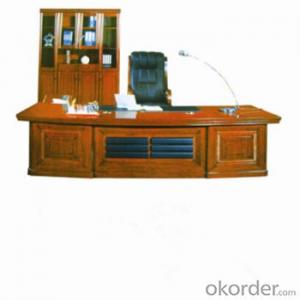

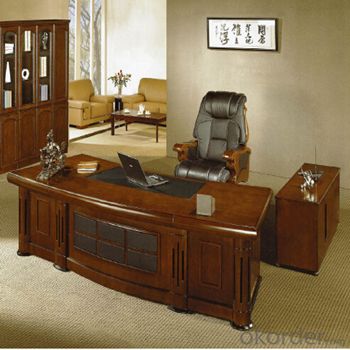

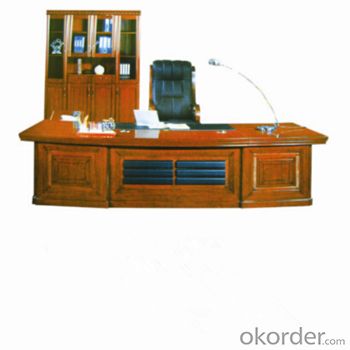

Office Boss Table with Excellent Surface Finishing

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Office Boss Table with Excellent Surface Finishing Description

We have 10 years experience in producing office furniture and provide all services for your import. This office boss table with Modern design is the newest design with optional colors. This boss table is anti-water, anti-dirty and anti-scratch. The boss table has a sturdy structure and excellent surface finishing.

Office Boss Table with Excellent Surface Finishing Characteristics

· Modern Design and optional colors

· High quality MDF, famous brand hardware

· Anti-water, anti-dirty and anti-scratch

Office Boss Table with Excellent Surface Finishing Image

Office Boss Table with Excellent Surface Finishing Specification

Item | Content |

Name | Furniture |

Item Type | Office table |

Item Description | Office boss table |

Size | 3600*1100*760 |

Color | Reddish, Walnut, Brown, Black |

Material | MDF+Veneer, MDF+Paper |

Frame | Wood |

MOQ | 20 sets |

Production Capacity | 5000 sets per months |

Product Features | Anti-water, Anti-dirty |

FAQ

Do you accept OEM/ODM?

Products can be made according to your requirements. ODM/OEM is welcomed.

What is the warranty?

We offer 2-5 years warranty replacement against manufacturer defect.

What is your advantage?

We have strict quality control department to ensure all the goods to be right & correct delivery to customers.

All of our products are environmentally friendly meet the international standard.

- Q:What's the difference between a plywood press and a panel press?

- Plywood hot press is one of the main equipment for plywood production process, is used for hot pressing of glue combined slab equipment, properties of different varieties of plywood press have different requirements: general aviation manufacturing plywood, plywood, veneer, wood plastic laminated plastic board, plywood vessel pressure required in turn increase. Plywood hot press according to the operation mode, divided into two types of cycles and continuous, the domestic regular is a cyclical multi-layer hot press. It consists of three parts: press machine body, control drive part (hydraulic system and electric control system), heating system.

- Q:Plywood with natural red oak bark at the end of what is the reason?

- Hello friend。 There are two possibilities. The first wood veneer is too thin. Second red like wood, rough wood a little.

- Q:What kind of glue do you want to make the plywood?

- Urea formaldehyde resin has low cost, light color, high hardness, oil resistance, mildew resistance, good insulation and temperature resistance, but its weather resistance and water resistance are poor. It is one of the thermosetting resins developed earlier. In 1924, the British developed melamine company, beginning in 1928, the sale of products, the mid 30s output reached thousand tons, in 80s the world's annual output has more than 1.5Mt.

- Q:How much is the wall of punched plywood one square metre?

- Light steel keel frame, plywood surface, single-sided 85 yuan / square, double-sided 115 yuan / square meter. Plywood is not suitable for partitions. One is the fear of water, water absorption will become uneven.

- Q:The difference between a plywood, a plywood, and a cover plate

- A building block is a variety of plywood classified according to usage, used for concrete construction, and is a kind of plywood.Most of the building blocks are made of plywood.

- Q:What kind of glue does bamboo plywood use in general?

- The four roller coating machine soluble phenolic resin on bamboo roller gelatinize for water, 300-350g/ square meters (double). Adhesive can be added 1%--3% flour, soy flour and other fillers. The filling agent causes the bamboo sheet to form a gum film on the surface after gluing, which is difficult to produce flowing glue when hot pressing, and the brittleness of the adhesive layer can be improved after curing.

- Q:Will the ceiling be made of plywood or plasterboard?

- Ceiling plywood, I still heard for the first time, construction difficult, high cost.See where you use the ceiling, bathroom, kitchen can choose finished integrated ceiling, relatively high cost, plastic gusset plate is cheaper,PVC products on the market, plastic steel ceiling material is also a lot.

- Q:Multi ply board (plywood), carpentry board, that suitable for wardrobe?

- The multilayer board is also sometimes referred to as plywood, blockboard and he in the manufacturing method, material selection and other aspects are similar, and the multilayer joinery board is composed of several layers of sheet, but unlike Blockboard is not necessarily the central multilayer board three layer, and the thickness of each layer divided multilayer board the. The multilayer plate has the advantages of good structural strength, good stability, unfavorable deformation and strong environmental protection. The utility model is mainly used for the decoration of the bottom plate of the decorative panel and the wooden board of the panel furniture.

- Q:Desulfurization absorption tower anticorrosive lining glue, specifications have stipulated, rubber board need sampling?

- Mortar besmear after airing, Anshan anticorrosive lining glue factory, can undertake joint operation. This process should pay attention to the following points: 1, handle 2, hanging mortar flow handle rubber edge 3, to ensure a smooth and fully fit rubber lining 4, handle groove, corner parts 5, * * * the lining for the drum bubble, the auscultation stick for confirmation, such as hollowing is excluded by the puncture foaming rolling, and then use the iron sheet surface will be eradicated, desulfurization absorption tower anticorrosive rubber lining manufacturers, and then by shovel out the same area after the mortar lining layer dry well, finally will repair in the whole pressure plate branded vouchers, makes vulcanization after bubbling to reduce as far as possible, to ensure the quality of rubber lining equipment.

- Q:The difference between wood cored plywood

- Woodworking boards are made of plywood, but plywood is not necessarily a wood board. Plywood is the use of wood glue will be laminated or more pieces of wood together. The board is the number of pieces of wood glued together, then both sides of paste wood leather.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Office Boss Table with Excellent Surface Finishing

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords