Natural Flake Graphite Origin In Shandong Provience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

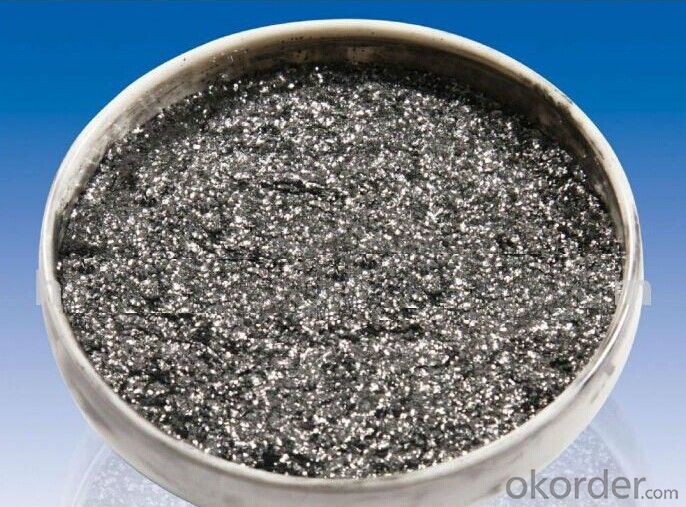

Natural Flake Graphite

Governmental Company

Good Quality& High Heat-resistance.

Competitive Price & Timely delivery

Product Description of Natural Flake Graphite :

1.Types:High-purity graphite,high carbon grahite.

2. Specifications:The particle size ranges from (325mesh-35mesh),and the carbon content ranges from85 to 99.9%.

PROPERTIES | CNBM-NFG1 | CNBM-NFG2 | CNBM-NFG3 |

Medium Carbon | High Carbon | High Pure | |

Carbon | 85-95% | 96%-99% | 99.9% |

Mesh | 45 μm-500 μm (325mesh-35mesh) | ||

V.M. | ≤4% | ||

Moisture | ≤0.5% | ||

Color | Black Shiny, | ||

Appearance | Flake | ||

Packaging & Shipping of Natural Flake Graphite :

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Purpose of Natural Flake Graphite:

natural flake graphite can be used as refractory materials, conductive materials, lubricating materials, casting, foundry, die and the high temperature metallurgical materials, a pencil core, and a hydrophilic material in petroleum and chemical industry, metallurgy, acid production, synthetic fiber, paper and other industrial sectors are widely used.

Natural flake graphite has excellent physical and chemical properties, in recent years, with the development of science and technology, more and more customers to use the natural flake graphite as lead batteries, lithium batteries negative pole conductive agent, nickel-metal hydride, nickel cadmium batteries, light battery, and graphite in atomic energy industry and national defense industry have a wide

- Q:How can the clinker graphite powder be dissolved in water?

- Rather, the clinker graphite powder is not dissolved in water, but dispersed into water.

- Q:What graphite powder made of graphite products, high hardness?! Wear-resisting! Good moisture! It can be made into graphite products at 100-200 degrees high temperature

- 100~200 C is not called high temperature for the preparation of carbon graphite products, but only resin can be prepared at this temperature.

- Q:Can graphite powder be used in lithium batteries?

- Because graphite powder is an important raw material for lithium battery production, graphite powder has conductive use, and graphite powder in conductive graphite powder is used to produce negative electrode materials for lithium batteries. Hope to help you, I hope to adopt, thank you.

- Q:Why is the battery electrolyte more potassium hydroxide and sodium hydroxide is less used?

- The solution of potassium hydroxide at a density of 1.25~1.27 (15 DEG C) is used at temperatures below -15. For the purpose of taking into account the low temperature performance and the charge holding capacity, the sealed nickel cadmium battery adopts an aqueous solution of potassium hydroxide with a density of 1.40 (15 DEG C). In order to increase the capacity and cycle life of battery, usually adding lithium hydroxide amount in the electrolyte (per litre of electrolyte and 15~20g).

- Q:Does graphite allow lubrication of rusted doors?

- Tolerable。 However, there is a premise: rust must be removed with rust.Lock force rust is generally not easy to lock inside the material easily rust off, then need to use oil to rust, rust removing, the graphite powder filling hole, and then the key to rotate back and forth, you can make the door lubrication.

- Q:Influence and protection of graphite dust on electrical equipment in workshop

- The graphite dust in the workshop is conductive, and the adhesion to the electric apparatus will affect the electrical insulation and lead to accidents. So we need to have the electrical box of graphite dust workshop to closed treatment, to prevent dust into the electrical cabinet.

- Q:Is the graphite powder produced with sulphuric acid?

- Graphite powder can smash through physical production method, also can be produced by sulfuric acid and other chemical methods, according to different types of graphite powder, the production process is not the same, I hope there is help for you, hope to adopt, thank you.

- Q:The graphite powder can replace thermal grease?

- Graphite is non-toxic, but graphite powder is harmful to human body; and graphite is used mostly in conductive products (common battery).

- Q:Graphite powder screening process, because with static holding together, resulting in vibration screen plugging network how to solve?

- The other is to install an electrostatic eliminator when the material falls into the vibrating screen. When the material is dropped, the powder static electricity is removed and the mass will not be assembled again.

- Q:How to measure the iron content in graphite powder?

- Take a certain amount of samples, adding dilute hydrochloric acid, excessive filtering and drying. The quality of the filter residue. By weighing the quality of the sample quality is the quality of minus slag containing iron. With this value divided by the sample quality, the mass fraction of iron.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Natural Flake Graphite Origin In Shandong Provience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords