Needle Punched Polyester/Polypropylene Manufacturer Nonwoven Fabric Non Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Needle Punched Polyester/Polypropylene Manufacturer Nonwoven Fabric Non Woven Geotextile

Desciriptions:

Polyester Nonwoven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications.Made from PP (polypropylene) or PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function. It separates, stabilizes, and reinforces soils and allows for filtration Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

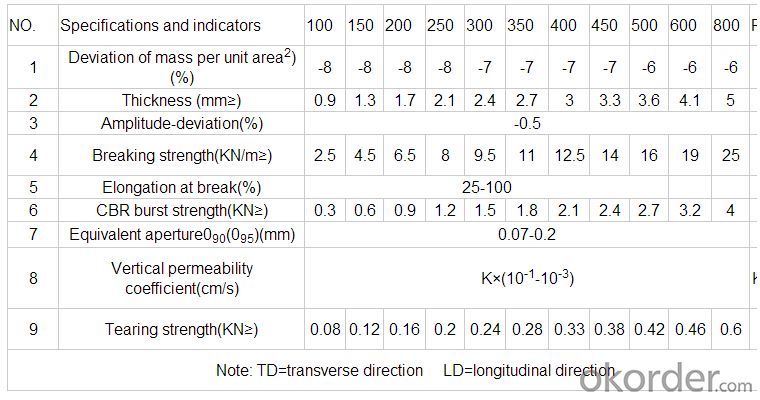

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function

Details of our products:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What can the geotext crushed material be used?

- Can continue to be used to do geotextile, but because the geotextile after the strength of the fiber is affected, can only be crushed after the geotextile for the production of low grade geotextile, for example, the national standard geotextile crushed material can generally be used Non-standard geotextile production, but in strict accordance with the proportion of added, should not add too much crushed material.

- Q:Geotextile CBR tear strength rate is how much

- Geotextile CBR bursting strength is generally in accordance with the national standard GB / T-2017 "geosynthetics static top breaking test (CBR method)" according to the national standard GB / T-2017 standard requirements of geotextile CBR strong pre-tension 20N. According to the national standard GB / T-2017 standard requirements of geotextile CBR strong rate of (50 ± 5) mm / min.

- Q:How are geotextiles used in landfills?

- Geotextiles are used in landfills as a protective barrier or liner, preventing the contamination of soil and groundwater by acting as a barrier between the waste and the underlying natural environment. They help to control the flow of liquids, filter out pollutants, and provide stability to the landfill structure, ultimately enhancing environmental protection and the longevity of the landfill.

- Q:U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q:How do geotextiles contribute to sustainable drainage systems?

- Geotextiles contribute to sustainable drainage systems by providing effective filtration and separation of soil layers, preventing clogging and improving water infiltration. They also help in reducing erosion and promoting vegetation growth, thus enhancing the overall sustainability and longevity of drainage systems.

- Q:Geotextile how to do on-site measurement

- Geotextile is calculated by the square, you only need to measure a long, wide, calculate the area will be able to know how much geotextile, and hope to help you!

- Q:How do geotextiles improve the performance of pavement structures?

- Geotextiles improve the performance of pavement structures by providing separation, filtration, and reinforcement. They prevent the mixing of different soil layers, allowing each layer to function independently and efficiently. Geotextiles also act as a filter, preventing the clogging of underlying drainage systems by allowing water to pass through while retaining the soil particles. Furthermore, they reinforce the pavement, distributing the load more evenly and reducing the potential for rutting and cracking. Overall, geotextiles enhance the durability, stability, and longevity of pavement structures.

- Q:Where to sell black geotextile prices

- Those who produce geotextile manufacturers are selling black geotextile. Black geotextile according to the use of a lot of specifications, the price difference is very large. The weight per square meter between about 50-1000g grams, the weight of different unit price is different, the inquiry directly asked how much money per ton. According to the use of distinction between the current market price per ton price between 5,000 yuan - yuan. For the conservation, isolation, insulation of the geotextile the cheapest. In the 5000 yuan / ton between. For the filter, soft base treatment, slope protection, reinforced decoration, and other purposes of the black geotextile most expensive in - yuan / ton. The same black color, but different uses, production processes and production costs are not the same.

- Q:What is the difference in role of earth anchors and geotextiles in the construction of retaining wall?

- Geotextiles prevent the infiltration of the natural, insitu soil into sand or structural gravel that you may place as a foundation to the retaining wall. You can think of it as a membrane that keeps the two types of material of different densities, from gradually mixing together. A free standing retaining wall will likely not be successful as the pressure of the retained soil behind the wall will build up due to settlement, and eventually cause the wall to topple. Earth anchors that tie into the wall and extend into the backfill material (retained earth) serves to support the wall and keep it from failing.

- Q:Are geotextiles commonly used in agriculture?

- Yes, geotextiles are commonly used in agriculture. They are used for various purposes such as erosion control, soil stabilization, weed suppression, and moisture retention. Geotextiles help improve crop yield, reduce water usage, and prevent soil erosion, making them an essential component in modern agricultural practices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Needle Punched Polyester/Polypropylene Manufacturer Nonwoven Fabric Non Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords