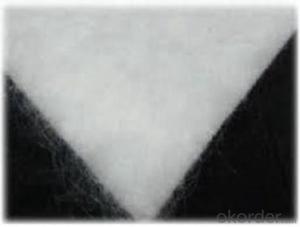

Non-woven Geotextile Price Reinforcement and Drainage-CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Geotextile Non woven

Filament geotextile non woven has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects

: Restaurant, hotel, home, supermarket,,theatre, Exhibition, KTV, PUB,Train,ship,car,etc.Weight: 200g/m2--800g/m2Width: 1m-4mLength: 30m-60mColor: Any colors available or customers colorsPacking: Transparent polybag or White PP woven bagTechnics: Needle punchded/non wovenProductivity: More than 10000 sqms/dayPlace of origin: Shandong, ChinaLoad quantity Around 4000-12000m2 in 1x20ft container,Around 17000-30000m2 in 1X40HQ containerMOQ: 3000 m2 of each colorDelivery time: Within 25-30 working days after receiving your advance moneyPayment term: T/T, L/C,D/PPort: Qingdao, China

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geotextiles be used in the construction of sports fields?

- Yes, geotextiles can be used in the construction of sports fields. Geotextiles are often used as a barrier between the soil and the playing surface to prevent weed growth, stabilize the soil, and improve drainage. They can also enhance the durability and longevity of the sports field by preventing soil erosion and reducing the risk of subsidence.

- Q:What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as material strength, permeability, durability, and resistance to UV degradation. The geotextiles used in these projects should have high tensile strength to withstand the forces exerted by waves and tides, as well as good permeability to allow for proper water drainage. They should also be resistant to chemicals and biological degradation, as well as have the ability to withstand harsh weather conditions. Additionally, they may need to meet specific standards or certifications set by regulatory bodies or project requirements.

- Q:How do geotextiles improve drainage systems?

- Geotextiles improve drainage systems by acting as a filter between the soil and the drainage material, preventing clogging and allowing water to flow freely. They also help in distributing the water evenly, reducing erosion, and enhancing the overall efficiency and longevity of the drainage system.

- Q:What are the benefits of using geotextiles in erosion control?

- Geotextiles offer several benefits in erosion control, including their ability to prevent soil erosion, stabilize slopes, and promote vegetation growth. They act as a barrier against water flow, reducing the impact of rainfall and preventing sediment runoff. Geotextiles also enhance soil reinforcement by distributing load and reducing soil movement. Furthermore, they allow for better filtration and drainage, improving water quality and reducing the risk of flooding. Overall, geotextiles provide cost-effective and environmentally friendly solutions for erosion control.

- Q:Will geotextiles generally use where?

- Geotextile applications (1) Reinforcement in backfill for retaining walls, or panels for anchoring retaining walls. Building a parcel or retaining bridge. (2) to reinforce the flexible road surface, repair the cracks on the road, to prevent the road reflection cracks. (3) to increase the stability of gravel slope and reinforced soil to prevent soil erosion and low temperature soil damage. (4) the separation between the road ballast and the roadbed, or the isolation between the roadbed and the soft foundation. (5) artificial fill, rock or material field and the isolation layer of the foundation, the separation between different frozen soil layer. Anti-filtration and reinforcement. (6) ash filter or tailings dam early upstream of the dam surface filter, retaining wall backfill drainage system filter layer. (7) drainage around the tube or gravel drainage ditch around the filter layer. (8) Water conservancy works in the wells, relief wells or diagonal pipe filter layer. (9) Isolation of geotextiles between roads, airports, railways and artificial rockfill and foundations. (10) internal or horizontal drainage of the dam, buried in the soil to dissipate the gap water pressure. (11) Drainage of the bottom of the impervious geomembrane or the lower part of the concrete face in the earth dam or embankment. (12) to exclude the surrounding water seepage of the tunnel, to reduce the external pressure of the lining and the surrounding water infiltration. (13) Drainage of Foundation of Artificial Filling Ground. (14) roads (including temporary roads) railways, embankments, earth dams, airports, sports and other projects to strengthen the weak foundation.

- Q:Are geotextiles suitable for use in waste containment systems?

- Yes, geotextiles are suitable for use in waste containment systems. They are commonly used as liners or covers in landfills and other waste management facilities to prevent the migration of contaminants and control leachate. Geotextiles provide filtration, separation, and reinforcement properties that enhance the overall performance and longevity of waste containment systems.

- Q:What is the latest offer for geotextile prices?

- Geotextile Product Description: Geotextile is made of polypropylene, acrylic yarn as raw material woven by the geosynthetics, widely used in water conservancy, electricity, harbors, highways, railway construction and other geotechnical engineering. Geotextiles Category: Geotextiles a wide range of ordinary geotextile refers to the permeable geotextile, also known as short wire geotextile, polyester geotextile other filament geotextile, waterproof geotextile and so on. Geotextile Price Description: There are many manufacturers of geotextiles across the country, the product offers different prices affected by the impact of raw materials and regional differences, a good product should be a penny goods. The price according to product specifications offer direct contact consultation 182 power 6686 words 2233 to find professional manufacturers to understand, product prices dynamic. Hope to help you

- Q:Non-woven fabrics, geotextiles and geotextile geotextile

- The same material that I specialize in producing

- Q:Geotextile, geomembrane to go to the laboratory test

- Yes, there is a corresponding national standard I am specializing in the production of geotextile materials

- Q:What are the quality control measures for geotextile manufacturing?

- Quality control measures for geotextile manufacturing typically include the following steps: 1. Raw material inspection: Thoroughly assessing the quality, specifications, and properties of the raw materials used in geotextile manufacturing, such as fibers and polymers. 2. Process control: Implementing strict control over various manufacturing processes, including extrusion, weaving or non-woven production, and coating, to ensure consistency, accuracy, and adherence to specifications. 3. In-line testing: Conducting regular tests and inspections during the manufacturing process to monitor key parameters such as weight, thickness, tensile strength, porosity, and permeability. 4. Sample testing: Randomly selecting samples from each batch and subjecting them to comprehensive laboratory tests to verify compliance with industry standards and project requirements. 5. Quality audits: Conducting periodic audits of the manufacturing facility to assess the overall quality management system, equipment calibration, personnel training, and adherence to standard operating procedures. 6. Final product inspection: Thoroughly examining finished geotextile rolls or panels for any defects, such as tears, holes, or inconsistencies in physical properties, before packaging and shipping. 7. Documentation and traceability: Maintaining detailed records of all quality control activities, including test results, inspection reports, and batch numbers, to ensure traceability and facilitate recalls if necessary. By implementing these quality control measures, geotextile manufacturers can consistently produce high-quality products that meet the performance requirements and specifications of various geotechnical applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-woven Geotextile Price Reinforcement and Drainage-CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords