New Dop Plasticizer Alternative DEDB Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product performance:

Polyol Benzoate (DEDB) is colorless or pale yellow transparent oily liquid, water-insoluble, soluble in aromatic hydrocarbons, ketones and ethers, and has good compatibility withpolyvinyl chloride, ethylene - vinyl acetate copolymer, poly vinyl acetate, polymethylmethacrylate, polyvinylbutyral, nitrocellulose, and ethyl cellulose, etc.

Product application:

Polyol Benzoate(DEDB) is an environmentally friendly plasticizer with the characteristics of strong solubility, good compatibility, low volatility,resistant to oil, water, light, pollution etc. It is suitable for processing PVC flooring material, plastisol, artificial leather, cable material, soft and hard pipe, shoes material, rubber strips, synthetic rubber, and paint, printing ink, etc. It has a better plasticized effect if it is used together withDOP or DBP, and has greatly achieved the purpose of reducing cost .

Product quality index

Item | First grade | Second grade |

Chroma(APHA) ≤ | 50 | 60 |

Ester % ≥ | 99.5 | 90.0 |

Density(20°C)g/ | 1.120-1.126 | 1.172-1.78 |

Acidity(as benzene dicarbonic acid) % ≤ | 0.01 | 0.02 |

Flash Point °C ≥ | 195 | 192 |

Loss on heat(125°C,2 hours)% ≤ | 0.3 | 0.5 |

Chroma after heat treatment | 80 | 100 |

Specifications

1. Direct producer with 15 years experience

2. ISO9001:2000

3. High quality, lower price and best service

4. New plasticizer

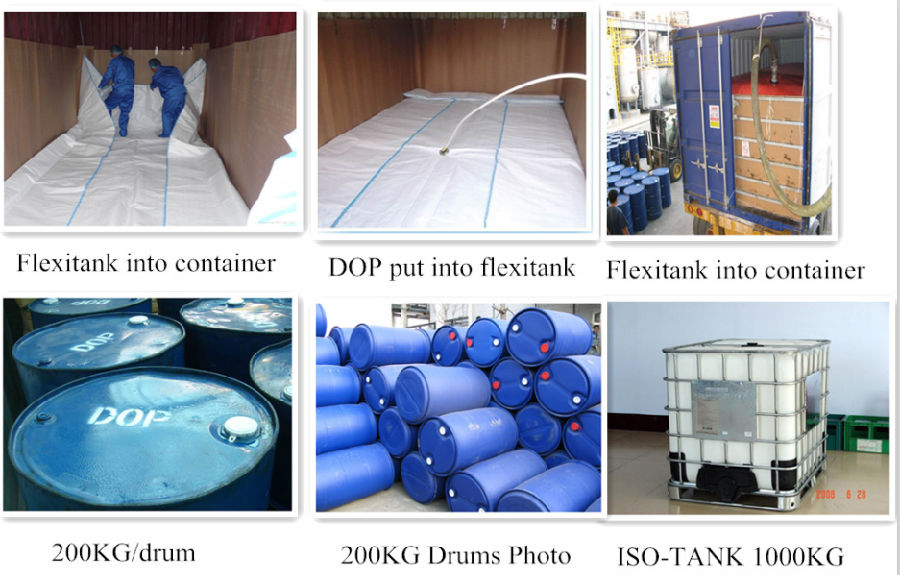

Packaging: IBM, net weight: 1000 kg.

Our Factory:

Our Factory:

- Q:Why the catalyst after the chemical reaction of its quality and chemical properties unchanged

- In fact, the catalyst reaction also enters, which changes the rate of positive and negative reactions ... enhances the reactive molecules of the reactants, thereby changing the reaction rate ...

- Q:A biological catalyst or a chemical reaction facilitator is know as a/an?

- organic and organic catalyst is called ENZYME. A chemical reaction facilitator is called Catalyst A organic and organic molecule that aids enzimes paintings is called Cofactor despite if it extremely is metallic or coenzyme if its organic and organic in foundation.

- Q:And hydrogen peroxide

- No

- Q:What is the quality of the catalyst in the chemical reaction, for example, 34.3 g before the hydrogen peroxide reaction, 32.7 g after the reaction, and how much is the catalyst mass?

- You can not calculate this question, the quality of the catalyst before and after the same reaction, how much reaction before the reaction on how much

- Q:Co and No form a chemical equation for Co2 and No2 under the action of a catalyst

- 2CO + 2NO == N2 + 2CO2

- Q:i know that the catalyst is not react in an reaction,,,so that i don't why could it speed up the reaction?? Further, how does the scientist determine the catalyst for certain reaction??please give me more example....i really want to know it! i do not have any idea about this...so hope your answer will help me....thanks!

- you can say catalyst react with the reagent and it gives intermediate product, this product can easier react with another reagent (the activation energy is lower). And in the end the catalyst is reconstructed. Scientists determine the catalyst in experiments...

- Q:Can a catalyst decrease the rate of a chemical reaction? Please give an example if yes.

- no, by defintion the catalyst speeds up the reaction.

- Q:Chemistry teaching and learning a bit difficult, thank you

- 2NO + 2CO = 2CO2 + N2

- Q:Chemical Glossary: Catalyst

- The catalyst is a substance that can change the rate of the reaction without changing the standard of the reaction Gibbs free, according to the definition of the International Pure and Applied Chemistry (IUPAC) in 1981, Enthalpy change. This effect is called catalysis. The reaction involving the catalyst is a catalytic reaction.

- Q:What is the reaction in chemistry?

- Industrial production of ammonia, ethanol, industrial synthesis of ammonia, ethanol catalytic oxidation, acetaldehyde oxidation into acetic acid, ethyl acetate preparation, the transformation of automobile exhaust, benzene substitution reaction and addition reaction, some other addition reaction of hydrocarbons, Ethanol dehydration to produce ethylene and so on

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New Dop Plasticizer Alternative DEDB Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords