MZ-B09D Plastic Lotion Pump with Multi Colour

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

lace of original | YuYao Zhejiang China |

Size : | 24/400 24/410 28/400 28/410 28/415 |

Material | New PP with SUS 304 H Spring inside |

Function | no leakage |

Discharge rate | 0.7+-0.05ml/T |

Packing | Strong carton packing suitable for long-distance transport |

MOQ | 10000pcs |

Delivery Port | FOB NINGBO,CHINA |

Payment Terms | T/T Irrevocable L/C at sight |

Lead Time | Within 20 days after reveived deposit |

Length or tube | Depend on your choice |

Sample | Available with fee |

Packaging | 800-1000pcs / carton ( 53x37x45 ) Qty 20'ft : 324,000pcs Qty 40HQ : 770,000pcs |

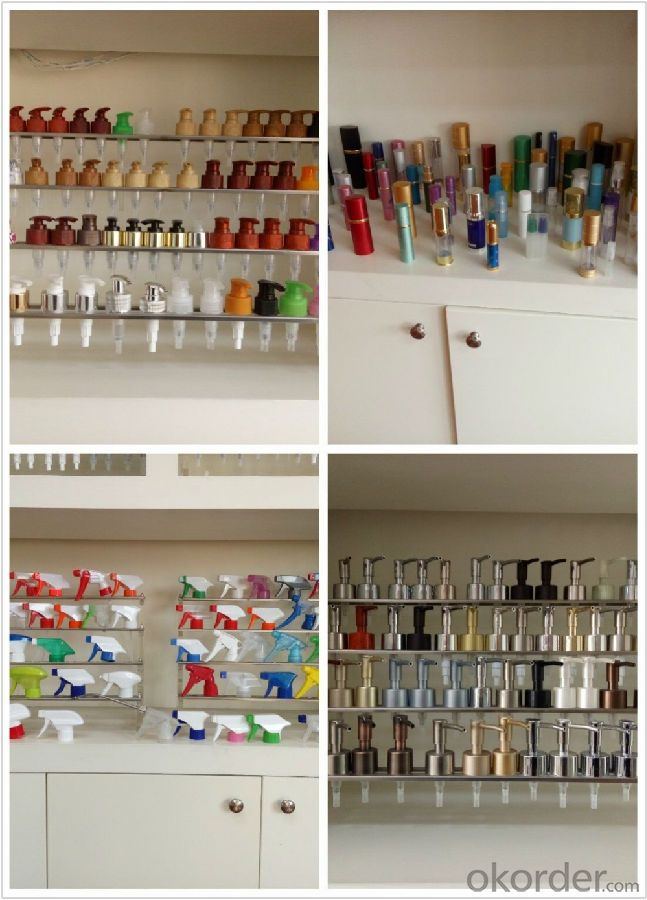

Product show

The Advantage of our lotion pump:

1) For the first using 3-4 times of pushing will workable

2) Multiple leakproof sealing design ensures that the product is not leaking, and provide maximum quality guarantee

3) Glass ball which resistant to acid and alkali

4) Non-Toxic pump meeting international standard requirements

5)The surface and internal of Lotion Pump is clean without dust, smooth, and color equality.

6)The design of the head of R Angle circular arc avoids the harm of manpower in use process, at the same time also increased the aesthetic feeling of product appearance.

7)The corrosion resistant performance of Spring is good, to ensure that greatly increase the service life.

8)We apply Sophisticated technology and go through environmental certification.

More than 12 years of experience in the R&D and production of bathroom and kitchen accessories. We are proud to be one of the very few manufacturers that can provide unique coating products and stainless steel pump.

* Innovative and fresh ideas are always welcomed by our design team. We strongly believe that the constant innovation is the key to the success and long-term development for our customers and us.

* A seasoned production team ensures us to provide our customers with high-quality products. Most of supervisors in our factory have more than 10 years of experience in the workshop management and plastic production.

* Equipped with the modernized production facilities, quality stability and reliability of products are effectively guaranteed.

FAQ

1) Can we get your free samples?

Yes, you can. Our Samples are only free for the customers who confirm order. But the freight for express is on buyer's account.

2) What is your shipping way?

We will help you to choose the best shipping way according to your detail requirements.

By sea, by air, or by express, etc.

3) What are the application of the product?

Lotion pump is applied on the bottles of facial cleanser,facial cream, hand cream,lotion , & liquid soap

4) Can we combine many items size in one container in my first order?

Yes, you can. But the quantity of each ordered item should reach our MOQ.

5)How long is the service life of the product?

The product warranty is 1 year.

Sample room

- Q:What's the material for the red wine lid?

- The cork is made of the bark of this oak. The bark is a protective layer of trees that is transported to the entire tree through the bark, so the average tree dies when it loses its bark. The cork is made of the bark of oak, which is because the soft oak has two layers of bark. The bark of the inner layer is vital and is the basis for the growth of new bark every year. As the old bark grows and dies, the new bark continues to take on the task of growth. Therefore, the dead bark of the outer layer can be stripped without hurting the trees, but in this process, be careful not to penetrate the vital inner bark.

- Q:How do I open the wine stopper without using a bottle opener?

- You can first find a nail or something like that, plug the plug open, so that the gas flow out, and then use chopsticks and things like that plug into the bottle inside, it will be OK!The best way is to buy a bottle opener, which is the best way:

- Q:What's the difference between red wine lids?

- Traditional power - Oak stopperThe most common bottle stopper, of course, is the traditional oak stopper. According to legend, the Greeks sealed the wine jar with a stopper in 500 bc. To understand the oak stopper, let's start with the oak tree. A healthy oak tree can live up to about 170 years old, mostly in Spain and Portugal on the west coast of the mediterranean. A young oak cannot be used to make a wine stopper, so it is not until the age of 42 that the bark is harvested for the first time to make wine plugs and then cut once every 9 years. Beginning in late May is the harvest season, two robust and strong workers from the same tree skillfully cut down large pieces of bark, their movements carefully, so as to avoid harm to the trees and bones, at least 35% bark to cover the trunk. Write down the next harvest year on the tree trunk before you leave. Freshly harvested oak bark can not be used immediately, and after 6 months of wind, water, cooking, disinfection, drying, and so on, the complex process can eventually be made into a qualified bottle stopper. Such harsh growth environments, lengthy cycles, and complex processes are no easier than bottles of wine.

- Q:How can I open the beverage bottle easily?

- The most simple method, on the bottom of the bottle, then push unscrewed the cap on the line.

- Q:Are wine made from plastic corks all bad wines?

- Wine made from plastic corks is certainly not expensive! (manufacturers do so for the purpose of saving costs.) Of course, cheap is not necessarily equal to bad quality. To judge whether a bottle of wine is good or not, it should look at its quality rather than its bottle stopper. In fact, some wines with low natural corks are of poor quality. Finally, to tell you that wine with plastic stopper can not keep long, or taste will be affected.

- Q:How do I open the wine stopper without a bottle opener?

- Fold the towel on the wall, this is certainly not to be broken, wine bottle;

- Q:What about the bottle stopper for the wine?

- The bottle of wine is not able to come up, take a thin handkerchief on the bottle, shake the bottle, when a handkerchief wrapped around the plug, the plug will slowly move to the mouth of the bottle, let out a corner of her handkerchief, at least two corners, and tried to yank the plug, you can

- Q:The red wine bottle opener is screwed in, but the stopper is too tight to pull out. How can I pull it out?

- Carefully insert the cork into the cork with the bottle opener, but try not to pierce it to prevent the cork from falling into the wine when the cork is dry.

- Q:Can any laptop close the screen after closing the lid?

- A sensor inside a notebook. It's near the bearing, so you close the lid and turn off the screen. Of course, you can also set up

- Q:When the wine is opened, the stopper is on the bottle opener and cannot be finished at one time. What can be used to cover the wine bottle?

- It's best to use a vacuum wine stopper. A red wine stopper is the best wine to drink. It can pump all the air out of the bottle and plug it firmly, so as to think of the red wine which has not been opened.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

MZ-B09D Plastic Lotion Pump with Multi Colour

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords