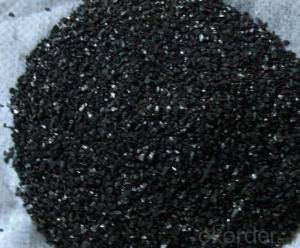

natural graphite powder,graphite products High-Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Provide various packing options according to customer requirements. |

| Delivery Detail: | 10-60 days according to order |

Specifications

1.Fixed Carbon 94%-99%

2.50, 80,100, 120,150,200,325 mesh

3.High purity flakes graphite

4.24 years experience

Natural Flakes Graphite Series

Advantage:

Perfect crystallization, great size in flake, high density, low content of mica, high luminance, excellent physical properties, such as resistance to high temperature, electric and thermal conductivity, self lubricity, and superior chemical stability

Size:

Adjustable to meet customer requirements, and major sizes include 50, 80,100, 120,150,200,325 mesh

Packing:

Provide various packing options according to customer requirements. Including Woven Bags, Paper Bags and Plastic Bags of 25KG, 50 KG, and 1000KG.

Technical Specification For Medium Carbon Graphite | |||||

Brand No. | Specification | ||||

Fixed Carbon (≥%) | Volatile (≤%) | Ash (≤%) | Moisture (≤%) | Remains on Sieve (%) | |

LG50-94 LG80-94 LG100-94 LG120-94 LG150-94 | 94 | 1.2 | 4.80 | 0.50 | ≥80.00 |

LG(-)100-94 LG(-)200-94 LG(-)325-94 LG(-)500-94 | ≤20.00 | ||||

LG50-95 LG80-95 LG100-95 LG120-95 LG150-95 | 95 | 1.2

| 3.80 | 0.50 | ≥80.00 |

LG(-)100-83 LG(-)200-83 LG(-)325-83 LG(-)500-83 | ≤20.00 | ||||

LG50-96 LG80-96 LG100-96 LG120-96 LG150-96 | 96 | 1.2 | 2.80 | 0.50 | ≥80.00 |

LG(-)100-96 LG(-)200-96 LG(-)325-96 LG(-)500-96 | ≤20.00 | ||||

LG50-97 LG80-97 LG100-97 LG120-97 LG150-97 | 97 | 1.20 | 1.80 | 0.50 | ≥80.00 |

LG(-)100-97 LG(-)200-97 LG(-)325-97 LG(-)500-97 | ≤20.00 | ||||

LG50-98 LG80-98 LG100-98 LG120-98 LG150-98 | 98 | 1.00 | 1.00 | 0.50 | ≥80.00 |

LG(-)100-98 LG(-)200-98 LG(-)325-98 LG(-)500-98 | ≤20.00 | ||||

LG50-99 LG80-99 LG100-99 LG120-99 LG150-99 | 99 | 0.70 | 0.30 | 0.50 | ≥80.00 |

LG(-)100-99 LG(-)200-99 LG(-)325-99 LG(-)500-99 | ≤20.00 | ||||

- Q:How to calculate the daily consumption of coal in power plant

- Coal consumption = installed capacity * design standard coal consumption / actual calorific value of coal;

- Q:1 degrees of electricity consumption of multiple coal?

- This figure is about 10 years ago, is a g of about more than and 400, but also a little more than G.In addition, there are differences in the quality of coal. It is not accurate enough to divide only by weight.Anyway, 300-400g, we first have a concept.

- Q:What is the role of activated carbon in the process of water purification

- Physical adsorption, clear after the coarse filtration / precipitation / softening after the last process: adsorption of fine insoluble and odor.

- Q:70 square meters of housing need to buy how much activated carbon

- The quantity of activated carbon should be determined according to the content of formaldehyde and the quality of activated carbon.

- Q:What is the thermal stability of coal

- The thermal stability of coal refers to coal in high temperature combustion or gasification process on the stability degree of heat, which is coal under high temperature and keep its original size properties. Good thermal stability of the coal, to its original size. Combustion or gasification but not broken into small pieces in the combustion or gasification process, or broken less; and poor thermal stability in coal combustion or gasification process is rapidly split into small pieces or coal. This light is slagging in furnace, increasing resistance and bring out the material, reduce the combustion or gasification efficiency, heavy damage to the entire gasification process, and even cause shutdown accidents. Therefore, there are requirements of coal enough thermal stability.

- Q:How does coal rank?Level, price

- Anthracite: high fixed carbon content, high fire point (about 360 to 420 DEG C), high true relative density (1.35 ~ 1.90), low volatile yield and low hydrogen content. In addition to power generation, anthracite is mainly used as raw material for gasification (fixed bed gasifier) for the production of synthetic ammonia, fuel and briquette

- Q:How long the activated carbon tank. It will fail, there will be any fault

- Evaporative emission control system has an active carbon storage tank, fuel vapor from the fuel tank from the "TANK" mark into the carbon canister. Liquid fuel entering the carbon canister is stored in a tank at the bottom of the canister to protect the active carbon carbon from the top of the canister, while the fuel vapor is absorbed by the active carbon. When the engine is at idle speed above the running environment, air enters the canister through the upper air pipe, the fuel vapor was washed out from the air blowing carbon, and mixed into mixed gas is sucked into the intake manifold.

- Q:First of all, I would like to ask is: what is the need for steelmaking coal or anthracite coal? How much coal can be made of steel? Understand the answer or add friends do not understand this!! ~

- Although not directly using coal for steelmaking, steel and coal but it will be related, the front said, steel is mainly used for coke, and the coke is used in bituminous coal, coking coal, fat coal, lean coal, gas coal and bituminous coal mixture is heated to 1000 degrees which is made, will not be directly used coal for steelmaking, because many harmful components contained in coal and coke, clean, suitable for steel and iron. Because most of the iron and steel plants will be their own coking carbon, so steel mills generally need to say in front of the coal!

- Q:What are the uses of coal?

- 5) living with coal: the number of living coal is also large, accounting for about 20% of fuel coal.6 metallurgical power coal: Metallurgical power coal is mainly used for sintering and blast furnace coal injection, the amount of less than 1% of the coal used for power.

- Q:What is charcoal? How is it made?

- (1) the kiln, with mud kiln, filled with wood burning from the kiln door or door, the carbonization of wood in the kiln, volatiles escape and residual charcoal;(2) dry distillation, the distillation of wood. According to a quenching method of kiln, there are two kinds of black and white.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

natural graphite powder,graphite products High-Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords