New Male Valve PPR Pipe Fittings For Industrial Application with High quality in 2017

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of Products

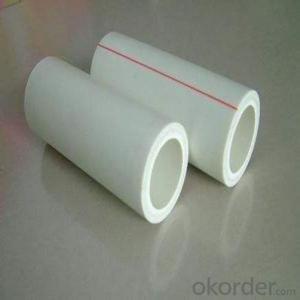

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Product Show

Product Advantages

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

Feature

1) The professional factory of fittings.

2) The important manufacture of fittings in china.

3) High quality and better price

4) Convenient One touch fittings provide instant tubing connections:

5) Elliptical release ring help to connect the tube easily by manual, no special tools required.

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

Q5: What you offer?

A5: Any kinds of goods you need, just send us the request, we will reply you back with the details very soon.

- Q:Can plastic pipe fittings be used in laboratory systems?

- Yes, plastic pipe fittings can be used in laboratory systems. They are commonly used due to their durability, chemical resistance, and affordability. However, it is important to ensure that the specific plastic material used is compatible with the chemicals and substances being handled in the laboratory to avoid any potential reactions or contamination.

- Q:Can plastic pipe fittings be used in stormwater management systems?

- Yes, plastic pipe fittings can be used in stormwater management systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. They are available in various sizes and configurations to meet the specific requirements of stormwater management projects.

- Q:PPR pipe fittings, copper pieces, that are embedded parts and plastic parts are not good, appear pressure leakage situation

- The water supply pipe is connected with the metal pipe polypropylene, polypropylene pipe should be used with metal fittings as a transition, the pipe and the plastic pipe by hot melt connection, connected with the metal fittings or sanitary hardware fittings with wire.

- Q:Can plastic pipe fittings be used for stormwater drainage systems?

- Yes, plastic pipe fittings can be used for stormwater drainage systems. Plastic pipe fittings, such as those made from PVC or HDPE, are commonly used due to their durability, corrosion resistance, and affordability. They are also easily available and can be installed quickly, making them suitable for stormwater drainage systems.

- Q:How do you connect plastic pipe fittings to copper pipes?

- To connect plastic pipe fittings to copper pipes, you can use a transition fitting. This fitting typically has a threaded end that screws onto the plastic fitting, while the other end is soldered or brazed onto the copper pipe. It creates a secure and leak-proof connection between the two different materials.

- Q:Are plastic pipe fittings suitable for chemical scrubbing towers?

- No, plastic pipe fittings are not suitable for chemical scrubbing towers.

- Q:Are plastic pipe fittings resistant to sunlight exposure?

- Yes, plastic pipe fittings are generally resistant to sunlight exposure.

- Q:What are the common connecting methods for plastic PP pipes?

- The common ways of connecting plastic pipes are adhesive connection, rubber ring connection, welding connection, and mechanical (clamp type pipe fitting) connection. For polypropylene (PP) pipes, there are three common ways of connection, namely, hot wire welding, butt welding and loop flange connection.

- Q:Can plastic pipe fittings be used for rainwater diversion systems?

- Yes, plastic pipe fittings can be used for rainwater diversion systems. Plastic fittings are commonly used in such systems due to their durability, affordability, and resistance to corrosion. They are also lightweight and easy to install, making them a popular choice for rainwater diversion projects.

- Q:How do plastic pipe fittings compare to brass fittings?

- Plastic pipe fittings are generally cheaper and easier to install compared to brass fittings. However, brass fittings are more durable and have a longer lifespan. They are also better suited for high-pressure applications and provide a more secure connection. Ultimately, the choice between plastic and brass fittings depends on the specific requirements of the plumbing system and the budget of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New Male Valve PPR Pipe Fittings For Industrial Application with High quality in 2017

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords