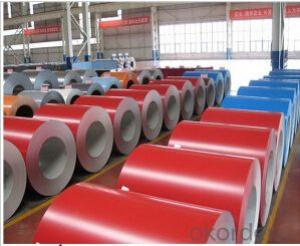

Myarman 0.16*914mm PPGI Prepainted Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Coated

Certification:ISO, SGS, BV, RoHS, IBR

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Construction Material

Edge:Mill

Stock:Stock

Steel Grade:Dx51d, SGCC, Sgch, A653, Dx52D, Dx53D

Place of Origin: China

Width:600mm-1500mm

Thickness:0.13mm-0.8mm

Length:Customered

Delivery Time:15-30 Days

Zinc Coating:30-275G/M2

Top Color Coating:10-25

Bottom Color Coating:7-10

Export Markets:South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia

Additional Info.

Trademark:MALIKE OR OEM

Packing:Standard Seaworthy, Export Packing

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin: China

HS Code:7210700000

Myarman 0.16*914mm PPGI prepainted steel coil

Product Description

0.13-0.7mm 700-1250mm galvanized steel coil, galvalume steel coil, prepainted galvanized steel coil,prepainted aluminium steel coil,

| NAME | GALVANIZED | GALVALUME/ALUZINC | PPGI/PPGL |

| MODEL NO. | (0.13-1.2)mm*(600-1250)mm | ||

| TYPE | steel coil, steel sheets/ plates, corrugated steel sheets/plates | ||

| TECHNIQUE | Hot rolled-cold rolled-galvanized | hot rolled-coldrolled-galvalume /Aluzinc | Hot rolled-cold rolled--galvalume/galvanized - PPGL/PPGI |

| SURFACE TREATMENT | Mini/regular/ big/zero spangle, ,Chromate treatment/ chromate-free treatment/ untreated Unoile/ oiled ,TENSION LEVELLERT SKIN PASS anti-fingerprint/Un-anti-fingerprint, coating | Polyester(PE),Silicone Modified(SMP),Acrylic (AC), Polyurethane(PU)PVC Plastisol(PVC plastisol can be embossed to versatile texture)etc | |

| APPLICATION | Guardrails, ventilation ducts, gutters and down spouts, Pre-paint and post paint applications, gutters and down spouts, ceiling suspension bars, shutter door rails. Auto parts, electrical appliances, refrigerator appliances, signs, automotive parts,vending machines, washing machines, showcases and other structural use, roofing, commercial use | Gutters, auto parts, electrical appliances, vending machines, refrigerators, ovens, for pre-paint. structural use, roofing, commercial use etc | Electrical appliances, roofing, partitions. Factory buildings, elevator panelsetc Special applications: wear resistant steel, high-strength-steel plate |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q:How are steel coils welded together?

- Steel coils are typically welded together using one of two methods: either by resistance welding or by arc welding. In resistance welding, the coils are pressed together and an electric current is passed through them, generating heat and causing the coils to fuse together. Arc welding, on the other hand, involves the use of an electric arc that melts the edges of the coils, creating a molten pool. As the pool solidifies, the coils bond together, forming a strong weld. Both methods ensure a secure and durable connection between the steel coils.

- Q:What are the applications of stainless steel coils?

- Stainless steel coils have a wide range of applications due to their durability, corrosion resistance, and versatility. They are commonly used in industries such as automotive, construction, aerospace, and food processing. These coils are used for manufacturing parts, components, and equipment like kitchen appliances, automotive parts, building materials, surgical instruments, and storage tanks. Additionally, they are utilized in heating, ventilation, and air conditioning (HVAC) systems, as well as in electrical and electronic devices.

- Q:How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems to create various components such as gears, shafts, and bearings. These coils are often transformed into flat sheets or strips, which are then shaped and processed to form the required parts. The strength and durability of steel make it an ideal material for transmission systems as it can withstand the high stress and torque associated with transmitting power from the engine to the wheels efficiently and reliably.

- Q:What are the challenges in coil slitting?

- Coil slitting, also known as coil cutting, involves the process of cutting large metal coils into narrower strips. However, there are several challenges associated with this process. One challenge is maintaining precision during slitting, as any deviation can result in uneven strip widths or poor edge quality. Another challenge is managing the tension of the coil throughout the slitting process to prevent material distortion or breakage. Additionally, handling and transporting the slit coils can be challenging due to their length and weight. Overall, ensuring accuracy, maintaining proper tension, and effectively handling the slit coils are some of the key challenges faced in coil slitting.

- Q:How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of rigorous testing, adherence to industry standards, and effective quality control measures throughout the manufacturing process. This includes conducting various tests such as chemical composition analysis, mechanical property testing, and surface inspection to verify the integrity and durability of the steel coils. Additionally, implementing strict quality control protocols, regular inspections, and continuous improvement initiatives are essential to ensure consistent and high-quality production of steel coils.

- Q:so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- it all depends nylon is faster, and brighter than steel, but is available only on acoustic as coil pickups won't detect them(only peizo will). That is one reason. Another is price, you tend to replace the nylon more often as it is weaker, and less resistant to corrision. EVEN THOUGH strings have a larger price range, and be cheaper than steel, or considerably more expensive. overall the nylon is brighter, but quite-er. Steel is louder, but deeper. nylon doesn't get feedback as easily, and is amazingly fast and easy to play. some think nylon sounds old fashoined(it looks it too, with an open headstock, ond classical look(sometimes mistaken as another name for it). MY SUGGESTION- visit your local music shop and try out steel, and nylons to in person get a feel for the sound.(remember that you get what you pay for, go as high in price as you can reasonably afford) ALWAYS TRY BEFORE YOU BUY, PLAY BOTH TYPES IN THE SAME RANGE OF PRICE(at least $400), THEN DECIDE WHAT SOUNDS BETTER TO YOU(and of course feels better and easier to play).

- Q:How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment, such as automobiles, ships, and trains, to create various structural components. These coils are typically shaped and formed into parts like chassis, frames, bodies, and panels, providing strength, durability, and stability to the vehicles. Additionally, steel coils can be used in the manufacturing of wheels, axles, and suspension systems, ensuring reliable performance and safety in transportation equipment.

- Q:How are steel coils inspected for paint adhesion using adhesion testers?

- Steel coils are inspected for paint adhesion using adhesion testers by applying a controlled amount of force to a specially prepared test area on the coil's surface. The adhesion tester measures the amount of force required to remove the paint coating from the surface, providing a quantitative assessment of the paint adhesion. This process helps ensure the quality and durability of the paint coating on the steel coils.

- Q:so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- I, too, don't like stainless steel because it is so hard to keep clean. Bar Keeper's Friend really does become your friend when you cook on stainless steel. It will remove the burnt on food, remove the dark brown stains and keep it looking new, however. And, it won't void most manufacturer's warranties on the cookware. It just takes the elbow grease to do it every time you use it. I found it is necessary to use more olive oil than you think is necessary, a lower flame than most recipes call for and a lot of patience if you plan to use it on a daily basis. I went back to my non-stick Calphelon because I am not a patient woman, I like instantaneous gratification and hate scrubbing pots and pans!

- Q:I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- Good steel ain't cheap, cheap steel ain't good... If you're just starting out (practicing anyways), I would be less concerned about the material and more concerned about the style and shape of the blade to gain consistency in your technique... When you start getting proficient for competitions and such... then I'd start investigating steel grades... Anyways, here's a summary from the wiki: Type 440—a higher grade of cutlery steel, with more carbon, allowing for much better edge retention when properly heat-treated. It can be hardened to approximately Rockwell 58 hardness, making it one of the hardest stainless steels. Due to its toughness and relatively low cost, most display-only and replica swords or knives are made of 440 stainless. Available in four grades: 440A, 440B, 440C, and the uncommon 440F (free machinable). 440A, having the least amount of carbon in it, is the most stain-resistant; 440C, having the most, is the strongest and is usually considered more desirable in knifemaking than 440A, except for diving or other salt-water applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Myarman 0.16*914mm PPGI Prepainted Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords