Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

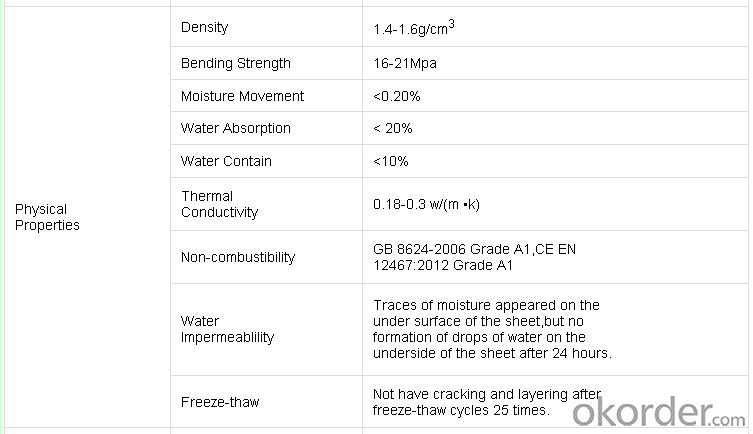

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

Images:

- Q:This is behind my vinyl siding and above my drop tile ceiling.

- It would most likely be asbestos because nobody in there right mind would cover Hardi with vinyl.

- Q:Home improvement wall is made of light steel keel + gypsum board, light steel keel + cement pressure plate is good or red brick light weight brick good?

- With light steel keel + sound-absorbing cotton, gypsum board partition This is the best light steel keel can open the secret of some kick is kicked into the exaggerated words do not believe

- Q:We recently hired a contractor to remodel the entire bathroom due to water damage. We are getting close to tiling. There is a tub going in then the walls will be tiled for the shower.The contractor put green board in the entire bathroom first. Then he put water barrier paper over the green board in the areas that will be tiled. Then put hardy backer cement board over that. Is this a good way to do it? There is no cement board below a certain height because the tub will be there. I wasn't sure if this is a good way to do it?

- It's fine. I wouldn't have put the green board up where the cement board was going up, to save time an money. The green board is unnecessary there. But, it won't cause any problems.

- Q:What is the difference between a cement pressure plate and a cement board?

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Widely used in civil and industrial buildings. Can be used for building floor, interior wall panels, exterior panels, ceiling panels, curtain wall panels, composite wall panels, insulation materials, roofing and other parts.

- Q:Cement board spray really stone paint

- With insulation board, adhesive mortar wiping mortar, primer, really stone paint, varnish can be strong, solid, three-dimensional.

- Q:We have drywall in our kitchen that was painted with a smooth semi-gloss paint a good 8 yrs ago. We'd like to install 3x6 tumbled marble as a backsplash over the drywall. It's about 1/4 thick so probably slightly heavier than say, the tiny square glass tiles that come on a 12x12 netting. One person at the Home Depot said we could just sand and scrape up the drywall and then apply the thinset and install the marble. Another said we might want to use a cement backing. We aren't really DIYers and would so we don't want to create extra work with the cement backing if it isn't needed. That said, we don't want the drywall to start peeling and the marble tiles to start falling off after a short amount of time. Please advise. Thank you!

- I would recommend screwing wonder board over the drywall before putting the tile up. This will give you a long lasting application. It will not up your cost a whole lot and you will be much happier in the long run.

- Q:Want to know the cement fiber board recipe and check your product for compliance

- Add a new type of building material that is made of plant fiber, pulping, picking, pressing, and curing. Nowadays the most popular micro-spectrum analysis method through a variety of micro-spectrum analysis to accurately obtain the exact proportion of each component, access to high-quality formula.

- Q:Anyone that can supply UAE - Middle East, preferrably from the UK, Europe, Australia and New Zealand.

- We okorder . Thanks, Rajesh Contractor

- Q:A grade fireproof material cement board

- High fire resistance NK-YB01 composite foam cement board is an inorganic material, is a Class A fireproof material, which has a good fire resistance, refractoriness of 1000 ℃ or more, fully meet the external wall insulation requirements.

- Q:What is the prc in the building?

- PRC (Pore Reduced Cement) is a high-performance cement material, it is in the process, performance, use, etc. have many unique advantages

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords