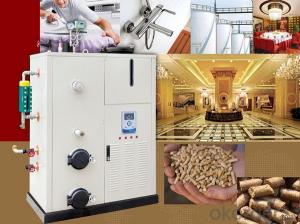

Multifunctional Biomass Pellet Cooking Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.8~15KW Cooking Stove

2.1025x550x715mm

3.Can be customized

4.Biomass Pellet Fuel

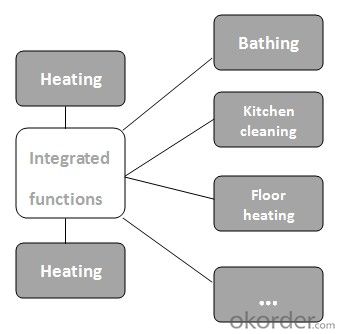

5.Multi Functions In a machine

Introduction

Multifunctional biomass cooking stove is a well-developed high-end product by us. This series produced in order to response to national policy, namely encouraging clean, efficient development and utilization of biomass, turning “waste” into wealth. This product can replace traditional oil / gas stove and backward household mud stove which being used in hotels and other industries. It is a multi-purpose stove, can be used for cooking, boiling, heating, etc. Wok, steamer, pressure cooker, kettle and other kitchen utensils can be put on the top of the stove, to meet different needs.

Key Features

Strong thermal power: stove flame temperature can reach to 1,000 degrees when sufficient burning.

Clean and green: Burning ashes are all access to the hopper, no smoke and dust in operating room.

Beautiful appearance: product’s outer packing boards are all use molding, soft colors, beautiful appearance.

Fuel advantage: suitable for straw, wood and other biomass briquette, low operating cost, save 40% than gas stove, 50% than electric stove province, 60% than oil furnace

Application Range

Widely used in hotels, snacks, canteens, factories, rural families, bath, warming, floor heating, etc.

Specification

| Project | Unit | GS-1-M |

| Design out of water | kg/h | 200~300 |

| Available fuel | / | Biomass pellet fuel |

| Overall size | mm | 1025x550x715 |

| Design power | KW | 8~15 |

| Reference heating area | m2 | 60~70 |

| Fuel consumption rate | kg/h | 1.5~3 |

| Weight | kg | 115 |

Note:

1.The data is for reference only, technical specifications may be subject to change without prior notice.

2. Our products can be customized. If any other parameters are needed, please contact me.

FAQ

Q:What's my consideration when i choose a gas stove?

A: -The style and size of your kitchen.

-The food or cooking style you prefer.

Q:Can i be a distributor of CNBM?

A: Of course you can.

Q:What are the benefits of being your gas stove distributor?

A: - Marketing protection.

- Priority of launching new design.

- Point to point technical supports and after sales services.

Q: How can i become a distributor of CNBM stoves?

A: Contact us immediately for further details by sending us an inquiry.

- Q:What are the methods of biodiesel production?

- 2, biological method3, chemical catalytic method(1) one step (one step process)(2) the two step method

- Q:What are the benefits of waste oil for biodiesel production in energy saving and emission reduction

- By the reaction of fatty acid to Biodiesel: RCOOH + CH3OH = RCOOCH3 + H2O from triglycerides to reactive Biodiesel: C3H5 (RCOO) 3 + 3CH3OH = RCOOCH3 + C3H5 (OH), 32 common methods of biodiesel production process of chemical production, plant and animal oils with methanol or ethanol low carbon alcohol in the presence of a catalyst for the esterification reaction of fatty acid esters of biodiesel. The project uses waste oil (or waste oil) and methanol as raw materials, the use of independent research and development of a one-time composite catalyst for biodiesel production. The production process is divided into four steps: pretreatment, esterification, glycerin refining, biodiesel distillation.

- Q:What are the sales of biodiesel in China in recent years?

- By azeotropic distillation glycerol esterification esterification technology, using waste production of bio diesel oil, waste oil to achieve efficient reaction of free fatty acid esterification and interesterification of oils and fats, opened up a new way of waste oil into biodiesel. At present, developing new technology, new technology including high-pressure alcoholysis complete double solvent process, ultrasonic catalytic transesterification of ester exchange process, solid base catalyzed transesterification process, all aspects of the research have yielded good results, further research and development which will undoubtedly contribute to biodiesel in china.

- Q:What is the use of Biogas

- Do not refuse to see the road, not pigsty dung, the roof not to take the "new socialist countryside scene smoke.

- Q:Compared with fossil diesel fuel, what are the advantages of biodiesel

- Has a good alternative performance: biodiesel can be used directly by existing diesel engines and diesel distribution systems

- Q:I have always wanted to do this project. Biodiesel is roughly what the plastic waste tire by biological effect into diesel. Do not know to have done this project to write comments? This project has not to do, or which company is trustworthy.Trouble you, I just graduated students do not want to lose their jobs after graduation

- At present, bio diesel in the domestic market, really in the biodiesel who earn money less, you are just graduated students please observe several years in involvement, if you blindly will Qing Tibetan home involvement because of bio diesel investment Nissan 30 tons of investment have reached more than 1 million you know, just for the bio diesel technology is still not understand very gullible, if you want to understand the industry recommend you to a biodiesel plant for a few years to do good work

- Q:If you want to produce bio diesel, what equipment to use better?

- At present, there is no national standard for biodiesel equipment, Wuxi Rui source of bio fuel equipment companies do this

- Q:Biodiesel can be used directly on the diesel car, or to be used in combination with petrochemical diesel?

- The power of the engine is not affected (this is positive), and because biodiesel contains oxygen, it will burn more fully and release more heatThe above is only a personal view, if there are different views, welcomed the discussion!

- Q:Biodiesel can be used directly as fuel for diesel engines

- Biodiesel can be used directly as diesel fuel additive

- Q:Biogas digesters and septic tanks in rural areas which utility

- Personally feel that if biogas digesters in rural areas than in the septic tank is useful, because not only produces biogas digesters (can cook, lighting etc.) and biogas residue and biogas slurry can also be used as a good fertilizer

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Multifunctional Biomass Pellet Cooking Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords