Non-explosive Demolition Agent

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non-explosive Demolition Agent

Description

NDA is a soundless and safe demolition agent which is quite different from ordinary demolition agents such as explosives and dangerous materials. It does not cause any fly rock, noise, ground vibration, gas, dust or any other environmental pollution when used properly.

As requirements for cracking the stone and demolishing rock and reinforced concrete in construction increase in tight quarters, the use of explosives and explosive agents is becoming more restricted as far as safety and environmental pollution problems are concerned.NDA is the best solution.

Usages

• Granite, marble, sandstone, limestone, quartzite quarrying.

• Rocks pre-splitting, fracture, cutting, demolishing and removal.

• Controlled demolition or cutting concrete.

• Fracture and demolition of the concrete buildings and structures.

• Excavation of trenches and foundations.

• Underground excavation and removing boulders.

• Marine excavation including underwater operations

Advantages

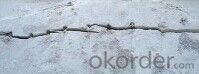

• Amazing Expansive Capability

Amazing expanding capabilities breaks reinforced concrete, rock, marble, granite, limestone or any material you are working with. Depending on the material you are working on.

• Easy to use

No formal training required before use. Just mix with water and then fill into holes. Once mixed with clean water, CRACK.AG can be poured into holes pre-drilled in the material you are working with It can be poured into the same holes that dangerous explosives are usually placed in.

• Non-Explosive Environmentally Friendly

Much safer than explosives, with NO Noise, NO Vibration, NO Flying Rocks and NO Toxic Gases.

• Works Efficiently and Cost Effectively

No Special License, training or equipment needed.

Types

Depending on temperature, there are three types.

SCA Types | Temperature (Celsius) |

MNC-SCA1 | 25 - 40 degree C |

MNC-SCA2 | 10 - 30 degree C |

MNC-SCA3 | -5 - 15 degree C |

Package & Storage

40 kg paper-plastic bag package.

1. Although NDA is packed in anti-moisture paper bags, long storage may cause deterioration of its working ingredients. Therefore, store in a dry place and use it as soon as possible.

2. When storing, do not place the bags of NDA directly on floor, put them on a pallet and keep in a dry warehouse etc. NDA stored in this manner, can be effectively used for about 1 year.

3. MDA should be unpacked before use.

4. When storing the portion of NDA remaining after use, push the air out of the bag, then seal with gum tape and use as soon as possible. However, as it may get exposed to moisture there is a risk of NDA losing its effectiveness once the bag has been opened.

5. If you receive broken bags of NDA, they may not work due to chance of moisture absorption.

- Q:What is the difference between a waterproofing agent and a waterproof coating?

- Waterproof coating is directly used for the construction of waterproof layer of waterproof slurry, such as the dragon one-component polyurethane waterproof coating directly open cans to form a waterproof layer; waterproof agent is the main field of tattoo fool algae add each other to the concrete, Cement mortar and other materials which increase its waterproof performance of a waterproof additive.

- Q:10 tons of dry powder mortar production line and supporting the need to invest how much money

- plant another operator, the other raw materials, there are artificial, dignitaries need 2-3 people simple analysis: 2 cubic biaxial gravity mixer mixed 1

- Q:Recently to do the concrete (texture) model, probably a flower pot size, to find the next material, only to find mortar, mortar, yellow sand and the like, cement, then it seems to sell a few bags of white water Danti orange Li Li mat Dead mud, or white portland cement. What I want to do is the kind of concrete that is gray. Do not know what materials I want to stir or mortar mixing directly to the abrasive on the like? If you want to use the mortar, then, is to buy rigid or flexible? More

- Directly on the mold on the line, buy a good good

- Q:Waterproof engineering should be arranged at what time to do the best?

- If it is interior decoration, in the indoor civil engineering and buried after the completion of the dark tube, began to carry out the best.

- Q:What waterproof material can be combined with cement mortar to play a waterproof effect?

- Recommendation: If the price is not the first element you consider, this approach is very reasonable In favor of your practice If you have to consider the price is only the first step of the stalks Li Li pad when the Qujiangjiang with a like, so as not to cause unnecessary waste Note: good waterproof material, but also need careful construction, "construction process" is the key to the late conservation, protection to do bedding, in order to effectively do a good job waterproofing Materials, the best choice cement-based flexible waterproof coating mortar waterproof non-toxic environmentally friendly waterproof mortar can be

- Q:Are those materials in the construction project required to be tested?

- Are those materials in the construction project required to be tested?

- Q:What is good for the waterproofing layer of the outer wall of the basement?

- polystyrene foam board (ordinary or extruded board), construction attention to the backfill to be tamped, strictly prohibited the impact of rock damage to the foam board cement mortar protective layer, waterproof material is difficult to mortar surface, the lower the height can be used other such as wood, polyethylene foam membrane can also be used There are polystyrene board and masonry protection wall practice, masonry protection wall and waterproof layer between the use of Gongshi grams of grams of long-term Hinffe squeeze-type insulation polystyrene board, play anti-condensation and waterproof waterproof double effect

- Q:Building floor moisture, please tell me about the building floor moisture, mainly want to understand the capillary phenomenon of building materials and prevention.

- Moisture layer practice can check the wall of the block wall details, such as 88J2 & amp; lt; a & amp; gt; "wall - brick

- Q:I would like to check, I would like to ask C. C20 with more than how to check, there are mortar M5 cement, mixed mortar how to check, the need for any material.

- Mortar is mainly sent to the cement and sand; and then to the test unit to fill the next order, indicating the design strength and consistency there are structural parts; if you have added mortar or admixture and the like, to refer to the added material certificate above The best proportion to add, the general inspection when the inspection unit will require a copy of a certificate

- Q:Insulation putty can be used alone as an external wall insulation material? Whether the external wall insulation putty can replace the external wall mortar

- Under normal circumstances need to use with the insulation materials

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-explosive Demolition Agent

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products