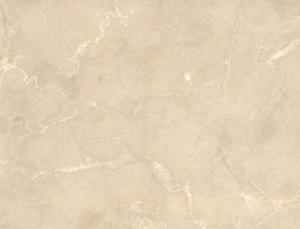

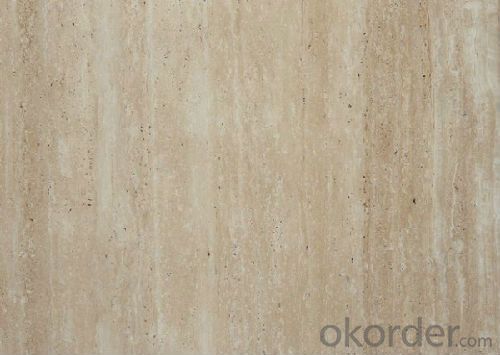

Natural Marble with Pattern in Different Size

- Loading Port:

- Fuzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1. Description

| 1 | Material | Marble |

| 2 | Size | 300x300x10mm 457x457x20mm 600x600x20mm 2800x1600x25mm, or as customer require |

| 3 | thickness | 25px, 50px, 75px, 100px or other thickness your requirement |

| 4 | Color | grey, red, white, yellow, black, coffee, beige, green, ect |

| 5 | Finished | honed, polished, sandblasted bush hammered, rough picked, Mushroom, Axe-cut, etc. |

| 6 | Application: | Skirting,Tread & Riser stairs, Bollard, Column,Curbstone, Paving,Flooring,etc Window sill, Kitchen top, counter top, Vanity top, Work top,etc Statue, Tomb and Monument,etc Wall cladding Cube,Border,etc |

| 7 | Payment terms | T/T 30%deposit and 70%balance(pay against B/L copy) or negotiation |

| 8 | Packaging | Thick tiles are packed directly in wooden crates, with safe support to protect the surface& edges, then in strong wooden crates. |

| 9 | Quality | All stone edges without breaking angle, no crack. |

| 10 | Min. Order | One 20GP container,Small order is acceptable, we can ship it by LCL shipping to your destination |

| 11 | Delivery time | According to your purchase quantity |

| 12 | Place of original | Fujian,china |

2. Advantages

Fast delivery with good price.

3. Pictures

4. FAQ

How about delivery time?

40~50 days.

How about MOQ?

100sq.mt per pattern.

- Q:Why is the quartz stone countertops more expensive than marble?

- (actually marble granite) the material cost is low, so the price is low, but the disadvantages are also obvious, basically all is the heavy color, the joint is obvious, subject to the length of a cabinet, generally have one or two obvious seams. Furthermore, there are gaps in natural stone, will penetrate the oil, with a long time, how do you clean the table, you will feel the oil, and easy to breed bacteria. In addition, with the improvement of people's living standard, more and more attention has been paid to the problem of environmental protection.

- Q:What is stone crystallization maintenance?

- The whole floor grinding: marble glue after drying and grinding grinding on the overall use of the ground machine, the whole horizontal grinding, grinding key caulking glue at the stone between (corner stone between) and close to the wall, decorative style, special shape at the edge of the stone floor to keep the overall smooth, polished finish again and again for marble glue caulking caulking finish to continue for second times and then polished stone retreading machine with steel mill stone tablets from coarse to fine, a total of seven times to complete the burnish surface overall smooth, with steel wool polishing, polishing to achieve the design requirements of the degree of brightness (70 degrees), no obvious gaps between the stones.

- Q:What kind of natural marble? How to choose?

- Check the quality of appearance: the appearance of marble plates with different grades are different. Because marble is naturally formed, the defect is inevitable. At the same time, the advantages and disadvantages of processing equipment and measuring tools is also the cause of the plate defects. Some plate plate not plump (warping or depression), plate defects (cracks, blisters, stains, etc.) plate specifications (such as a board body is not the lack of edges, etc.). In accordance with national standards, the level of marble plates are allowed to have some defects, but not so obvious excellence.Select the pattern color: marble plate color spot LAN, color diversity, patterns are not the same, this is the marble plate of the precious charm. The tone is basically the same, the color difference is small, the pattern is beautiful is the specific performance of good varieties, otherwise it will seriously affect the decorative effect.Detection of surface gloss: marble board surface gloss level will greatly affect the decorative effect. General quality polishing marble plate surface shall have a mirror like luster, can clearly reflect the scenery. However, because of the different chemical composition of different quality marble, even with the same level of products, the difference in gloss will be great. Of course, the same material between different grades of the board surface gloss will have some differences. In addition, marble plate strength, water absorption is also an important indicator to evaluate the quality of marble.

- Q:What is the smallest marble radiation?

- Marble radiation, and the deeper the color, the greater the radiation, less than 10 years, more than 30 years, the radiation is also a trend of attenuation.

- Q:What are the advantages and disadvantages of imitation marble tiles

- At first the market imitation marble texture mostly from Italy, first entered the market is basically the tiles, now have to polish or semi polished change, this change makes the brick surface look more luxurious and better visual effects. The texture of ceramic tile is natural and fresh, and the color and natural marble can almost be false. Complete marble is to do the body and glaze decorative uniform, simply do not come out.

- Q:Artificial marble on the back, how?

- Or wipe with liquid detergent. Use lemon juice or vinegar to clean dirt, but should pay great attention to. Lemon stays at the best time not more than 1-2 minutes. Do not place the lemon for a long time to absorb the marble, if necessary, repeat operation. And then clean and dry. For minor abrasions, use a special marble cleaner and care agent. For old or valuable marble furniture should be handled by professionals.

- Q:Do cabinet with artificial stone or marble good

- The grade of artificial stone is arranged from high to low as follows: acrylic artificial stone, composite acrylic artificial stone, aluminum powder polyester artificial stoneAcrylic artificial stone table belongs to the high-end table, the price is very high, here the rat will not do the analysis of the ~ ~ ~Composite acrylic artificial stone table price is much lower compared to acrylic, and the performance of polyester artificial stone than to be higher, there are more high temperature resistance and toughness.Aluminum powder polyester artificial stone is currently on the market more popular, environmentally friendly non-toxic, non radioactive, and has excellent processability and mechanical properties, oil resistance, non cracking, fire retardant. Compared to the price of acrylic composite is relatively low, and therefore belong to the artificial stone table class price is relatively high.Calcium powder polyester artificial stone countertops are low-grade countertops, because calcium powder ore powder, so may contain radioactive products; processing performance is poor, easy to collapse edge chipping; poor mechanical properties of finished products is fragile, easy to crack, short service life; poor anti pollution, easy to absorb water and oil and the formation of combustible fire spots.

- Q:How can a color penetrate into marble

- To remove stains from the marble, remember to use a neutral cleaner, not those with bleach. Do not use hard brush and abrasive cleaning agent. Like other stone, the best way is to prevent stains promptly clean up spilled marble liquid. Some owners will use a variety of different sealant to protect the marble surface, but in any case, should be regularly re sealed.

- Q:How to repair the marble furniture

- Cover a layer of putty powder to the corroded marble, wipe with a soft cloth, and then fold the cloth in half, repeat the process. If more professional work requires the use of electric polishing machine.

- Q:Marble how should maintain?

- In addition, after polishing the marble is hard, but the public or Home Furnishing marble ground, in use after a period of time because the outside world increasingly into the sand of the marble surface hardness is higher than the surface, will wear. At the same time, due to the lack of scientific knowledge and protection of the marble, the ground is hard to pull the sharp objects when the ground is not protected, resulting in partial scratches on the ground.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Natural Marble with Pattern in Different Size

- Loading Port:

- Fuzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products