Non-woven High-Performance Geotextile Fabric for Railway-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

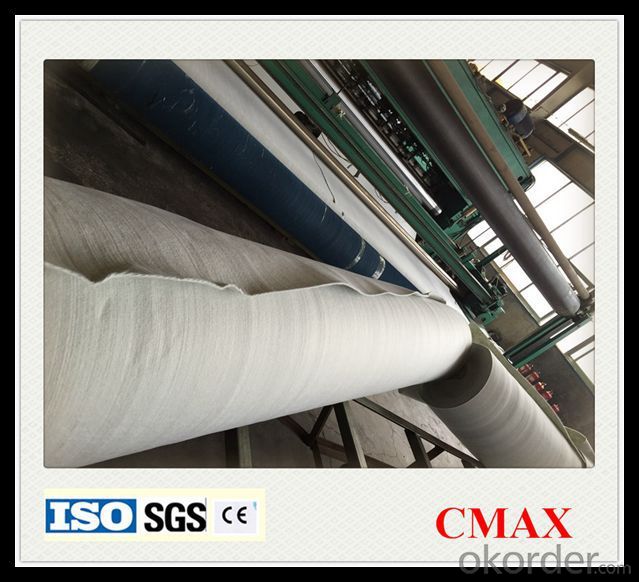

Non-woven (Filtration and Drainage Fabrics)

Needlepunched polypropylene fiber geotextiles utilized in site drainage, blanket drains

and pipe joint wrapping and erosion control under rip rap.

As a Separator is utilized amid the inappropriate and out of place material and good bag

filled with material, this practice will further help decrease the excavation deepness of

unsuitable or inappropriate sub-grade. It minimizes the cumulative width to even out and

alleviate the sub-grade. The non woven geo textile fabric preserves a consistent

settlement of the sub-grade and for this reason helps enhances the sub grade potency and

extends the working life of the system.

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:How do geotextiles aid in the reduction of frost heave?

- Geotextiles aid in the reduction of frost heave by providing a barrier that prevents the upward movement of moisture within the soil. This barrier minimizes the formation of ice lenses, which are a major cause of frost heave. Additionally, geotextiles help to distribute the load more evenly across the soil, reducing the pressure on the underlying layers and minimizing the potential for frost heave to occur.

- Q:How are geotextiles secured in place?

- Geotextiles are typically secured in place using various methods such as anchoring pins, stakes, or other mechanical devices that are driven into the ground. Additionally, they can also be secured using soil cover, rocks, or other heavy materials to prevent them from shifting or moving.

- Q:On the road where the laying of geotextiles should be how to shop

- Like roadbed fill, fill the junction and so on can be shop, a layer of a layer of shop, fixed good.

- Q:What are the different factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. These include the intended application or function of the geotextile, the site conditions and soil characteristics, the required strength and durability, the installation and maintenance requirements, and the cost-effectiveness of the geotextile. Additionally, factors such as compatibility with other materials, environmental considerations, and regulatory requirements may also need to be taken into account.

- Q:Can geotextiles be used in the protection of underground cables and pipes?

- Yes, geotextiles can be used in the protection of underground cables and pipes. Geotextiles act as a barrier between the cables/pipes and surrounding soil, preventing potential damage caused by abrasion, puncture, or chemical reactions. They help distribute loads and provide stability, improving the overall performance and lifespan of underground infrastructure.

- Q:Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

- Q:Detailing the geotextile standard which, how to apply their own

- Detailing the geotextile standard which, how to apply their own

- Q:What are the key considerations for geotextile installation in high wind areas?

- The key considerations for geotextile installation in high wind areas include selecting a high-strength geotextile material, ensuring proper anchoring and securing methods, evaluating the site's wind load potential, and implementing effective quality control measures to ensure the installation's durability and long-term performance.

- Q:300 grams of non-woven geotextile piercing strength is how much

- First of all, according to what you said 300g non-woven geotextile should be polyester staple fiber non-woven geotextile. Polyester staple fiber non - woven geotextile implementation of the national standard GB / T - 2008 standard. According to GB / T-2008 standard anti-puncture strength (standard is CBR burst strength) requirements, 300g national standard geotextile anti-piercing strength should be ≥ 1.5KN.

- Q:How do geotextiles contribute to green building certifications?

- Geotextiles contribute to green building certifications by providing sustainable and eco-friendly solutions for various construction applications. They can help improve stormwater management, erosion control, and soil stabilization, reducing the environmental impact of construction projects. By incorporating geotextiles in building designs, projects can meet the requirements of green building certifications that prioritize sustainable practices and materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-woven High-Performance Geotextile Fabric for Railway-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords