing should be perpendicular to the fibers of adjacent wood pieces. The plywood can be divided into 4 grades, such as grade, first class, two, three and so on. Plywood specifications for long 2440mm, wide 1220mm, different specifications of plywood thickness is different, but generally are multiples of 3.

- Q:What is the difference between plywood and veneer?

- Which is better, eco board or plywood? Plywood can improve wood utilization, and it is a main way to save wood. They can also be used in aircraft, ships, trains, automobiles, buildings and packing boxes. Ecological plate as a new type of veneer and plywood making products (or Blockboard) of two kinds of plank function in saving the production process be made one, at the same time, increase the added value of products, saving labor costs and renovation costs for consumers, is leading the new trend of home decoration, currently on the market mainstream furniture are basically using melamine panels made of. A little is more important in ecological environmental protection level must be E0 or E1 can be called ecological board, not all can be called ecological plate plate.

- Q:Pressing process of plywood

- Plywood is one of the commonly used furniture materials. It is a kind of artificial board. A set of veneers usually glued together in a direction perpendicular to the direction of the adjacent layers of wood. Usually the table plate and the inner plate are symmetrically arranged on both sides of the central layer or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three commonly used plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood. They can also be used in aircraft, ships, trains, automobiles, buildings and packing boxes.

- Q:What is the thickness requirement of the insulation board in the distribution room?

- General appearance requirements:1, the insulation plate edge neat, no crack.2, bubble per square meter range, the area of less than 1 square centimeter of bubble may not exceed 5. The spacing between any two bubbles shall not be less than 40mm.3. The depth and length of the impurity shall not exceed 1/6 of the thickness of the insulating plate.

- Q:Will the steel formwork be replaced by bamboo plywood in future construction?

- A composite steel formwork has emerged, and four new technologies, such as steel instead of wood, have encouraged construction companies to use them, as well as sliding mode.

- Q:What is the density of the oil resistant rubber sheet?

- The best way is to take a sample test. Fluorine rubber biggest proportion, nitrile rubber minimum proportion, mixed rubber 1.0~1.2 between. Chloroprene rubber compound is around 1.3

- Q:Which is better, bamboo plywood or wood plywood?

- Wood formwork is suitable for small high-rise buildings and is usually decided by engineering. You can understand each one has his good points, specific central arrows, they are specialized in the production of building template factory. Hope to be of help to you

- Q:About up to the use of modified rubber sheet!

- You can buy Tamiya, also can buy domestic. TB also have that kind of division of all kinds of width, generally speaking, 1MM thickness board used the most frequently.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG044

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords