Non-woven Geotextile PET Non-woven Fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Separation

Woven Geotextile and non woven Geotextiles provide long-term separation of the aggregate

base from the subgrade soil. By separating these two materials, the Geotextile maintains

the original thickness of the roadway aggregate. This is the most important Geotextile

function for roads, particularly where the road is being constructed on weak subgrade

soils.

Filtration and Drainage

Geotextile allows the ground water to pass into the subsurface drain without eroding the

soil and helping the ground from deterioration making the life of the roads very long.

Stabilization

Higher strength PP and polyester woven geotextiles provide strength to the roads thus

making it increment in the effective bearing capacity of low strength sub-grade soils and

increase the life of the roads.

Geotextile-Railways

saimanIn Railway tracks the use of high strength woven geotextiles increases the periods

between track maintenance. They are placed between the existing formation and the ballast

layer to prevent the sub-grade from pumping in to the ballast layer, thereby maintaining

structural integrity.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

- Q:What are the factors to consider when designing geotextile tubes for dewatering?

- When designing geotextile tubes for dewatering, several factors need to be considered. These include the type and characteristics of the sediment being dewatered, the desired dewatering efficiency, the required size and number of tubes, the hydraulic conditions, the site-specific environmental factors, and the available equipment and resources. Additionally, factors such as the strength and permeability of the geotextile material, the potential for clogging, and the long-term stability of the dewatering system should also be taken into account.

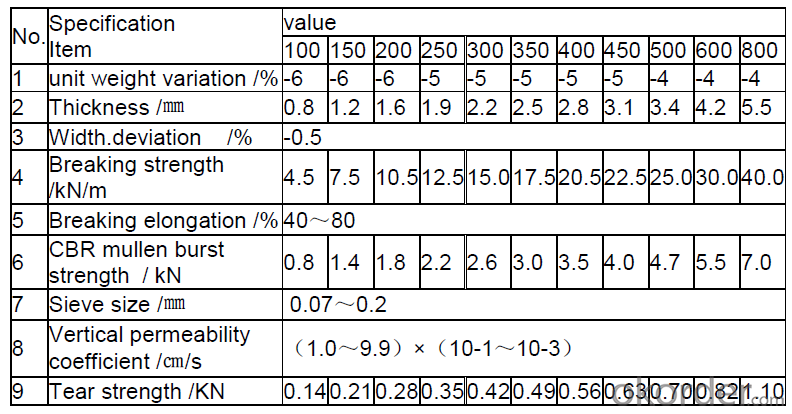

- Q:300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q:What are the different geotextile weight classes and their applications?

- Geotextile weight classes range from lightweight to heavyweight, typically categorized as classes 1 through 5. Class 1 geotextiles are lightweight and used for erosion control, filtration, and separation in landscaping and gardening projects. Class 2 and 3 geotextiles are medium-weight and commonly used for road construction, pavement reinforcement, and drainage applications. Class 4 geotextiles are heavy-duty and suitable for shoreline protection, slope stabilization, and landfill lining. Lastly, Class 5 geotextiles are the heaviest and used in geotechnical engineering for applications such as soil stabilization, embankment reinforcement, and railway construction.

- Q:Can geotextiles be used in bridge abutment reinforcement?

- Yes, geotextiles can be used in bridge abutment reinforcement. Geotextiles are commonly used in civil engineering applications to enhance the stability, strength, and durability of various structures, including bridge abutments. They can provide soil confinement, prevent erosion, and improve the overall performance of the abutment by distributing loads and reducing settlement.

- Q:How do geotextiles help with vegetation establishment?

- Geotextiles help with vegetation establishment by providing a stable and favorable environment for plant growth. They prevent erosion by holding soil in place, allowing roots to establish and anchor the vegetation. Geotextiles also retain moisture and regulate soil temperature, promoting optimal conditions for seed germination and plant growth. Additionally, they protect young plants from weed competition, herbicide leaching, and wildlife damage, ultimately enhancing the success of vegetation establishment.

- Q:How do geotextiles contribute to slope stability analysis?

- Geotextiles play a crucial role in slope stability analysis by providing reinforcement and soil stabilization. They are often used to improve the internal strength and mechanical properties of soils, preventing erosion and maintaining slope integrity. Geotextiles act as a barrier, distributing loads and reducing the potential for soil movement. Their high tensile strength helps in reinforcing slopes and retaining walls, increasing overall stability and reducing the risk of slope failure.

- Q:What are the different methods of installing geotextiles?

- There are several methods of installing geotextiles, including trench installation, direct placement, and mechanical installation. Trench installation involves excavating a trench and placing the geotextile in the trench before backfilling. Direct placement involves laying the geotextile directly on the ground surface and securing it with stakes or other means. Mechanical installation utilizes specialized equipment, such as a geotextile installation machine, to roll out and secure the geotextile in place.

- Q:Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q:How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a barrier between the soil and other materials, such as water or aggregates. They prevent soil erosion, promote drainage, and enhance soil strength, ultimately improving stability and preventing the loss of soil particles.

- Q:Please geotextile manufacturers offer,

- Please geotextile manufacturers offer,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-woven Geotextile PET Non-woven Fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords