non woven fabric manufacturer wet wipes material spunlace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

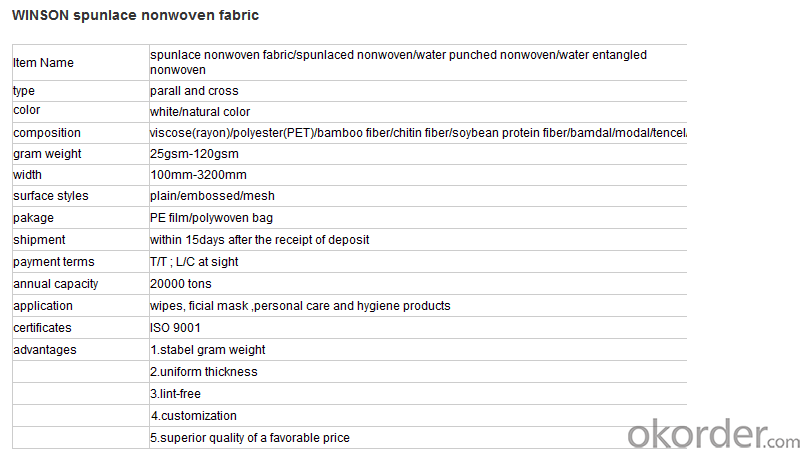

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q:The development of wool in Australia is not developed.

- The main trading partners are Japan, the United States, mainland China, South Korea, Britain, New Zealand, Singapore, China Taiwan Province, Germany and Malaysia.

- Q:What are the common textile auxiliaries?

- To give textiles a special function and effect, improve product performance and added value

- Q:Textile enterprises to operate the project: processing and production are different?

- While the latter is the production of independent arrangements, that is, the production of products is based on the market or orders or contracts and other arrangements.

- Q:What are the classification of the textile?

- There are chemical processes exist in each process, but there are most chemical processing to the number of chemical fiber industry and dyeing and finishing industry.

- Q:Are hats a class of textile and apparel products?

- Hats are popular for textile products, processing or general trade.

- Q:The meaning of the following terms in the textile industry: fabric, processing number, genuine number.

- Jeans shrinkage is generally 15% to 40%. Look at the thickness of the fabric, and is not elastic, there are scrub, yeast, wash, rinse, rancid wash, and so on, different washing water has different washing steps, procedures

- Q:How to detect formaldehyde content of textiles?

- In addition, the textile in the crease-resistant finishing often used in the anti-crease finishing agent monohydroxymethyl dihydroxy vinyl urea, referred to as 2D resin, mainly in order to improve the cellulose fiber and blended fabric wrinkle resistance, shrinkage performance.

- Q:Do you need to do environmental protection for dry textile processing?

- Family business is to all the property owned by the family, personal business is funded by the individual property.

- Q:Textile finishing TPU, TPEF film. What's the difference?

- High mechanical strength. TPU products carrying capacity, impact resistance and shock absorption performance. TPU

- Q:How can paint points be removed during textile processing?

- The cross-linking agent, the adhesive is a polymer resin, they are in the air at high temperature polymerization, the coating macromolecular particle network within them

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

non woven fabric manufacturer wet wipes material spunlace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords