Nonwoven Fabric For Wet Wipes, Spunlace Nonwoven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

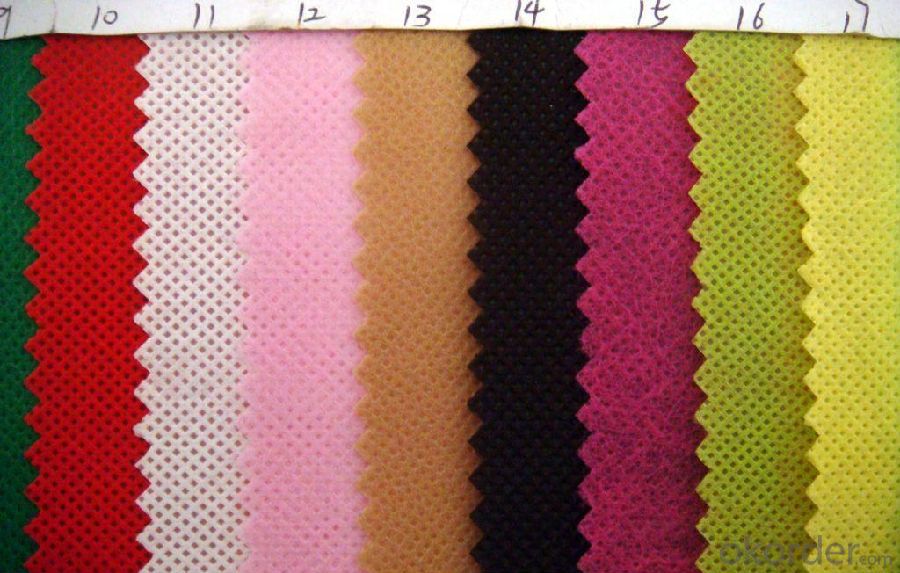

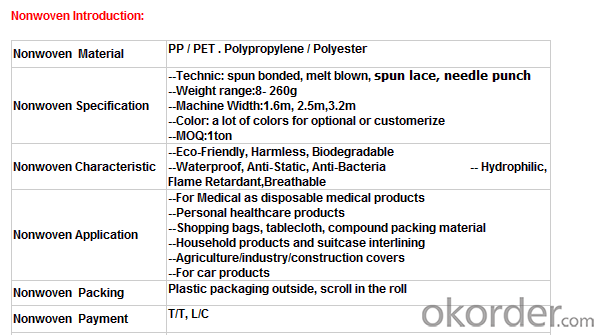

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q:The development of wool in Australia is not developed.

- High-tech industry in recent years has developed rapidly, in the international market competitiveness has improved. The share of services in the gross domestic product (GDP) has increased, and now it has reached about 70%.

- Q:What is the anti-perspiration finishing of textiles?

- At present, the domestic can do single-parent single-finishing manufacturers have a lot, but do not much anti-perspiration finishing manufacturers, because of its high technical requirements, many manufacturers put anti-perspiration requirements made of single-parent single fabric, from In a sense is to complete the customer's request,

- Q:From the yarn to the finished textile fabric production process is how

- Nylon is the most important engineering plastics, production in the top five general engineering plastics in the first place. Nylon [1], is a polyamide fiber (nylon) is a saying can be made of long fiber or staple fiber. Mercerized cotton: in accordance with the two mercerizing process division, mercerized cotton can be either through the yarn mercerized process of cotton yarn processing, but also refers to the fabric after mercerized cotton fabric

- Q:"Textile color standard system"

- The dye molecules and heavy metal ions are likely to be absorbed by the skin and endanger the health of human skin, on the other hand will affect the other clothing worn on the body was stained, or with other clothes when washing dirty other clothing The

- Q:Textile industry belongs to the first few industries

- The first industry in the "classification of national economic industry" (GB / T 4754-2002), a category that is Class A, including agriculture, forestry, animal husbandry, fisheries and agriculture, forestry, animal husbandry, fishing services a total of five categories; Mining and salt industry into the secondary industry.

- Q:What is the textile technology profession now?

- Spinning equipment and technology; the main introduction of the selection of spinning raw materials, cotton spinning process (open, carding, combing, parallel, roving, spun yarn and post-processing) equipment used in the main institutions and functions, Product quality of the advanced experience and the main technology, the typical equipment of the transmission and process calculations; on the basis of the introduction of wool technology, equipment, and a brief introduction to new spinning

- Q:What is the role of textile degreasing in life?

- Textile degreasing agent in the use of textile processing is unusually common, and the use of the remaining additives is definitely more difficult to practice in terms of light. Therefore, the textile degreasing agent in the textile auxiliaries in this family is particularly popular

- Q:Classification of textile materials

- According to the definition of textile materials, the contents of textile materials, including fiber and fiber aggregates. Fibers are the basic unit of textile materials. The origin, composition, preparation, morphology, performance of the fiber is extremely rich and complex and directly affects its composition

- Q:What is the amount of alkali in the textile mill

- Diminishing, as the name implies, is to reduce the amount of something. Here refers to the polyester fabric on the corrosion treatment, the polyester fiber surface corrosion does not affect the performance of the groove, in order to achieve a soft, breathable good purpose.

- Q:What are the processes of dyeing and finishing of textiles?

- Different raw materials processing process is not exactly the same, the specific operation of specific raw materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Nonwoven Fabric For Wet Wipes, Spunlace Nonwoven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords