Non-woven Fabrics Geotextile Filter Fabric for 0.25M × 10M Fabric Bag

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Introduction

Material: 70gsm non-woven fabric

Size: 0.25M*10M

Colour: all kinds of pantone colours.

Package: opp package outside of the roll, 36 rolls of big carton.

Also can put customer lable on the roll.

Made from PP(polypropylene) or PET(polyester) short fiber by nonwoven needle punched manufacturing

process. It has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

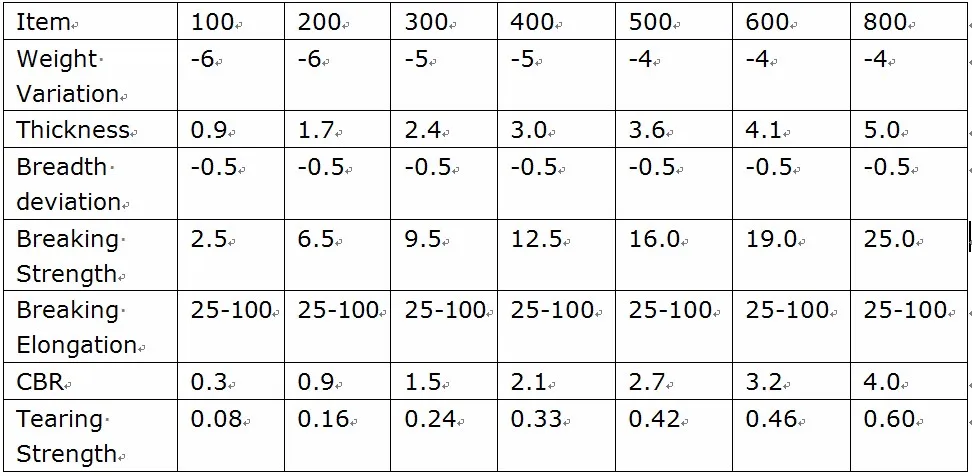

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Are geotextiles biodegradable?

- No, geotextiles are not biodegradable.

- Q:Are geotextiles suitable for use in coastal erosion control?

- Yes, geotextiles are suitable for use in coastal erosion control. They are commonly used to stabilize slopes, prevent soil erosion, and protect shorelines from wave action. Geotextiles can be installed as a barrier to filter sediment and retain soil while allowing water to pass through, effectively controlling erosion in coastal areas.

- Q:How do geotextiles affect soil compaction?

- Geotextiles can help reduce soil compaction by providing a porous layer that allows for better water infiltration and air circulation. This prevents the soil from becoming compacted and allows it to maintain its natural structure and permeability.

- Q:Geotextile seam construction how to do

- Sewing of geotextiles All sutures must be carried out continuously (for example, spotting is not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). The seam of the geotextile seam is covered by a single line of thread lock. The line used for suturing should be a resin material with a minimum tension of more than 60N and is resistant to chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation. Cloth lap according to the terrain and the use of functions can be divided into natural lap, seam or welding. Geotextile manufacturers, for your answer

- Q:Can geotextiles be used in landscaping?

- Yes, geotextiles can be used in landscaping. They are commonly used to control erosion, separate different soil layers, and provide stability to slopes or retaining walls. Additionally, geotextiles can be used as a weed barrier, allowing water to pass through while preventing weed growth in landscaped areas.

- Q:Construction scheme of geotextile water filter

- Second, the design: program one: in strict accordance with the requirements of the national standard construction, 5-year warranty 1, in the smooth level of leveling the overall construction brushing JS waterproof latex or polyurethane waterproof coating, the thickness of the national standard 1 standard; Weak parts to do additional layer to strengthen; 2, do 20 ~ 30mm thick waterproof mortar protective layer, divided into two construction, layer waterproof layer of pulp interface; require nano-silicon waterproofing agent and expansion agent compound use. 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice ibid, the wall to do high 1m. Option 2: with reference to national standard requirements simple practice, the warranty period of 1 year 1, the overall construction of coated asbestos asphalt waterproof coating or waterproof cold primer, the thickness of the standard by the national standard 2; special weak parts to do additional layer to strengthen; Outside the protection, requiring the use of sticky or sticky sticky construction; 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice reference program one, the wall to do high 1m.

- Q:What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include the material composition, UV exposure, chemical resistance, physical properties, installation and maintenance practices, and environmental conditions such as temperature and moisture levels.

- Q:How do geotextiles improve the performance of pavement structures?

- Geotextiles improve the performance of pavement structures by enhancing their strength, stability, and durability. They act as a separator between the subgrade and the pavement layers, preventing mixing and intermixing of these materials. Geotextiles also help in distributing the load from traffic more uniformly, reducing stress and potential damage to the pavement. They can also act as a filter, preventing the migration of fine particles from the subgrade into the pavement layers, which can further destabilize the structure. Overall, geotextiles enhance the longevity and functionality of pavement structures.

- Q:What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as the material type, weight, permeability, and strength. The geotextiles should be made of durable and non-biodegradable materials such as polypropylene or polyester. The weight of the geotextiles is generally specified in terms of grams per square meter (gsm), with heavier weights often preferred for better performance. Permeability is an important factor, and geotextiles with high permeability allow for efficient water flow while preventing soil erosion. Additionally, the geotextiles should possess adequate strength to withstand installation stresses and ongoing loadings. Overall, the specifications ensure that the geotextiles effectively separate, filter, and reinforce the soil in drainage projects.

- Q:The amount of geotextile drainage of the drainage pipe, as well as the amount of gravel block ye count

- Calculate the surface area of the water pipe, and then add a 10% of the amount, is the amount of geotextile, Huazhi geotextile material manufacturers to answer

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-woven Fabrics Geotextile Filter Fabric for 0.25M × 10M Fabric Bag

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords