Naphthalene Sulfonate Formaldehyde Condensate (NSF), 5%

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Naphthalene Sulfonate Formaldehyde (NSF/PNS)

(UNF-5 Na2SO4 ≤18%)

Description

UNF-5, a high range water reducer with no air entraining component, is also named as Naphthalene Sulfonate Formaldehyde Condensate (NSF), SNF, PNS, etc.. It complies with chemical admixture specifications for concrete: ASTM C 494, Type F; ASTM C 1017.

Application

1. UNF-5 is suitable to make autotrophic concrete, steam curing concrete, steel concrete and prestress concrete, all of which are made mainly of portland cement.

2. UNF-5 is applicable in areas with the daily lowest temperature of 0℃ and for making concrete which requires high fluidity, high strength or steam curing.

3. UNF-5 can be used to make C80 concrete with slump loss between 50mm and 70mm, or C60 concrete with that between 180mm and 220mm.

4. UNF-5 can be used as a raw material to compound accelerator, retarder, anti-freezing agent and pumping aid to satisfy requirements from different construction projects, techniques, materials and environmental temperatures.

5. UNF-5 is compatible with Portland Cement, Portland Slag Cement, Fly-ash Cement, Portland Pozzolanic Cement, etc.

Specifications

Items | Specifications |

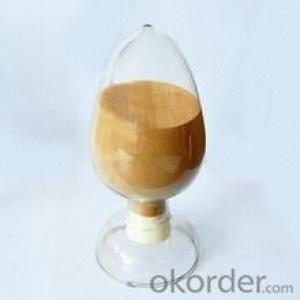

Visual Appearance | Light Brown Powder |

Moisture, % | 8.0 max |

Fineness (0.315mm remains), % | 15.0 max |

pH value | 8–10 |

Sodium Sulfate Content, % | 18.0 max |

Chloride Content, % | 0.1max |

Surface Tension | 68-72 Mn/m |

Cement Paste Flow | 230mm min |

Water Reducing Rate | 18% min |

Steel-bar Corrosion | None |

Features and Benefits

1. High water reducing rate: over 20%.

2. Saving cement without sacrificing slump retention and strength.

3. Good flowability.

4. Early and post strengthening ability.

5. Great compatibility with various types of cement.

6. Improved Compactness: it develops a better pore structure and makes the concrete more compact. It produces high durable concrete of which the anti-infiltrating index is beyond P18.

Uses and Dosages

It can be added during mix or after mix, while the afterward approach is preferential.

Dosage normally ranges from 0.5% to 1.0% by weight of cementitious material, while the recommended dosage is 0.75%.

Package

It's packed in woven fabric bag with plastic liner. Net weight: 25kg.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Naphthalene Sulfonate Formaldehyde Condensate (NSF), 5%

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords