Newest design!!automatic double-needle galvanized mesh scourer machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Mesh scourer making machines

High output and quality

Professional supplier

Best price and service

Easy to operate

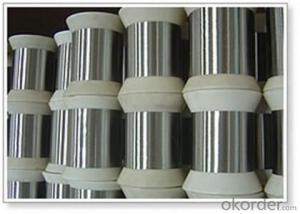

.product photo

- Q:How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- First wear latex gloves, detachable parts are removed inside the oven, such as baking, chassis, and then with a neutral detergent washing, paying special attention to oil dirties is very heavy, can use special cleaning fluid, such as the kitchen cleaner to do the key parts of decontamination. Then put an old newspaper in the door of an embedded oven and brush the broken pieces of the oven out of the oven with a small brush. Outside of the inside of the oven to heat pipe and heat pipe shield must use dry cloth to wipe gently, can't use a wet cloth, so as not to affect the heating pipe insulation, leakage phenomenon of short circuit. Except for the removable part of the oven, it is not possible to scrub clean and water with water or a wet cloth. If found the heating tube and fence are dirty, with dry cloth to wipe clean, also can not change with the rough surface such as steel wire ball, clean ball cleaning tools to wipe. If you have wire or hard particles falling into the heating tube, light barbecue an unpleasant feeling of anxious burnt flavour, or cause the entire circuit short circuit, can try to use clean force strong nylon cloth is wiped a few times more. After cleaning the heating tube, you can begin to clean the outer shell of the oven and the inside bladder. The cloth in the diluent of neutral detergent slightly wet, wipe with wet wipe the body shell, dip again after cleaning, diluent, and wring dry, into the oven inside pumice, final reoccupy clear water rinse wipe dry after dry, wipe it twice.

- Q:What are the types of cleaning equipment

- The question you ask is unscientific, and there is no way to answer it at all At least a small class

- Q:The heavy oil on the machine should use what cleaning agent to clean up?

- The downstairs brother was right. I'm the one who often USES this oil cleaner, Because it's local, it's clear that it works well. I recommend you to consult..

- Q:What are the methods of general cleaning of mechanical equipment?

- It is commonly used for dry cleaning and washing 1, dry cleaning: it is with a bit like a sponge absorbing water materials, such as spray (drop) some detergent or anything on the brush, complete with relatively wet objects in to wipe again, finally just now with the dry items all dry clean place (general comparison precision of the equipment) 2, rinse directly with water, direct and clear, and then dry (directly dry, the equipment is large). This kind of equipment is not afraid of water Most of it comes in the first way

- Q:Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- Last year took part in the issue of dedicated to verify training on cleaning validation Wang Yanzhong teacher to explain this one is so blue font: if you don't clean immediately after the equipment use, such as when a couple of days to clean again, need to confirm according to have validated cleaning method can clean the equipment when cleaning equipment, there may be some material put a few days after has been hard on the equipment surface, not as easy as immediately when cleaning clean. So the time that the device is used up to cleaning is going to be validated.

- Q:Characteristics of cleaning equipment of cleaning equipment

- High pressure cleaner using high pressure water jet cleaning technology, which is in the 1960 s the rise of a technology, widely used in the removal of incrustation scale proliferation, oil and other hydrocarbons residue coking, also can remove all kinds of coating stab stick coagulation soil lipid layer of gypsum, pigment, rubber, plastic, etc

- Q:What are the benefits of sanitation

- The protection equipment and make it is not too bad

- Q:What is the pool cleaning equipment

- Disinfection system (water treatment of swimming pool is very important, the water quality is not up to the standard to affect the opening) : Metering pump Drug delivery; Ozone generator. Lighting system (underwater lamp beautification swimming pool) : Pool wall lamp; Waterproof cable. Fully automatic thermostat (the temperature of the water in the swimming pool) : Fully automatic heating furnace; Water and water heat exchanger (commonly known as plate change); Temperature controller; Electric valve. Cleaning equipment (pool brush, leaf net, telescopic rod, suction head, wire brush). 5, the pool bank facility (escalator, departure stage). Water quality monitoring equipment (water quality monitor, test water box, water temperature meter). Water treatment pipe fittings.

- Q:What are the sanitation facilities?

- Sanitation equipment including road cleaning equipment, trash pickup device, the landfill treatment equipment, now the fog haze weather serious mainstream sanitation develop haze reduction equipment manufacturer. And so on.

- Q:Clean the cleaning parameters of the equipment

- The main still should see you clean thing, clean the rough, no strict requirements to surface with low frequency is ok, but for some mesh class cleaning high frequency, it is best to this can reduce the workpiece of ultrasonic cavitation effect. Secondly depends on the choice of cleaning medium, weak alkaline medium SUS304 steel can, weak acid or not enough, easy to form in acoustic surface acidification, steel easy ageing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Newest design!!automatic double-needle galvanized mesh scourer machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Sets set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products