Nonwoven Geotextile Membrane price Polyester Needle Punched

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

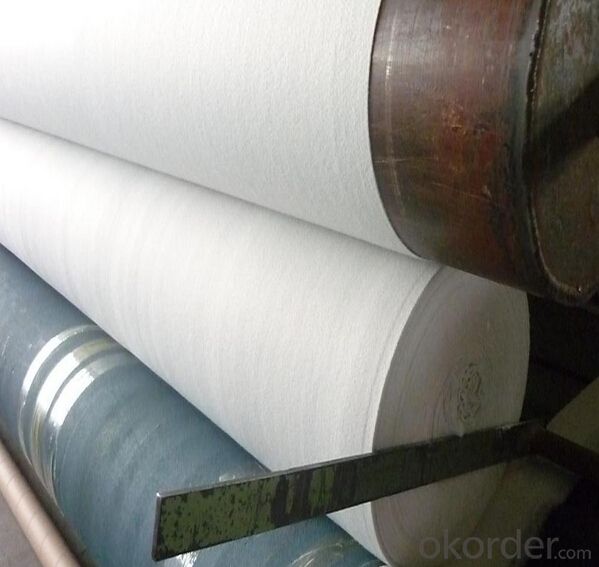

Nonwoven Geotextile Membrane price Polyester Needle Punched

Desciriptions:

Geotextile can avoid the sharps objects damage to pipeline and others buried underground.

Geotextile can reinforce the roadbed,slow down the pavement fracture.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Wide-width rolls

Quality Certified

Proven for use in Main Roads works

Large range to suit the application

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:GB waterproof geotextile what price

- GB waterproof geotextile details please see

- Q:Are geotextiles suitable for use in geogrid reinforced soil slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced soil slopes. Geotextiles provide additional reinforcement and stability to the soil slopes when used in conjunction with geogrids. They help to distribute loads, reduce soil erosion, and improve drainage, which ultimately enhances the performance and longevity of the reinforced slope system.

- Q:What are the factors to consider when designing geotextile-reinforced walls?

- When designing geotextile-reinforced walls, there are several factors that need to be considered. Firstly, the type and strength of the geotextile material must be chosen carefully to ensure it can effectively withstand the loads and stresses imposed by the wall's design and the soil conditions. Secondly, the wall's geometry and dimensions need to be determined, taking into account factors such as the height of the wall, the slope angle, and the overall stability requirements. Thirdly, the soil conditions and properties at the site should be thoroughly examined to understand their impact on the wall's design. This includes factors such as soil type, compaction level, moisture content, and shear strength. Additionally, the design should account for potential environmental factors such as rainfall, groundwater levels, and potential surcharges or seismic activity that could affect the stability of the wall. Furthermore, the construction and installation process needs to be considered, ensuring that the geotextile reinforcement is properly installed and securely connected to the wall structure. Overall, a comprehensive analysis of these factors is necessary to ensure the successful design and construction of geotextile-reinforced walls that are safe, durable, and effective in their intended purpose.

- Q:Can geotextiles be used in stormwater detention systems?

- Yes, geotextiles can be used in stormwater detention systems. Geotextiles are commonly used in these systems to separate the soil and aggregate layers, to provide filtration and drainage, and to enhance the overall stability and performance of the system.

- Q:Can geotextiles be used in water retention projects?

- Yes, geotextiles can be used in water retention projects. Geotextiles are often employed as an effective solution for erosion control, filtration, and separation of materials in water-related construction projects. They can help retain water by preventing soil erosion and enhancing water infiltration, making them a valuable component in water retention projects.

- Q:Can geotextiles be used in railway projects?

- Yes, geotextiles can be used in railway projects. Geotextiles are commonly utilized in railway construction and maintenance for various applications such as separation, filtration, drainage, and reinforcement. They can help improve the stability, strength, and longevity of railway tracks, reduce maintenance costs, and enhance overall performance.

- Q:Geotextile construction requirements of the use of adhesive specifications

- Hello, geotextile construction is very simple, laying with less cutting, less overlap for the principle. Take the head set aside about 25 cm. Using double take the head, sew two lines. This is in principle to ask this, the general construction can not do so carefully. Huazhi geotechnical materials manufacturers to answer, need to talk.

- Q:Roof garden pool at the bottom with pebbles, pebbles above with geotextile, geotextile above the soil

- Geotextile laying on the soil can be, goose soft stone has replaced the effectiveness of the drainage board. Geotextile play a filtering effect, the excess water through the cloth, go through goose soft stone flow. Soil is geotextile interception, will not be lost, plug the drain, Huazhi geotextile material manufacturers.

- Q:What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as the material type, weight, permeability, and strength. The geotextiles should be made of durable and non-biodegradable materials such as polypropylene or polyester. The weight of the geotextiles is generally specified in terms of grams per square meter (gsm), with heavier weights often preferred for better performance. Permeability is an important factor, and geotextiles with high permeability allow for efficient water flow while preventing soil erosion. Additionally, the geotextiles should possess adequate strength to withstand installation stresses and ongoing loadings. Overall, the specifications ensure that the geotextiles effectively separate, filter, and reinforce the soil in drainage projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Nonwoven Geotextile Membrane price Polyester Needle Punched

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords