Natural Coating Graphite Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100Ton kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

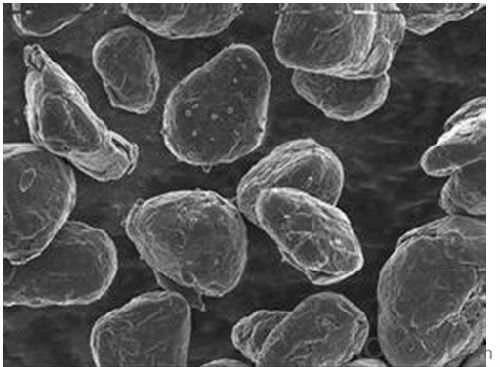

Coated graphite is the ball of Spherical Graphite oxide via a variety of approaches and methods were coated with stable electrochemical properties of cathode materials.

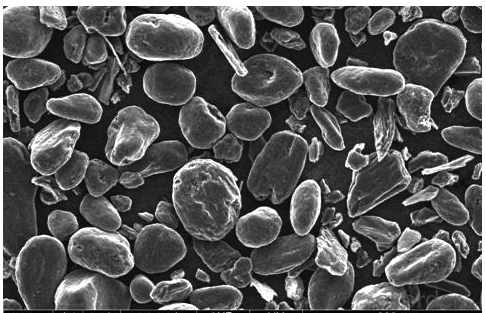

Crystalline flake graphite (or flake graphite for short) occurs as isolated, flat, plate-like particles with hexagonal edges if unbroken and when broken the edges can be irregular or angular

Amorphous graphite: very fine flake graphite is sometimes called amorphous in the trade.

2.Main Features

1. Low irreversible capacity

2. Good cycle life

3. High capability volume technology

4. Mature progressing technology

5. The good compatibility with the electrolyte application Scope: shell lithium batteries; cylindrical lithium batteries;

Polymer lithium batteries.

3.Specification

Item | Unit | Value |

(D50) Particle(D50) | µM | 8-32 |

Tap Density | g/cm3 | ≥1.10 |

Surface Area | m2 /g | ≤2.5 |

Moisture | % | ≤0.12 |

Ash | % | ≤0.10 |

Fixed Carbon | % | ≥99.95 |

First Coulomb Efficiency | % | ≥91 |

First Discharge Capacity | mAh/g | ≥350 |

Cycle Life | 500 ≥85% |

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

Q: Can you supply samples for us?

A: Yes we can send you sample with few quantity

Q: What is the delivery time?

A: One month since the payment will be received

- Q:What is the ratio of the coated sand to the graphite powder?

- Or change the sand species, change the high refractoriness sand species, this cost is relatively large.

- Q:Graphene with graphite powder where to do ah, high carbon content of the?.

- Look at the document, 45 microns will do. Good to buy. Preferably expanded graphite. But then again, if you buy graphite as graphene... The difficulty is not small

- Q:Graphite powder what is the difference?

- So the pencils are not made of lead, but made of graphite, which prevents the children from damaging their bodies by biting their pencil heads. Hope to adopt!

- Q:Can graphite powder be used in lithium batteries?

- Because graphite powder is an important raw material for lithium battery production, graphite powder has conductive use, and graphite powder in conductive graphite powder is used to produce negative electrode materials for lithium batteries. Hope to help you, I hope to adopt, thank you.

- Q:Can ultrafine powder iron conduct heat? How many purpose graphite powder can be called superfine stone powder? Pingdu graphite powder which good?

- In general, the average particle size of graphite powder is less than 10 m, you can call ultrafine powder toner, in fact, more than the use of ultrafine particles of toner, you can see Qingdao Huatai graphite, I hope to help you.

- Q:The axis and drum can use graphite powder lubrication

- No, graphite powder is suitable for high temperature environment, and the lubricating effect is better than that of lubricating oil

- Q:Phosphoric acid, two aluminium hydride, with graphite powder and mud

- Some of the key wavelengths off the chemical bond are shown below. The C-N bond is easiest to break, and the C-H bond is the hardest. You can also see that ultraviolet radiation can cause many chemical bonds to break. The activation wave length of some polymers is listed below. The data in the following table show that different polymers have different maximum damage wavelengths, and often the maximum damage wavelength is called the maximum activation wavelength. At this particular wavelength of light, the polymer can crack at the fastest rate.

- Q:Sunshine door lock winter treatment

- Always keep the lubricant in the locking part of the lock so as to keep the transmission smooth and prolong the service life. It is recommended to check it for half a year or one year, and check whether the fastening screws are loose or not, to ensure the fastening.

- Q:How can the antirust graphite powder used for locks be operated? Where is it painted?

- Check the locking gap between the lock body and the locking plate regularly, whether the lock tongue is matched with the height of the locking plate hole or not, the optimum clearance between the door and the door frame is 1.5mm-2.5mm. In case of any change, the position of the door hinge or the lock buckle shall be adjusted.

- Q:What binder does the graphite powder form with?

- Graphite powder is divided into natural graphite powder and artificial graphite powder, graphite powder made of graphite products, you need to add binders, binders useful for a variety of resins, asphalt and so on. 100~200 C is not called high temperature for the preparation of carbon graphite products, but only resin can be prepared at this temperature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Natural Coating Graphite Powder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100Ton kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords