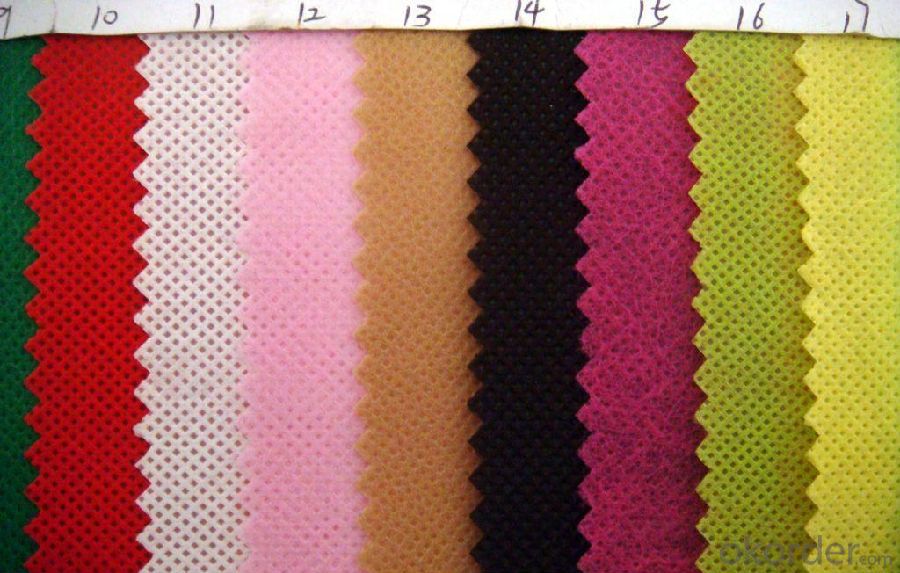

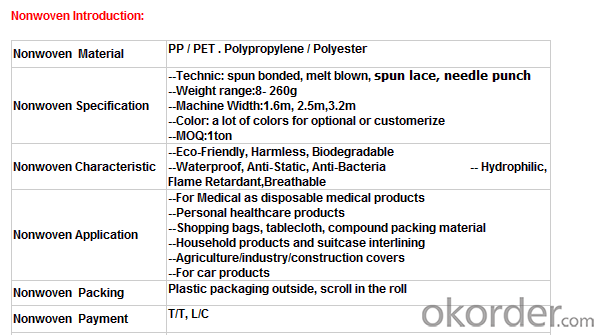

Non-woven Nonwoven Fabric, PP Nonwoven Fabric, PP Spunbond Nonwoven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q:Textile printing and dyeing process which

- Dyeing is a more complex process, different quality of cloth dyeing process is different, cotton, polyester cotton, nylon, polyester, chemical fiber products, blended products and so on. Some use of pad dyeing, roll dyeing, and some must use high temperature and high pressure dyeing, and some only once, and some to color several times.

- Q:The weight of the textile fabric

- Raw material costs, raw material costs = yarn per yarn X yarn price, how to calculate the amount of yarn per meter? We put all the fabrics into non-elastic fabric, weft fabric, four-sided fabric to show one by one.

- Q:What is the use of polyurethane TPU hot melt adhesives in textiles?

- Carpet rubber adhesive with the basic material for the ethylene and other olefinic monomer copolymer, such as ethylene - vinyl acetate copolymer, ethylene acrylate copolymer. The vast majority of cases are the use of ethylene. Vinyl acetate copolymer (EvA).

- Q:What is eco textile?

- Consumption ecology - from the perspective of human ecology, the study of the residual toxic substances in textiles on human health; 3. dealing with ecology - from the perspective of ecological treatment, control of textile recyclable, natural degradation, waste treatment Its release of toxic substances harmless to the environment.

- Q:Why can the oil industry be used as raw materials for the textile industry?

- Commonly used textile industry raw materials are: polyester: polystyrene dicarboxylate; nylon: polyamide fiber; polypropylene: acrylic fiber; acrylic: polyacrylonitrile fiber; polyvinyl chloride: polyvinyl chloride; vinylon: polyvinyl alcohol shrink Aldehyde fiber; aramid: poly (p-phenylene terephthalamide).

- Q:What is the textile technology profession now?

- Dyeing and finishing technology; this course more systematically describe the various textile fiber products in the dyeing and finishing of the basic process and process conditions, and the principles and commonly used machinery and equipment for a brief introduction, so that beginners master the basic knowledge of dyeing and finishing The

- Q:What is the meaning of TOP in the textile industry?

- 50D T + 20D OP, 50D polyester filament + 20D spandex, OP is the meaning of spandex. T is polyester.

- Q:What is the "gold and silver wire" used in the textile industry?

- Rhitherigma compositions. Refithers. Find Results Avithers.ithers. Rhithericals.s.ithers. Rhithergs.ithers. Rhithergs.ithers. Rhithergs.ithers. Rhithergs.itheromenigma Rhithers. Rhithergs.ithers. Rhithergs.itheromenigma Rhithers. Rhithergs.ithers. Rhithergs.omeniculates Rhithergs.ithers. Rhithergs.omeniculates Rhithergitherigmaither Rhitherd Rh to Rhomenacheither Rhomenigma Rhitheric roundsy Avg -

- Q:What is the anti-perspiration finishing of textiles?

- Many manufacturers put the anti-perspiration requirements made single-parent single defense fabric, in a sense is to complete the customer's request, but the requirements of high customers, only single-parent single effect is unable to meet the requirements, be sure to do Perspiration requirements.Hope to help you, if you want to do further understanding, see my account name and contact me

- Q:What is the step in the textile fabric

- Pre-fully assess the potential occurrence of the problem in the work, the corresponding efforts to strengthen the work, improve the fine pre-work to reduce or even eliminate the possibility of its occurrence. Not to find the problem for the purpose of pre-full prevention, work in the repeated excavation, timely processing and lessons learned, the future work methods and rules to further improve the party as a fundamental way.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-woven Nonwoven Fabric, PP Nonwoven Fabric, PP Spunbond Nonwoven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products