Multilayer Heat Insulation Cover Paper for Cryogenic Piping System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Jiangsu, China (Mainland) | Brand Name: | HAOLIS | Model Number: | customized |

| Application: | Cryogenic liquid container() | Surface Treatment: | raw material | Technique: | vacuum aluminium |

| Dimensions: | 10-14g/m^2 | color: | white | material: | glass fibre paper and aluminium foil |

| working temperature: | -269℃-500℃ |

Packaging & Delivery

| Packaging Details: | in roll/ in cartons /in bales 1. Tarpaulin Rolls: 20GP Load around 15tons. 2. Bale packing: 20'GP Load around 10 Tons , 40'HQ Load around 25 Tons. 3. Carton packing: 20'GP Load around 8 Tons , 40'HQ Load around 22 Tons. |

| Delivery Detail: | 10-20days after payment |

Specifications

Aluminium foil/film+pe woven cloth( single alu)

Aluminium foil/film+ pe woven+ aluminium foil(both sides alu)

Characteristics:

No odor and to xicity, environmentally-friendly;

Light, soft, dustfree, fire, retardant, easy to install;

Heat reflection, heat insulation, sound insulation, anti- radiation, anti- vibration, and shielding;

high Adhesion Strength super Holding Power good Conductivity CTI certificated.

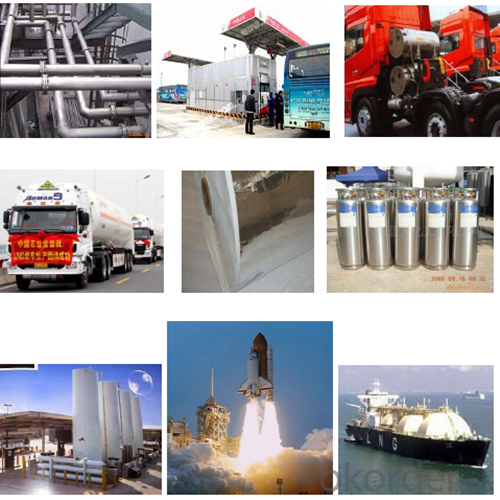

Application

1.As heat and light (radiant) barrier for the roofing of housing;

2.As the interlayer between floor and the ground to prevent moisture and heat;

3.As an disposable and budget underlay insulation material for carpets;

4.As protective outer package for industrial machines, vehicles and home appliance

UV additive can be added according to different requirement.

FR additive can be added according to different requirement, FR standard can reach US CPAI-84 FR7 standard.

* Note : These are our standard specifications but products with customized specifications are also available.

- Q:What is a cryogenic fast line

- Equipment is compressor, heat exchanger and expander (or throttle). The compressor and expander generally use a reciprocating or turbine. Commonly used heat exchanger coil type, shell and tube type or plate heat exchanger. Deep freezing technology, can the nature of the study of materials near absolute zero, and can be used for the separation of liquid and gas mixture of gases. Industry can get liquid oxygen, liquid, gas, etc.; Can be effectively separated from the air

- Q:Cryogenic treatment to improve what performance?

- Cryogenic treatment (cryogenic treatment) refers to the materials needed at -190 DEG C to -230 DEG C under treatment. Suitable for all metal or nonmetal material, such as alloy, carbide, plastic (nylon and Tie Fulong), aluminum, ceramics etc..

- Q:How many changes in the properties of the cryogenic metal?

- 10 diamond drill footage of 231.2 meters to 595 meters.11 M6 high speed steel fibers processing aluminum casting parts 1200 40012 high speed steel milling cutter cutting area of copper 350 pieces of 750 pieces13 cutting blade YT798 area A3 51 square meters to 98 square meters14 cutting blade YT798 area ZG15Gr1M01 7 square meters to 12 square meters15 YT330 blade ZG15Gr1M02 for 6 minutes 19.8 minutes16 YT15 blade cutting length 20# low carbon steel 3M 7M17 YT30 blade cutting length 20# low carbon steel 5m 9.7M

- Q:I would like to ask how the process of cryogenic treatment

- It's just a rough process of producing oxygen through cryogenic technologyNitrogen can also be re cooled into liquid nitrogen -196 degrees.Liquid nitrogen can be used for some cryogenic treatmentIf the temperature is lower, can use liquid helium.Cryogenic applications

- Q:What is the meaning of vacuum cooling in heat treatment

- In order to eliminate residual austenite after heat treatment, after quenching or tempering

- Q:What is the meaning of deep frozen

- In general, the frozen layer of our home refrigerator can only reach -18 degrees, but also slow freezing, slow freezing will have a great impact on food nutrition and flavor.

- Q:Can the cryogenic phase control the cooling rate?

- 1, the principle of liquid nitrogen refrigeration: storage of liquid nitrogen in the container through the liquid in the sublimation of heat to take away the heat of the workpiece heat. Liquid nitrogen refrigeration can not be reused after the need to add a new liquid nitrogen, a large range of cooling rate, cooling temperature range of 0-196 degrees C.

- Q:What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- High speed steel W18Cr4V cryogenic hardness, impact toughness and wear resistance are significantly improved with the use of its manufacturing tool life increased by 2~5 times

- Q:Ultra low pressure casting mold useful, how to arrange the process? Thank you

- While casting field production high temperature is about 660 degrees, some die casting production Aluminum Alloy temperature of 740 degrees, copper alloy die-casting production temperature even up to about one thousand degrees, the temperature and the ambient temperature, the temperature fluctuation is bigger, hot and cold alternating stress caused by the greater! That is, the stress produced in the production process is very large, even if the cryogenic treatment, the stability of the role of the size of the casting mold and plastic mold is not obvious! As for how you choose, you might as well try!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Multilayer Heat Insulation Cover Paper for Cryogenic Piping System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords