New 2014 WPC hollow decking ( SGS,FSC ,CE ,EU standard etc.)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood-Plastic Composite (WPC) floor accessory is manufactured from a combination of plastic, natural fiber and some additives using special equipments. It mixes natural fiber and plastic perfectly to keep the natural impression of wood but with rich colors of plastic. It has gradually replaced wood and plastic, getting widely used in more and more fields.

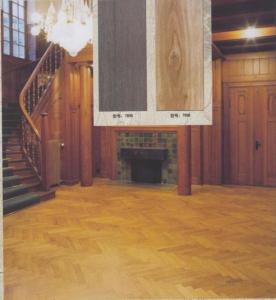

For our wpc decking floor, there are many kinds of types, such as TW-K01(150 x 35 mm)TS-01(150 x 25mm), TH-07(140 x 30 mm), TS-A01(90 x 20mm),TH-16(133 x 24 mm, solid design) etc..

1. Material: 50% natural wood flour; 35%~40%HDPE, 10%~15% additives

2. Color: cedar, grey ,red pine, coffee, brown, nature wood etc.

3. Usage: outdoor, garden, summer house, villa, pool surrounds, exterior floor, seaside walk board etc.

4. Normal length: 5.4 meters/pc, can also be cut according to the requirement of customer.

5. Surface treating methods: Brushing, groove, sanding, embossing etc.

6. CE Approved

7. Advantages:

Keep the excellent character of plastic | Have the properties of wood | Produce fire-new WPC |

weatherproof | easy to cut, fix and glue | Can be recycled with 100% |

no crack, split, warp, or splinter | easy to tenon , drill and nail | No sting of wood |

High dimensional stability | Natural feeling0 | Requires less routine maintenance |

Resistance to insects | Resistance to UV | Is environmentally friendly |

easy to manufacture manifold profiles | innocuous | Multicolor, and needn't to painting |

- Q:Will you, home improvement shop floor is not the last time, shop floor, what else to do it? Thank you!

- No, the last process is to install the skirting board, after the shop also waxing

- Q:We are considering slate floors for the bathroom remodel we are doing. Are they difficult to maintain and are they a good choice for the bathroom?

- have slate floors in my bathroom-love them. they're pretty easy to keep clean. the guys that did the work are unbelievably messy, so after they were done with all of the other stuff, it took me forever to get the grout that they dropped all over the place up! but they are really pretty. another nice alternative is mexican terra cotta tile. you can find them wholesale at lots of places, but you have to seal them yourself. the beauty of tc tile is that you can tweak th ecolor by adding wood stain. i love the slate tiles, though.

- Q:im looking into getting my dad a new jack for fathers day. What is the difference between a hydraulic jack and a floor jack? What would you recommend and why? Which would be better?

- A floor jack is a type of hydraulic jack, if you are referring to a bottle jack vs a florr jack than floor jack all the way. A floor jack is generally the best choice for people who work in their garages, but do not forget a pair of jack stands if he is putting any part of himself under the vehicle. A floor jack has a bigger lifting surface than some other types of jacks and generally has a higher lifting height as well, which has obvious advantages.

- Q:Floor tile commonly used size and floor tile type

- Size 800 * 800, 600 * 600/300 * 450, etc., type glazed, polished, antique, vitrified, etc.

- Q:I need to replace the floor in my shed. I'm thinking of raising the walls and replacing the floor with the walls raised.Any ideas on how to do this?

- 1. Empty the shed. 2. Disconnect the walls from the floor. 3. Use a floor jack and a 4X4 to jack up one side of the shed. You will need someone to hold the 4X4 vertically with one end on the jack so that the other end can be jacked up to reach a structural part of the roof or a rafter. Jack the side up about 3 inches. 4. Place a 2X6 board under the raised side with the flat sides of the board parallel to the ground and placed so that the board extends about 3 feet beyond the shed on both sides and so that the wall will sit on the 2X6 when you finish step 5. 5. Lift the 2X6 up until it touches the underside of the shed edge. Prop the board up on other boards so that there will be about 2 inches available under the board 6. Repeat steps 3, 4, 5 on the other side of the shed. 7. Continue lifting the same two sides 3 inches at a time until you have the shed sitting on 2X6 boards and the boards on cinder blocks about 8 inches above the ground. Don't lift one side all at once because some sheds are flimsy and would collapse unless you alternate lifting the two opposite walls. 8. Replace the floor. 9. Use the floor jack and the 4X4 to take one side of the shed at a time off the boards and remove the 2X6 boards and cinder blocks. Do the lowering a couple of inches at a time alternating between the two walls that are on the boards. 10. Connect the walls to the floor. 11. Take lots of pictures before, during and after. 12. Brag until everyone is tired of hearing about it. Mayan

- Q:We have Brazilian Cherry hardwood floors. Nothing I do seems to remove the streaking. I have wet mopped, steam mopped, used floor products with a dry mop, but always I can see streaks in the floors. Any suggestions on how to get them shiny and streak free?

- Spray thick amounts of bleach all over the floor. Then if you want you could put some car oil and mop it around too.

- Q:The flat above mine has squeaky floors and it is, at times, unbearable. The problem is that the floors are 'floating floors' and they haven't been laid properly. My flats are 5 years old and I have a 10 year warranty, although the builder says the floors only have a 2 year warranty. Can anyone shine light on this situation??

- A lot of times electricians and pipe guys drill a lot of holes in the main supports when the place is being built. If they drilled through main glue lamb support beams then they should have to fix it. Maybe it rained a lot when they were building the place and it flooded and the wood is warped and rotten in some places. Try a little investigation, however there are a lot of carpenters who would LOVE to fix your floors right now.

- Q:I have an acid washed concrete floor in my business. I am having a problem with the floor being hazy/dirty after washing. The floor is waxed. When i clean the floor I use 2 buckets of water ... One with neutral floor cleaner and one clean water rinse bucket. After the floor dries it has a haze over it ... if i rub my fingers on the floor the haze goes away but my fingertips become black from the residue ... what can i do to get my floor back to clean ... i get so many compliments on the dirty floor and i cant imagine what they will say once it is really clean ... Any Help Would Be Appreciated ....Thank You

- one possibillity is you're using to much neutral floor cleaner, and not rinsing well enough. if as you say the floor is waxed thats about the only likely cause.

- Q:How to choose to strengthen the floor?

- Take sandpaper to polish, if the floor after grinding traces on the bad. General good quality of the floor will not appear too obvious traces!

- Q:im trying to solve 16=floor((100*floor(.15*X))/86), but i dont exactly know how

- The floor function maps a range of numbers into a single function. So there are infinitely many solutions. You could solve it as an inequality. 16=floor((100*floor(.15*X))/86) means 16 <= 100*floor(.15*X))/86 < 17 Rearrange those inequalities to isolate floor(.15*X). Then on each side you'll once again have a range of values for .15*X. Edit: 16*0.86 <= floor(.15*X) < 17*0.86 13.76 <= floor(.15*X) < 14.62 But because floor is an integer, that means that floor(15*X) has to be 14. It's possible I might have gotten a range of integers at this point. floor(.15*X) = 14 14 <= .15*X < 15

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New 2014 WPC hollow decking ( SGS,FSC ,CE ,EU standard etc.)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products