OEM A4 Paper 80GSM, Original Paper, 100% wood

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

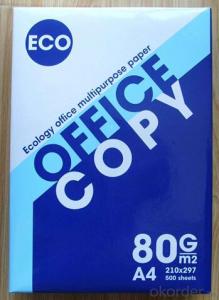

Item Name: A4 paper Material: 100% Wood Pulp

Size: A4, A3, 8.5*11'', 8.5*14'', 8.5*17''

Base Weight: 80gsm, 75gsm, 70gsm

Brightness: 102-104%, 98-100%, 94-96%

Whiteness: CIE 140-167

Moisture Content: 4.5-5.5%

Our Services

1-OEM Service

2-Can Do export by ourself

3-Shipping advantage, good price

Packaging & Shipping

Packing: 500 sheets per ream, 5 reams per carton

80gsm: 8000 reams /20'fcl

75gsm: 8200 reams/20'fcl

70gsm: 8400 reams/20'fcl

Company Information

Payment: 30% TT in advance, balance against the copy of B/L

Delivery; After get deposite within 10 days

MOQ: 1x20'fcl

Origin: Made In China

How to store:

1). Store in a dry, cool dark place, avoid exposing to the place of high temperature,

High humidity and sunlight or light irradiate directly;

2). Do not store with chemicals;

3). Avoid the strong extrusion, friction and scratching;

4). This product is a one-time use only and destroyed after use;

| Item | Copy Paper a4 paper 70g 80g with high quality low price |

| M aterial | 100% virgin pulp |

| size | A4 size , 210*297mm; |

| B ase weight | 70, 75,80 |

| Whiteness | 110% |

| Key performance | 2. Quality: Imported 100% Virgin Wood Pulp 3. Whiteness = 110% , White 4. Capability: High Speed Copying100ppm, Laser 5. Capable, Inkjet Capable, Fax Capable. 6. Thickness: 103-110 um 7. Surface roughness TS ml/ min: 75-175 8. Surface roughness BS ml/ min: 100-200 9. Bending stiffness MD: > 110 Mn 10. Bending stiffness CD: > 50 Mn. 11. CIE whiteness: 148-152 12. Cobb Test: 27-33 g/ m2 27-33 |

| specification | ItemCopy Paper a4 paper 70g 80g with high quality low priceMaterial100 % virgin wood pulpSizeA4 : 210*297mmBase Weight80gsm,75gsm,70gsmWhiteness110%,natural whitePacking500 sheets per ream,10 reams per carton(box)Load Qty(20ft)GSMA480gsm8000 reams75gsm8200 reams70gsm8400 reamsKey performanceNo jam in photocopy machineNo double feedStay flat after copyingLeave no dust in the copy-machineNice appearance-white and cleanNice touch-smooth and bulkyNo see through-print both sidesBeen developed for: Photocopy Machines, Laser Printers, Ink-jet Printers, Fax Machines |

- Q:How big is the 8.5 Inch x 11 inch paper?

- Don't listen to that nonsense. This is American standard writing paper. The size is 28cm*21.5cm, and the model is F4

- Q:What is a steamer paper?

- Of course, the premise of the cloth must be clean. Both before and after use should be cleaned, so that the body will not cause harm.

- Q:What's the advantage of paper barbecue?

- The advantage of paper barbecue is to avoid food coke, but it can also replenish the water loss of food. It can not only drain the surplus oil of food itself, but also maintain the nutrients inside the food. Traditional barbecue with carbon, fire and gas stoves can easily damage the protein in the food itself, and can also cause harmful substances when accidentally burnt. The paper on the benefits of no open flame barbecue, double heating, paper baked food can help retain moisture food itself, all kinds of sauce with a special tone, taste more tender! The bottom of the oven baked with a single small, can be fried egg, fried steak, fried pork, seafood, fresh color, fragrance.

- Q:Carton carton k535k is different from K=K?

- A=B is a facial tissue, A paper, tissue paper is B paper, A paper, B paper is divided into several kinds, generally we are to rupture strength to require manufacturers,.A=B than B=C material better. Is the five layer double pit paper, K3K is three single layer of paper

- Q:What are the conditions for the production of cardboard?

- Pit box material, facial tissue, usually with card box like material, that is, can do card box material can be used as pit box of facial tissue material, facial tissue is mainly used for printing graphic material. The pit is not used for printing paper, it is a non printing surface on the cardboard, glue and cardboard glued together. The function of pit paper is to improve the physical properties of the color box, such as explosion protection, collision avoidance and impact resistance, so as to protect the product and prevent the product from being damaged during the course of transportation and storage. The pit paper is divided into coarse pits and fine pits according to the thickness of the pits. According to the color of the pit paper, it is also divided into white, yellow and color, with corresponding numbers or letters indicating different pits, thickness, quality grade or color. For example, W9 stands for white fine pits, and A3 stands for yellow pits. The production process of facial tissue is nothing different from that of the card box. The difference between the pit and the paper box and the card is that the pit paper and the surface paper are mounted together. That is to say, more than one laminating process.

- Q:What is the three pit carton?

- Corrugated paperboard is made of adhesive paper, paper, core paper and corrugated corrugated paper. According to the demand of commodity packaging, corrugated paperboard can be processed into single-sided corrugated paperboard, three ply corrugated paperboard, five ply, seven ply and eleven ply corrugated paperboard.

- Q:What is industrial cardboard?

- Cardboard, cardboard, paper board machine making process, cylinder board machine and the characteristics of the new board forming device, cardboard, cardboard press plate press dehydration, continuous board machine press section, press felt, cardboard, cardboard drying, drying plate continuous dryer section board machine the board, complete grooming, board adjustment, light pressure, the cardboard cardboard cardboard rewinding, cutting and sorting, cardboard packaging, insulation board production, thick insulation board, insulation board, thin insulating board performance factors, insulation molding type with the manufacturing and processing technology and equipment, coated cardboard, cardboard, cardboard boxes, type detector steel liner board, plastic board, plywood, multilayer board manufacturing bone board, multilayer board, forming device, dehydration The finishing, interlaminar strength, board performance, construction industry, gypsum board, cardboard production of felt and other industrial cardboard production, jacquard cardboard, cardboard, cardboard, filter tube waterproof cardboard, cardboard, cardboard, suitcase standard cardboard, cardboard, shoe accordion bellows, gray cardboard, cardboard, cardboard envelope the partition board

- Q:What kind of paper do you use for gouache?

- Then I just use gouache paper, gouache watercolor paper texture is slightly thin, absorbent and texture is relatively low, but also a little cheaper than watercolor paper.

- Q:The difference between heat sensitive paper and plain paper

- These are two different kinds of paperHeat sensitive paper simply means that the paper is heated through the printer to form dots and finally to form words or pictures

- Q:What's the price of the double grey cardboard?

- From the perspective of raw materials, the gray cardboard of the pulp is more than double ash, fiber length should be long, so full of gray paper more hard, higher stiffness, surface more smooth, it is suitable for high-grade, high stiffness products. For example, high-end jewelry box, wine box.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

OEM A4 Paper 80GSM, Original Paper, 100% wood

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products